15358968703

11 years' production practice of No. 8 blast furnace in WISCO

The effective volume of No. 8 blast furnace at WISCO is 4117m3. The hearth is lined with thin copper to cool the fireplace body, and the bottom is lined with composite carbon brick ceramic cups. It was put into operation on August 1st, 2009 and has been put into operation for 11 years. The blast furnace has maintained a good production rhythm and various indicators have been steadily improved. By 2020, the blast furnace has produced 40.6086 million tons of iron, with an average annual iron production of 3.5619 million tons. The iron production has reached 107.1% of the blast furnace design index (3.325 million tons). The accumulated iron production per unit volume is 9863.63t/m3, and the cumulative utilization coefficient has reached 2.36t/ (M3 · d). At present, Baosteel No. 2 blast furnace (furnace capacity: 4063m3), the representative of the longevity of China's 4000m3 blast furnace, has a first generation furnace life of 15 years, and the iron production per unit volume exceeds 10000t/m3. WISCO No. 8 blast furnace is expected to catch up with Baosteel No. 2 blast furnace in terms of high efficiency and long life in the 4000m3 blast furnace. Therefore, this paper focuses on the analysis of furnace shape design, blast furnace parameter adjustment and blast furnace hearth status of No. 8 blast furnace, so as to provide practical experience guidance for long-term and stable operation of domestic large blast furnaces.

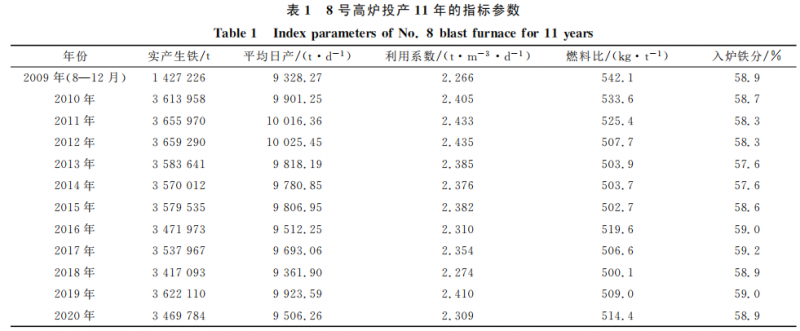

1. Main economic and technical indexes of blast furnace in 11 years of operation

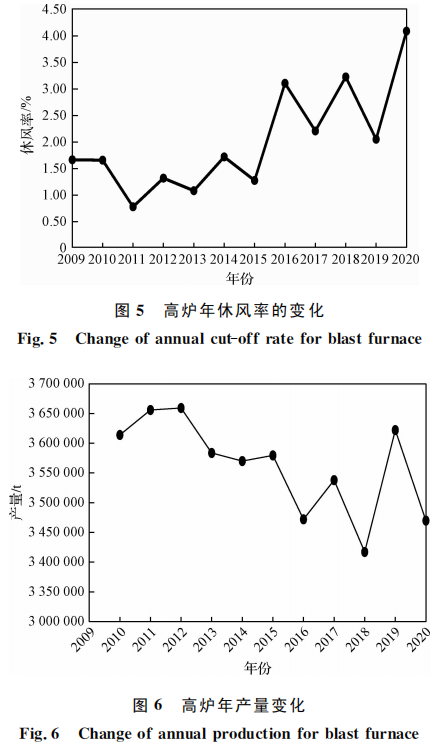

The No. 8 blast furnace has been operating at a good pace for 11 years. The main economic and technical indicators of the No. 8 blast furnace for 11 years are shown in Table 1. In the initial three years (2010-2012) and 2019, the annual iron output of the blast furnace reached more than 3.6 million tons. In particular, in 2019, the adverse factors of the fluctuation of peripheral raw fuel conditions were overcome through fine operation. When the blast furnace was put into operation for 10 years, it was still able to maintain an efficient production mode, fully affirmed the policy of "wind as the key link" in the parameter regulation of the blast furnace, "strong wind cures all diseases", and maintained a sufficient amount of blast, so as to create conditions for the adjustment of furnace conditions. The long-term stability of furnace conditions can maximize the potential of high efficiency and low consumption of the blast furnace.

2. Design furnace type of blast furnace

Since the No. 5 blast furnace (3200m3) was constructed and put into operation by introducing international technology in 1991, the ironmaking plant of WISCO began to enter the production mode of large blast furnace. In the 21st century, it has gradually changed from the introduction and absorption to the independent innovation stage. No. 6, 7 and 8 blast furnaces have been built and put into operation successively. The furnace capacity has been expanded from 3000m3 to 4000m3, and the height diameter ratio has been reduced from 2.186 of No. 5 blast furnace, 2.216 of No. 6 and No. 7 blast furnace to 2.1 of No. 8 blast furnace. The blast furnace has developed to a short and fat type in the design of furnace type. At present, among the domestic large blast furnaces, Baosteel's No. 3 blast furnace (4850m3) is a typical representative of the dwarf blast furnace, and the height diameter ratio has been reduced to 1.951. No. 8 blast furnace of WISCO has absorbed the experience of No. 6 and No. 7 blast furnaces. Copper cooling staves are used in 8 and 9 sections at the lower part of the furnace stack, 7 sections at the waist, 6 sections at the bosh and high heat load area at the hearth, which increases the cooling and heat transfer in the high heat load area and reduces the damage of the cooling staves in this area. The more wear-resistant double-layer nodular cast iron cooling staves with inlaid bricks are used in the upper 10 and 11 sections of the furnace shaft to replace the cast steel cooling staves, which improves the wear resistance of the cooling staves. Two layers of ceramic cup bottoms are laid on the top of the furnace bottom carbon bricks, which effectively reduces the direct erosion of molten iron on the furnace bottom carbon bricks. Water cooling pipes are laid below the carbon bricks, which increases the cooling and heat transfer of the furnace bottom and greatly extends the service life of the furnace bottom.

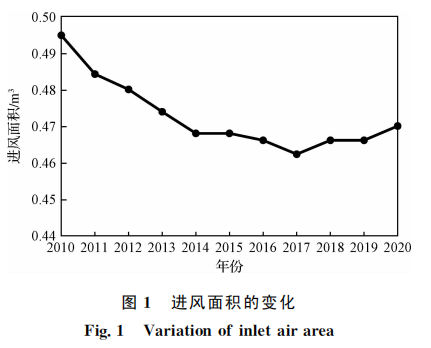

3. Change of air inlet area

As shown in Figure 1, from 2009 to 2012, the air inlet area of No. 8 blast furnace gradually decreased from 0.4948m2 (8 tuyeres with a diameter of 140mm + 28 tuyeres with a diameter of 130mm) to 0.4800m2. At this stage, "large air inlet area and large air volume" are the main factors, and the average air volume is between 7350 ~ 7600m3 / min. Due to the good quality of raw fuel, light load, large coke distribution in coke layer and good overall material column permeability, the blast furnace system is mainly c987651-332222.5+ol98765-44322+os98-31. In terms of air flow adjustment, the edge air flow is adjusted by the ore distribution at the angle of No. 10, No. 9 and No. 8. The center coke is adjusted between 2 and 3 rings. The overall air flow adjustment is mainly "to properly suppress the center and edge air flows".

From 2013 to 2017, with the brutal competition of excess capacity in the iron and steel industry, many enterprises had to reduce their procurement costs to ease the pressure on survival. The quality of raw fuels declined, the iron ore grade declined, the blast furnace slag ratio increased, the air volume was unstable, and the furnace condition was prone to fluctuations. In order to improve the blast furnace's ability to resist the change of raw fuel, the blast furnace has "appropriately developed the edge air flow on the basis of opening up the center", the air inlet area has been gradually reduced from 0.4800m2 to 0.4661m2, and the diameter has been cancelled φ 140mm air outlet to φ 130mm+ φ 120mm tuyere is mainly used to increase the blast wind speed and blast kinetic energy, activate the hearth and improve the distribution of initial gas flow. In terms of the distribution system, the central coke is adjusted between 3 ~ 4 rings. In terms of the system os987-221, the ore distribution at the edge is appropriately reduced to ensure that the central air flow is developed without excessive suppression of the edge air flow, so as to achieve the balanced development of the two air flows. After adjustment, as shown in Figure 2, although the air volume is decreasing year by year from the annual average air volume of 7442m3/min in 2013 to only 7017m3/min in 2017, the furnace condition fluctuation of the blast furnace is controlled, and the annual output can still reach more than 3.5 million tons.

From 2018 to 2020, the iron and steel industry has warmed up, the quality of raw fuels has improved, and the blast furnace inlet area has continued to be 0.4661m22, which was expanded to 0.4700m2 in September. The adjustment of blast furnace mainly focuses on "reducing the fluctuation of furnace conditions, reducing fuel ratio and reducing pig iron cost". In order to reduce fuel consumption, there have been some differences on the consumption of central coke. The central uses 2 ring coke for a period of time. In the early stage of adjustment, the utilization of gas has been greatly increased and the fuel ratio has decreased. However, with the instability of raw fuel quality, the temperature of blast furnace and the basicity of slag fluctuate. Because "both central and peripheral gas flows do not develop", As a result, the ability to resist fluctuations is insufficient, and the furnace condition fluctuates frequently. In the later stage, decisively increase the central coke amount by 4 ~ 5 rings, and appropriately reduce the distribution angle of large burning, so as to suppress the central air flow and prevent central over blowing. The small firing and large firing are distributed at different angles, and the small firing angle is appropriately moved outward, so as to suppress the edge air flow and maintain the appropriate "funnel-shaped" material layer structure. In terms of operation, the ability of the blast furnace to resist external fluctuations is significantly improved, and the overall furnace condition is more stable. In particular, in 2019, the blast furnace will achieve another good performance when it has been put into operation for 10 years, with an annual output of 3.6 million tons and an annual iron output of 3.621 million tons.

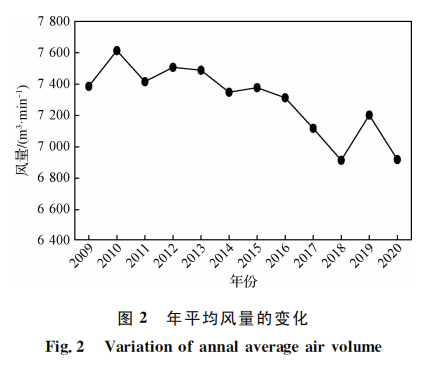

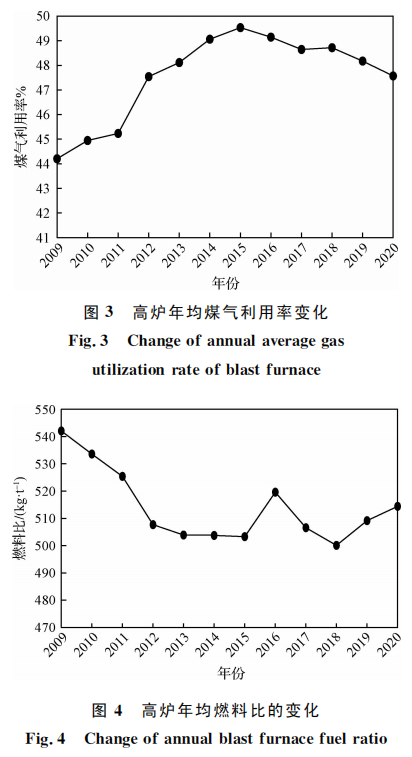

4. Control of gas utilization rate

Reasonable gas distribution is to control the development of two gas streams by adopting appropriate air supply system and charging method, so as to achieve the best utilization of gas and the lowest fuel consumption on the basis of running smoothly. In daily operation, high gas utilization helps to reduce fuel consumption. At present, there is still a gap between WISCO and Baosteel in the control of gas utilization rate. Baosteel's annual gas utilization rate is not less than 50%, while WISCO's annual gas utilization rate is only maintained at about 48%. The main reason is that there is a gap in the stability of raw material quality. The control of high gas utilization requires the material column to maintain good air permeability. If the raw material cannot be guaranteed, the stability of furnace conditions cannot be guaranteed if the high gas utilization is pursued unilaterally.

Fig. 3 shows the change of gas utilization rate of No. 8 blast furnace in the 11 years since it was put into operation. It can be seen from Fig. 3 that before 2012, due to the large consumption of large particle coke, the operation mode of "large air inlet area and large air volume" of the blast furnace, and the good air permeability of the overall material column, the gas utilization rate was not high. The average annual gas utilization rate was below 46%, the fuel consumption was high, and the fuel ratio was above 525kg/t. After August, 2011, under the mode of mixed charging of small coke in the original ore, the blast furnace increased the amount of recycled coke (1 ~ 2t) with a particle size smaller than that of coke. On the one hand, it reduced the consumption of large coke, relatively diluted the coke layer, indirectly inhibited the throughput of the coke window layer of the gas flow, prolonged the residence time of the gas flow in the furnace, and improved the utilization of gas; On the other hand, the recycled coke mixed with small particles in the ore improves the permeability of the soft melt layer of the ore, improves the secondary distribution of the gas flow, and makes the gas distribution more uniform. After 2013, the utilization of gas has increased significantly, with an average annual utilization of more than 48%. As shown in Figure 4, with the increase of gas utilization rate, the fuel consumption of blast furnace also shows a downward trend, and the annual average fuel ratio is below 510kg/t. Among them, the fuel ratio increased in 2016, which is mainly due to the overhaul of hot blast furnace, the air temperature can not be guaranteed, and the blast furnace is forced to reduce the load.

5. Fluctuation of furnace condition

On the one hand, the smooth operation of the blast furnace needs the good guarantee of the equipment, on the other hand, it needs the careful operation of the technicians to reduce the fluctuation of the furnace condition and the occurrence of abnormal furnace conditions such as pipes, suspended materials and furnace cooling, especially to avoid the occurrence of slag filling at the tuyere and burning through of the tuyere air duct. The judgment of furnace condition should be "found and handled early" to avoid the deterioration of furnace condition as far as possible. Figure 5 shows the 11 year shutdown rate of No. 8 blast furnace. With the increase of furnace life, the blast furnace equipment is aging, the exposed problems are increasing, and the shutdown rate is on the rise. In 2016, the hot blast furnace was overhauled, and the chute fault occurred in May and June 2018. The shutdown rate of the blast furnace reached more than 3.0%. In 2020, due to the damage and development of the copper cooling stave at the seventh section of the furnace waist, the blast furnace was shut down for several times to treat the water pipe, and the shutdown rate reached 4.08%. The rise of wind break rate is bound to cause a sharp decline in output. As shown in Figure 6, the annual output in 2016, 2018 and 2020 is obviously at a low point. For the later period of furnace service, it is necessary to strengthen the daily spot inspection of equipment, close loop of daily hidden danger rectification, and timely update the equipment, so as to reduce the equipment failure rate and create conditions for the smooth operation of furnace conditions in the later period. At the same time, the cooling staves at the later stage of furnace service shall be monitored, and the abnormal water replenishment shall be checked in time. The damaged cooling staves shall be grouted and equipped with coolers to ensure that the furnace shell temperature is safe and controllable.

As copper cooling staves are used in 7 sections of No. 8 blast furnace, the heat transfer effect of the cooling staves is good, and the furnace body is very easy to form slag crusts. Especially in winter, when the external temperature is low, the raw fuel performance changes, and the furnace temperature and slag alkalinity fluctuate, it is very easy to cause excessive development of slag crusts on the furnace wall, and even deteriorate the stubborn adhesion and damage the operation furnace type. Since the opening of No. 8 blast furnace, the problem of furnace condition fluctuation caused by easy adhesion in winter has always existed. As No. 8 blast furnace adopts the soft water closed circulating cooling system, the cooling intensity of the blast furnace cannot be controlled separately section by section. The operator only controls the cooling intensity by adjusting the soft water flow and inlet water temperature, and the adjustment measures are limited. At the same time, due to the shortage of raw materials and fuels and the decline of quality in winter, the blast furnace operation is often not timely, blindly pursuing high production and low consumption, which is bound to cause its own furnace condition fluctuations.

In the past 11 years, there was no adhesion in 4 of them. The reasons were summarized and analyzed:

(1) The upper and lower parts of the blast furnace are adjusted by "taking the wind as the key link". As for the air inlet area of the tuyere, the air inlet area shall be appropriately reduced in the early stage of furnace service to ensure large blast wind speed and blast kinetic energy, ensure the activity of the hearth, promote the coke replacement in the central dead coke area, ensure smooth air flow, and create conditions for the adjustment of furnace conditions. At the later stage of furnace service, the air inlet area can be appropriately expanded to maintain sufficient air volume, assist with appropriate central coking, and maintain the dynamic balance of "appropriate development of central air flow and appropriate suppression of edge air flow".

(2) Especially when the temperature is low in winter, do not excessively pursue low consumption. The furnace temperature and physical heat should be controlled at the upper limit, with the mass fraction of Si not less than 0.4% and the physical heat not less than 1500 ℃. Maintain the lower limit control of the binary basicity of the slag of 1.18 ~ 1.25. When the slag r>1.25, it should be adjusted in time to reduce the sintering consumption. If necessary, Hainan ore should be directly used to replace part of the sinter or lump ore consumption to avoid long-term high basicity slag system, Cause poor fluidity and induce furnace body adhesion.

(3) The molten iron and slag shall be discharged evenly in front of the furnace. For the late arrival of slag and short slag discharge time, the oxygen control intensity shall be controlled to prevent furnace suffocation, and the differential pressure operation shall be controlled in time to reduce the fluctuation of furnace conditions.

(4) For the problem of furnace body adhesion, it is necessary to "find out and deal with it early". When the furnace body temperature and water temperature difference drop, the system of loose edges should be adopted in time. Os98-22 should be adjusted to os987-122, ol98765-44322 to ol98765-33322 or ol98765-23322, so as to try to reverse the situation in the early stage.

6. Hearth status of blast furnace

The hearth condition of blast furnace is the key to the longevity of blast furnace. A good hearth condition can ensure that the hearth is active, the initial gas flow distribution is reasonable, and the erosion of slag and iron flow is small. The depth of dead iron layer of No. 8 blast furnace of WISCO is 2.8m and the diameter of hearth is 13.6m. The working state of hearth is monitored by bottom thermometer. During daily operation, pay attention to the temperature change of furnace bottom and hearth side wall. Each shift is responsible for measuring the inlet and outlet water temperature difference of furnace bottom water cooling pipe and hearth cooling wall, and the optimal cooling water temperature difference of hearth Δ TG ≤ 0.65 ℃, heat flow strength QG is (2300 ~ 3500) × 4.18kJ/(m2·h)。 Optimum temperature difference of cooling water at furnace bottom Δ T ≤ 0.85 ℃, QG is (1450 ~ 2200) × 4.18kj/ (M2 · h), the inlet temperature of soft water shall be controlled at 36 ~ 42 ℃, and the temperature difference of cooling wall water shall not be greater than 6.0 ℃.

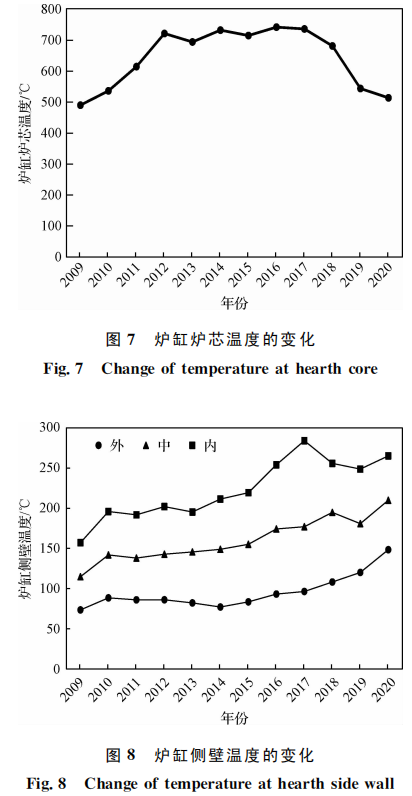

At present, the measured value of hearth water temperature difference is 0.2 ~ 0.4 ℃, the temperature difference of furnace bottom water is within 0.6 ℃, and the heat load is within the best control range. Figure 7 shows the temperature change of furnace core (bottom temperature of 2-layer ceramic cup) in 11 years of operation. It can be seen from the figure that the furnace core temperature continues to rise at the initial stage of production, and the furnace core temperature is basically above 500 ℃ in the 11 years of production. The continuous high furnace core temperature is conducive to the replacement of the central dead coke column, creating conditions for the coke layer to maintain good air permeability and liquid permeability. Figure 8 shows the change of hearth side wall temperature in 11 years. It can be seen from the figure that with the increase of furnace age, the temperature at the outer, middle and inner temperature points of the side wall continues to rise, indicating that the overall temperature control of the hearth is good and the hearth activity remains good. At present, the high point of the inner wall temperature is mainly below the three tapholes, so the temperature monitoring in this area should be strengthened.

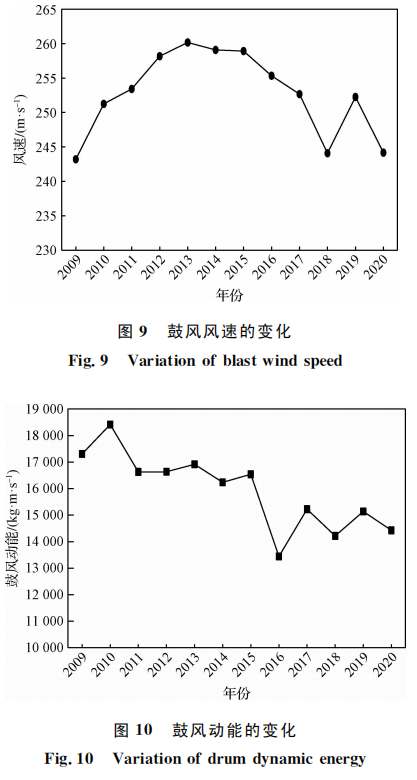

Proper wind speed and blast kinetic energy can help maintain a certain raceway length, enhance the penetration of blast to the center of hearth, strengthen the continuous and efficient replacement reaction between coke and center coke in the combustion zone at the front of tuyere, reduce the dead column area of hearth, increase the circulation area of slag and iron flow, and maintain the activity of hearth. Fig. 9 and FIG. 10 respectively show the changes of annual average blast wind speed and blast kinetic energy of No. 8 blast furnace in the 11 years of operation. In the early stage of furnace campaign, the blast furnace was operated with large air volume, and the blast velocity (more than 250m/s) and blast kinetic energy (more than 15000kg · m/s) of the blast furnace were maintained at a high level. After 2016, due to equipment failure and furnace condition fluctuation, the number of fluctuations in the furnace condition of the blast furnace was increased, resulting in insufficient blast velocity and blast kinetic energy of the blast furnace. In the middle and later stages of furnace service, the stable and smooth operation of furnace conditions is still the main thing to maintain continuous production and reduce the abnormal shutdown of hearth "engine".

In the control of blast furnace slag and iron discharging process, it is necessary to ensure that the slag and iron in the hearth are discharged in time and evenly, so as to reduce the occurrence of furnace holding. In the process of iron tapping, the iron content difference shall be calculated in time and controlled within 10%. When the slag iron flow is uneven, the oxygen control intensity shall be controlled in time to reduce the tapping interval and the storage of slag iron flow in the hearth per unit time, so as to effectively reduce the scouring of slag iron annular flow on the hearth area and create conditions for the longevity of the hearth.

7. Conclusion

(1) No. 8 blast furnace has been put into operation for 11 years, and the lower part has been adjusted to gradually reduce the air inlet area, ensuring sufficient blast kinetic energy and tuyere raceway of the blast furnace, creating conditions for maintaining the activity of the hearth. The upper adjustment mainly focuses on central coking and assists in fine adjustment of ore distribution system to maintain the dynamic balance of "appropriate development of central air flow and appropriate suppression of edge air flow" of the two gas flows. Taking wind as the key link, it ensures the long-term stability of the blast furnace.

(2) In view of the phenomenon that the furnace body is easy to stick in winter, it is necessary to strengthen the response measures to the changes of raw materials and fuels, control the upper limit of molten iron temperature and the lower limit of alkalinity, ensure that the slag iron is cleaned in time, loosen the edge in time in the early stage of bonding, maintain large air volume operation, properly sacrifice some fuel consumption, and timely reverse the deterioration of furnace body sticking.

(3) After 11 years of operation of No. 8 blast furnace, the hearth and bottom are still in good condition. It is important to strengthen the temperature monitoring of hearth side wall. During the operation, try to maintain the long-term stability of the air volume, reduce the fluctuation of the furnace condition, ensure the activity of the hearth, and timely organize the discharge of slag and iron in the hearth to reduce the scouring of the slag and iron circulation on the hearth, so as to create conditions for the long-life continuation of the blast furnace.