15358968703

Study on morphology and composition of dust collected from different processes in iron and steel smelting process

Abstract: a large number of pollutants will be produced in the process of iron and steel smelting. The annual emission of smoke and dust is huge. Particles are the main component of smoke and dust in iron and steel enterprises. In this study, the surface morphology and component content of dust collected from different processes of different enterprises in the process of iron and steel production are compared and analyzed. It is found that there are great differences in the composition and particle morphology of dust collected from different processes, The content of dust removal ash in the same link of different enterprises is also very different. The dust removal ash in all processes contains 14%~94% Fe2O3, which has a high value of graded recycling

Key words: steel smelting; Dust removal; Morphology; component

The iron and steel industry is a pillar industry of the country. It is also an industry with high energy consumption and high pollution. It has always been the focus of emission reduction and environmental protection Particulate matter is one of the main pollutants in the iron and steel industry. In recent years, the emission of particulate matter from the iron and steel industry has been the main emission in the industrial field At present, the limit value of sintering and pelletizing particles in sintering machine and pelletizing equipment is 50mg/m3, and the limit value in sintering machine tail, belt type sintering machine tail and other production equipment is 30mg/m3 [1] The emission standard of iron making particles is 20mg/m3 in the hot blast furnace, 25mg/m3 in the raw material system, cents system, blast furnace tapping plant and other production facilities [2] The emission standard of particles in steelmaking process is 50mg/m3 for converter (primary flue gas), 30mg/m3 for continuous ball cutting, flame cleaning, lime kiln and dolomite kiln roasting, and 100mg/m for steel slag treatment ³, The limit value of hot metal pretreatment (including conduit, slag raking, etc.), converter (secondary flue gas), electric furnace, refining furnace and other production facilities is 20mg/m3[3] The emission standard of particulates from steel bar is 30mg/m3 in hot rolling finishing mill and waste acid regeneration process, and 20mg/m3 in other facilities [4] In 2018, Hebei issued the latest ultra-low emission standard for the iron and steel industry. Except for the treatment limit of converter primary flue gas and steel slag of 50mg/m3 and the regeneration limit of waste acid of 30mg/m3, the emission limit of particulate matter in other processes is 10mg/m3, which is the most stringent standard in the global iron and steel industry [5] Although the total emission of smoke and dust from the iron and steel industry showed a downward trend as a whole, from 43.78% in 2012 × 105T reduced to 40% in 2015 × Below 105T, but up to 2017, the emission of smoke and dust is still 33.22 × About 105T, the quantitative analysis by MFA (material flow analysis method) shows that the emission of smoke and dust in the iron and steel industry is 648.08g/t steel [6-8]. The research and analysis of the dust in the whole iron and steel smelting process can provide specific control measures for tracking the dust source. However, at present, the dust research in the field of iron and steel metallurgy is mostly focused on the analysis and research of particles produced by a single process or link in the iron and steel industry, and there is little research on the systematic analysis and comparison of dust removal particles in different processes and links Based on the particle morphology and composition of dust collected from different processes in typical areas of Beijing, Tianjin and Hebei with high national environmental protection requirements [9-15], this paper studies and analyzes the relationship and differences between dust collected from different processes, in order to provide reference for the control and utilization of particles in the iron and steel smelting process

1. Test materials and methods

1.1 dust source

Aiming at the four major processes of coking, sintering, ironmaking and steelmaking, the dust collected from three steel plants in Beijing Tianjin Hebei region, including coke dry quenching, coke oven smoke and meat, sintering machine head, blast furnace tapping yard, blast furnace ore tank, hot metal pretreatment, converter dust removal and refining furnace dust removal, was sampled and analyzed

1.2 test method

The dust morphology was analyzed by SEM Take a sheet of metal, keep the surface clean, and stick the conductive adhesive to its surface After that, the dust sample is evenly scattered on the colloidal surface, and the nonadhesive powder is blown off with an ear washing ball SEM analysis was carried out after carbon spraying on the surface to observe the particle morphology

The composition of dust collected was analyzed by XRF Dry and grind the dust dust, and then analyze the dust composition with X-ray fluorescence spectrum analyzer

2. Results and analysis

2.1 morphology of dust particles in iron and steel enterprises

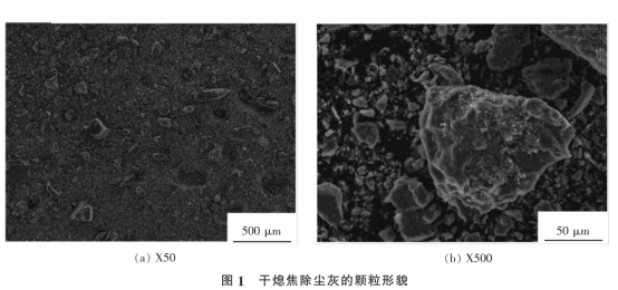

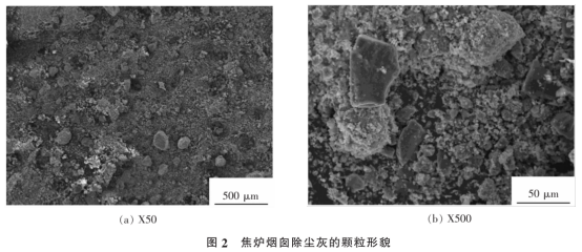

2.1.1 particle morphology of dedusting ash in coking process

The coke dry quenching dust and coke oven smoke dust were selected for SEM analysis in the coking process. See Fig. 1 and Fig. 2 for their surface morphology The comparison of particle morphology between CDQ dust and coke oven flue gas dust shows that the difference of surface morphology of dust in different links of coking process is mainly manifested in particle shape and size distribution Under the same multiple, the particle size difference of coke oven smoke dust is smaller than that of CDQ dust dust, there are a large number of block or plate-shaped particles, the surface is relatively flat, and there are a large number of foam particles, with bonding phenomenon The maximum particle size of dedusting ash from coke dry quenching can reach more than 100pm. The size of dedusting ash from coke oven smoke is relatively small, and the maximum particle size is about 50um

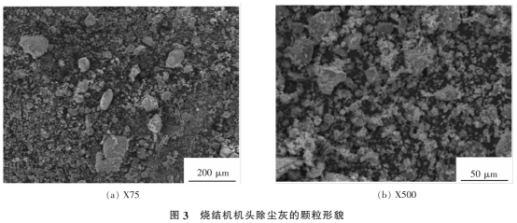

2.1.2 morphology of dust particles in sintering process

The morphology of dust particles in sintering process is shown in Figure 1, where (a) and (b) are SEM photos with different magnification It can be seen from Figure 3 that the dust collected from the sintering machine head is mainly composed of bean like particles and a large number of fine crumb like particles. The size of bean like particles varies greatly, and the maximum particle size can reach 200um. At the same time, there are adsorbents on the particle surface

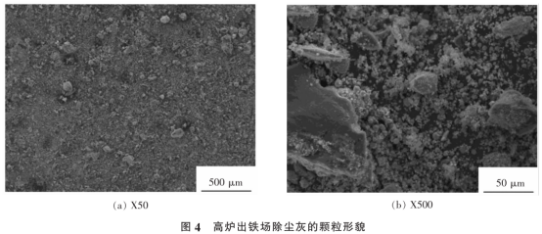

2.1.3 morphology of dust particles in ironmaking process

See Fig. 4 for the particle morphology of dedusting ash in the blast furnace cast house of ironmaking process

It can be seen from the figure that the dust collected from the blast furnace cast house is composed of irregular plate-shaped and block shaped particles, a large number of spherical particles and fine crumb like particles. Some of the block shaped particles have smooth and flat surfaces, and some of the surfaces have a large number of adherents. The maximum particle size can reach 150um.

2.1.4 morphology of dust particles in steelmaking process

The converter dust is the focus of the steelmaking process. The primary converter dust particles are coarse and the color is mostly black gray The particle size of converter secondary dedusting ash is fine and its color is mostly reddish brown See Fig. 5 for particle morphology of converter secondary dedusting ash

The secondary dedusting dust from converter can obviously see the existence of many particles with different shapes. Among them, the surface of bean shaped particles is very unsmooth, with a large number of spherical protrusions or adherents. Compared with the sintering dust, there are ridges and cracks At the same time, it contains a large number of irregular thin plate-like particles, with few surface adhesion, and the maximum particle size can reach 150um

2.2 composition analysis of dust removal ash

In order to find more efficient emission reduction and environmental protection technology, the composition of dust from various processes in iron and steel enterprises was analyzed Because there are great differences in raw materials and processes used by different enterprises, the composition and physicochemical properties of dust removal ash produced in the same process are also different X-ray fluorescence spectroscopic analysis was carried out on the dust collected from different processes of iron and steel enterprises in various typical regions. See Table 1 to table 10 for the test results The letters a, B and C in the table represent different regions.

2.2.1 composition analysis of dust from coking process

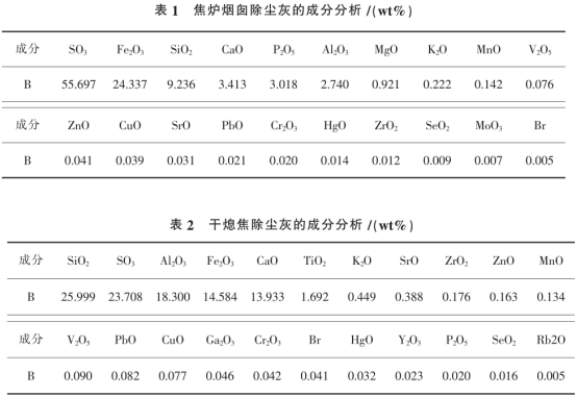

There are many kinds of air pollutants in the coking process, with large amount of smoke and dust viscosity. Among them, the coke oven has a large amount of coke dust, and the dry quenching has a large amount of dust, which needs to go through multiple dust removal links This study takes coke oven smoke and dry quenching as typical links. See Table 1 and table 2 for the composition analysis of dust removal ash

It can be seen from the table that the content of SO3 in coke oven smoke dust is the highest, about 55%, followed by Fe2O3, about 25%. Except for SiO2 content of about 9%, the content of other components is less than 4% The main components in the dust collected from CDQ are SiO2, SO3, A12O3, Fe2O3 and Cao, and the contents are about 26%, 24%, 18%, 15% and 14% respectively According to table 9 and table 10, the main components in different links of coking process dust removal ash are quite different. The main components of dry quenching dust removal ash include SiO2, CO3, Al2O3, Fe2O3, Cao, and a small amount of K20, MnO, MgO, etc; The main components of coke oven flue dust are SO3, Fe2O3 and SiO2, and the total content is more than 90% Compared with other processes of iron and steel production, the content of sulfur oxide in dust removal ash of coking process is relatively high

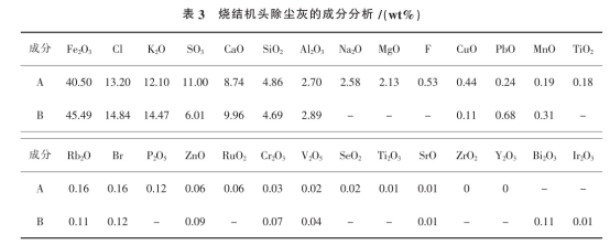

2.2.2 composition analysis of dust removal dust in sintering process

Sintering is an important process in the iron and steel production process, in which the annual ESP ash produced by the sintering machine head can reach 1500 × 105t. See Table 3 for composition analysis of dust collected from sintering machine head The XRF analysis results of sintering machine head dedusting ash show that the main component of sintering machine head dedusting ash is Fe2O3, the content of which is between 40%~50%. It also contains chlorides and a variety of oxides, including K20, SO3, Cao, SiO2, Al2O3, Na2O, MgO, etc. among them, the contents of alkali metal K2O and Na2O are 12%~15% and 0%~3% respectively. There is little difference in the content of main components in iron and steel enterprises in different regions

2.2.3 composition analysis of dedusting ash in ironmaking process

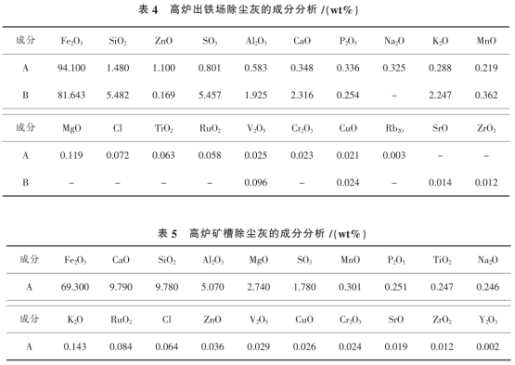

The parts where the particles are produced in the ironmaking process include the blast furnace casting yard, blast furnace ore trough, hot blast stove and other links. About 10million tons of blast furnace dust are produced in China every year. Its main component is high-temperature recycled ore, which is rich in C, Fe, Zn and other elements, and has high recycling value See Table 4 and table 5 for composition analysis of dedusting ash from blast furnace taphole and blast furnace trough

It can be seen from table 4 that the Fe2O3 content in the dust collected from the blast furnace cast house is the highest, up to 80%~95% In addition, there are many oxides such as SiO2 and SO3, all of which are within 6% The K20 and Na2O contents of dust removal ash are 0.2%~3% and 0~0.4% respectively, which is about 10% lower than that of sintering The content of Fe2O3 in ironmaking process varies greatly in different regions, and the content of other components does not differ significantly

2.2.4 composition analysis of dust in steelmaking process

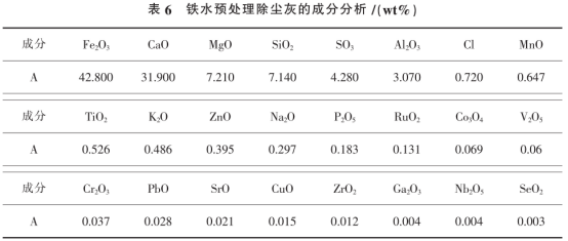

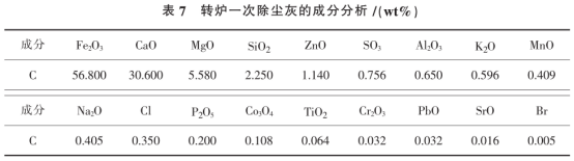

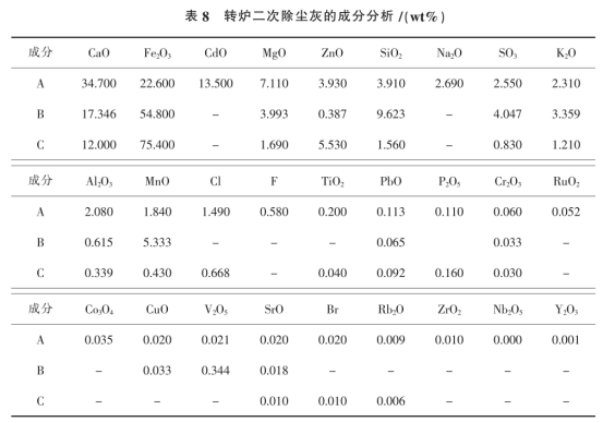

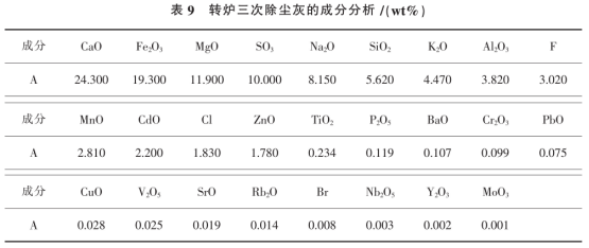

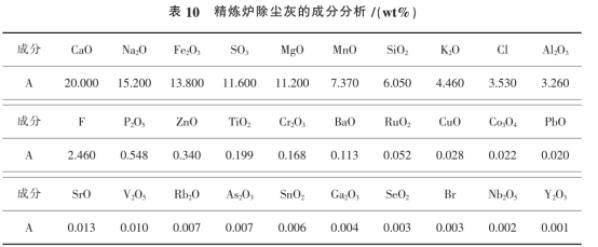

Particulate matter is the main air pollutant produced in steelmaking process. The main production links include hot metal pretreatment, converter, refining, etc The converter dedusting process is divided into primary dedusting, secondary dedusting, tertiary dedusting and other dedusting processes. The composition of dedusting ash in different links of the steelmaking process is shown in Table 4 to table 8

From table 6 to table 10, it can be seen that the main components of hot metal pretreatment dust are Fe2O3 and Cao, with the content of about 43% and 32% respectively; In addition, the contents of MgO, SiO2, SO3 and AI2O3 are between 3%~7.5%, and the contents of alkali metal K20 and Na2O are about 0.5% and 0.3% The content of Fe2O3, Ca0, alkali metal K20 and Na20 in the primary dedusting ash of converter is 57%, 30% and 0.6% and 0.4% respectively, which is similar to that of hot metal pretreatment dust, and the content of MgO and SiO2 is slightly lower than that of hot metal pretreatment dust The composition of converter secondary dedusting ash varies greatly in different regions, in which fe2o323%~76%cao content is 12%~35%, alkali metal K20 and Na20 content are 1%~3.5% and 0~3% respectively, showing an increasing trend compared with that of converter primary dedusting The content of Fe2O3, Cao and alkali metal K20 and Na2O in the dust collected from the third dedusting of converter is about 20%, 25% and 4.5% and 8% respectively. According to the composition analysis of the dust collected from the third dedusting of converter, the content of Fe2O3 is decreasing and the content of alkali metal is gradually increasing The content of Fe2O3, Ca0, K20 and Na20 in converter refining dust is about 14%, 20% and 4.5% respectively The content of alkali metal in refining furnace dust is the highest in converter process

3. Conclusion

1) The dedusting dust from blast furnace taphole, sintering machine head and coke oven smoke and meat is composed of a large number of irregular block particles and flocculent powder particles, and there are more adherents on the surface of large particles; The dedusting ash of CDQ is mostly composed of irregular block particles of different sizes, and the surface of some particles is relatively flat; The secondary dedusting ash of converter contains flake, block, bean and other irregular particles, as well as a large number of crumb particles

2) Compared with the four major processes of iron and steel production, the content of sulfur oxide in the dust collected from coking process is relatively high, the content of Fe2O3, C1, K2O, SO3 and Cao in sintering process is high, and the content of Fe2O3, SO3 and SiO2 in iron making process is high. The composition of dust collected from the same process in different enterprises is also different. The content of alkali metal in the dust collected from converter process increases with the increase of dust removal times, The content of alkali metal in the dust of converter refining furnace is relatively high, and the content of Fe2O3 and Cao is always high

3) Most of the dust collected from different processes contain considerable Fe2O3 and other components with recovery value, so it can be considered to recycle the dust by classification