15358968703

Practice of hot pressing treatment technology for residual heat from rolling crushing of steel slag

Abstract: China has a large amount of steel slag, and the environmental protection requirements are becoming increasingly strict. The cleaning treatment and resource utilization of steel slag are becoming increasingly urgent. This paper introduces the process route and supporting special equipment of the steel slag rolling crushing waste heat pressurized hot stuffy technology, and carries out the pilot test of the power generation with the pressure hot stuffy steam waste heat, explores the process of the steel slag waste heat utilization, and realizes the breakthrough of the steel slag waste heat recovery. With high automation level and good steel slag treatment effect, the steel slag rolling crushing waste heat pressurized hot pressing technology is a new type of green and environmental friendly modern compact process slag treatment method, which has the characteristics of cleaning, equipping, recycling, no falling of steel slag, small floor area, etc. it promotes the steel slag treatment from engineering mechanical operation to equipping and automatic operation, providing conditions for the environmental protection treatment of steel slag, and should be vigorously promoted and applied.

Key words: steel slag; Resource utilization; Heat tightness

1. Foreword

Steel slag is a solid waste produced in the associated steelmaking process, and about 12~15% of steel slag is produced per ton of smelting. In 2018, the total output of steel slag in China was about 120 million tons, and the output of steel slag was very huge. Steel slag is mainly composed of calcium silicate minerals, metallic iron and iron oxides. Calcium silicate minerals and other components are mainly composed of dicalcium silicate (2CaO · SiO2), tricalcium silicate (3CaO · SiO2), olivine (Cao · ro · SiO2), rose pyroxene (3CaO · ro · 2SiO2) and RO phase (solid solution of MgO, MnO and FeO).

At present, steel slag is mainly used as building materials and road materials. However, because steel slag contains a certain amount of free calcium magnesium oxide, which expands when meeting with water, the safety of steel slag as building materials is brought about, resulting in a large number of steel slag can not be effectively used. In 2019, the actual utilization rate of steel slag in China is less than 30%. Steel slag resources are wasted, occupy a lot of land, and may pollute the environment. Therefore, reasonable treatment methods and digestion approaches are urgently needed. In recent years, China's environmental emission standards have been increasingly improved. The resource utilization of steel slag and the improvement of environmental emission requirements have put forward higher requirements for the treatment and utilization technology of steel slag. This paper expounds the development of steel slag treatment technology, introduces in detail the technology and development process of steel slag roller crushing waste heat pressurized hot sealing, and expounds the application practice of steel slag roller crushing waste heat pressurized hot sealing.

2. Principle and technical development of steel slag hot sealing

2.1 hot sealing principle of steel slag

A large amount of lime is added in the steelmaking process. Due to the short slagging time, the excess Cao and MgO have not been completely melted and are wrapped in the steel slag in a free state. The steel slag heat sealing treatment is to use the steel slag waste heat in the closed container to draw water from the hot steel slag to produce supersaturated steam, so as to promote the rapid reaction and digestion of f-CaO and steam in the steel slag. Complex physical and chemical actions occur in the process of heat sealing. The specific characteristics are as follows:

(1) The steel slag is cracked by quenching. The high-temperature steel slag encounters a large amount of water to produce a sharp temperature drop. During the rapid cooling process of the slag, various minerals undergo violent phase transformation, resulting in stress and cracking of the steel slag.

(2) Steaming action. High temperature slag reacts with the hot stuffy water to produce a large amount of the supersaturated steam with the a certain pressure and a temperature above 105 ℃. This environment promotes the diffusion and penetration of water vapor into the crack of broken steel slag, which is conducive to the f-CaO digestion reaction.

(3) Crystal form transformation of dicalcium silicate (C2S). During the cooling process of steel slag from 750 ℃ to 650 ℃, dicalcium silicate (C2S) is composed of β- C2S to γ- C2S, volume expansion 10%, steel slag continues to break.

(4) Under the closed condition of steel slag and supersaturated steam, f-CaO reacts with water to form Ca (OH) 2, with volume expansion of 98%, and f-mgo reacts with water to form Mg (OH) 2, with volume expansion of 98%.

The steel slag is crushed and powdered based on the above physical and chemical effects, which eliminates the instability of steel slag and promotes the separation of slag and iron. The main reaction of steel slag during hot pressing is the reaction of free calcium oxide and free magnesium oxide. F-CaO in steel slag is dense due to overburning, with poor activity and slow hydration reaction at room temperature. It often takes several years to completely digest under natural conditions. The higher the concentration of water vapor, the higher the pressure, the better the digestion reaction of f-CaO, and the higher the temperature, the faster the reaction rate.

2.2 development of steel slag hot sealing technology

In order to solve the problems of rapid crushing and stability of steel slag, MCC Construction Research Institute and relevant units successfully researched the first generation of steel slag heat sealing treatment technology in 1992, which is to pour the steel slag into the heat sealing device after it is cooled to about 400 ℃ on the ground, and then shovel and dump it into the heat sealing device. The cover is sealed and sprayed with steam to generate water, which cracks and pulverizes due to physical, mechanical and chemical reactions with the steel slag. However, there are some disadvantages such as environmental pollution caused by steel slag hot splashing, large floor area, long treatment time and so on.

In 2004, the second generation of steel slag heat treatment technology was successfully developed. In order to shorten the treatment cycle of steel slag, the liquid steel slag is splashed to the ground. When it is cooled to 800 ℃, the steel slag is transported to the hot sealing device with a forklift or grab and tipped over, and then the cover is covered to seal and spray water for hot sealing. The lining steel plate of the first generation of heat sealing device is easy to deform at 800 ℃, and the second generation process uses heat-resistant cast iron plate as the lining. The existing problems are that the problems of environmental pollution and large land occupation caused by hot splashing of steel slag have not been completely solved, and the problem of 800 ℃ steel slag damaging the grasping and transporting equipment.

In 2008, the third generation of molten steel slag heat sealing treatment technology was successful. The steel slag at about 1650 ℃ was directly dumped into the heat sealing device, sprayed with water to solidify its surface, and then covered with the device cover to spray water intermittently until the steel slag temperature dropped to about 65 ℃. This technology has basically solved the previous problems of land occupation and environmental emission, but there are still problems of insufficient equipment automation level and long heating and cooling cycle.

In 2012, we successfully developed the fourth generation of steel slag heat sealing treatment technology, i.e. the new technology of molten steel slag rolling crushing and waste heat pressurized heat sealing. After the laboratory simulation experiment and pilot test, the demonstration production line was finally built in Henan Jiyuan Iron and steel (Group) Co., Ltd., which realized the industrial production and made great progress in the hot sealing technical equipment and automation level.

3. New technology of steel slag rolling crushing and hot pressing with waste heat

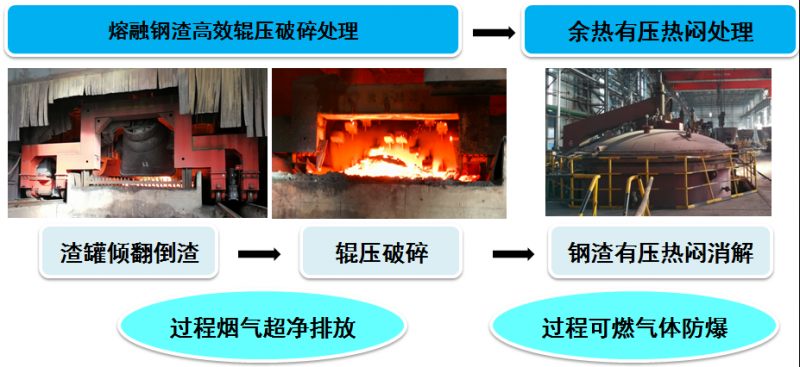

Centering on the pressurized hot pressing process, MCC Construction Research Institute has developed systematic process equipment technology, of which the core equipment mainly includes steel slag roller crushing device and pressurized hot pressing tank, as shown in Figure 1.

Fig. 1 main equipment of steel slag hot pressing

The high-efficiency tank type pressurized hot pressing treatment technology for molten steel slag can be roughly divided into two stages: steel slag rolling crushing and waste heat pressurized hot pressing. The rolling crushing stage is mainly to complete the rapid cooling and crushing of molten steel slag. The treatment time in this stage is about 30min. After the treatment in this stage, the temperature of molten steel slag can be cooled from about 1600 ℃ to about 600 ℃, and the particle size can be crushed to less than 300mm. The residual heat pressurized and hot stuffy stage is mainly to complete the stabilization treatment of steel slag after rolling crushing. The treatment time in this stage is 1.5-3h. The steel slag after treatment is stable, with free calcium oxide content less than 2.5% and soaking expansion rate less than 1.5%.

The key process equipment independently researched and developed for the steel slag waste heat pressurized hot pressing technology mainly includes: slag tank tipper, roller crusher, slag tank transfer trolley and steel slag pressurized hot pressing device. This new steel slag treatment process, compared with the currently widely used steel slag pool type hot pressing process, meets the requirements of modern steel slag treatment for high efficiency, equipping, safety and cleaning production, makes the steel slag treatment process more clean and efficient, and improves the shortcomings of the existing steel slag stabilization process, such as poor operating environment, high labor intensity and long treatment cycle.

Compared with the existing atmospheric tank type hot pressing technology, the steel slag rolling crushing waste heat pressurized hot pressing technology has the following unique advantages:

(1) The heat sealing cycle is short, about 2h, and the treatment efficiency is high, which is 7-10h shorter than the ordinary existing atmospheric tank heat sealing process;

(2) High automation level and small number of staff;

(3) The treatment process has a high degree of cleanliness and purification, a good working environment and a high level of environmental protection;

(4) After hot pressing, the steel slag has high pulverization rate, the content of steel slag with particle size less than 20mm is more than 70%, and the soaking expansion rate is less than 2%, with good stability;

(5) The emission concentration of flue gas in the production process of steel slag treatment is less than 10mg/nm3, meeting the ultra clean emission requirements.

(6) The construction cost and operation cost are low, and the operation cost can be saved by 40%.

The pressurized hot closed tank treatment is carried out in a fully enclosed state, which is cleaner and more environmentally friendly than the previous steel slag treatment technology; In addition, a large amount of steam is generated in the closed tank during the pressurized hot closed tank treatment, which is expected to be integrated for power generation, creating conditions for the recovery and utilization of sensible heat of steel slag.

4. Exploration and test of power generation with pressurized hot and stuffy waste heat

With the support of the special fund for technology development and research of the Environmental Protection Institute of the Ministry of science and technology, research has been carried out on the steel slag waste heat recovery technology since 2012. The pressurized hot sealing process provides continuous, pressurized and controllable high-temperature steam for steel slag waste heat recovery and power generation, and has the material conditions for power generation and recovery of steel slag waste heat.

Since 2015, the project R & D team has carried out preparations for the pilot test of pressurized hot air power generation in Cangzhou railway, and completed the construction of the pilot test line in early 2016. The heat source for power generation comes from the pressurized steam generated by the hot sealing reaction tank in the steel slag treatment workshop of Cangzhou China Railway iron and steel company. The steam pipeline is connected from two hot sealing tanks and sent to the steam water heat exchanger through the main steam pipeline for heat exchange.

The temperature of steel slag waste heat pressurized hot steam is 120 ℃, and the pressure is 0.2-0.4mpa. The pressurized hot steam is used to heat the closed circulating water in the heat exchanger. The heated circulating water then heats the working medium for power generation, and finally drives the generator to generate power through the working medium. Figure 2 shows the pilot test site of pressurized hot and humid waste heat power generation.

Fig. 2 pilot test site of steel slag pressurized hot and humid waste heat power generation

In 2016, the pilot test results of power generation with steel slag pressurized hot mugging waste heat show that the test line operates stably and reliably, and can generate power by integrating pressurized hot mugging steam; It is expected to achieve 3~5kwh per ton of steel slag power generation through steel slag waste heat power generation in this way. In the future, more large-scale power generation industrial tests can be carried out to realize the recovery and utilization of steel slag waste heat.

5. Industrial production promotion and Application

After a series of systematic research and industrial optimization design, the steel slag roller crushing waste heat pressurized heat treatment technology has been successfully applied to 26 iron and steel enterprises such as Shougang Jingtang Iron and Steel Co., Ltd. and Jiangsu Binxin iron and Steel Co., Ltd. in China, and exported to Malaysia United Steel Group along the "the Belt and Road". A total of 54 sets of steel slag treatment production lines have been built, with a contract amount of 2.354 billion yuan.

In October, 2012, Henan Jiyuan steel plant completed the first set of industrialization demonstration, promotion and application project. It has been put into operation for more than 8 years. The production experience shows that the steel slag treatment effect with this technology is good. After treatment, the -20mm particle size in the steel slag exceeds 75%, the content of free calcium oxide is less than 2.5%, the soaking expansion rate is less than 1.5%, and the metal iron in the tailings is less than 1.5%.

Figure 3 site of 600000 T / a steel slag treatment production line of Henan Jiyuan Iron and steel

In 2017, the 700000 T / a steel slag hot pressing treatment and processing and purification production line project of Jiangsu Binxin iron and Steel Group, which was EPC contracted by MCC energy conservation and environmental protection Co., Ltd., was successfully loaded at one time and put into operation successfully. The vertical hot pressing technology of steel slag was adopted for the first time in this project. The steel slag vertical pressurized hot pressing technology is based on the horizontal pressurized hot pressing technology of MCC energy conservation and environmental protection Co., Ltd. to re optimize the process flow, cancel the processes such as the operation of slag loading vehicle and track connection, and mostly shorten the original process flow. The technology has been directly applied in the actual process without any industrial test, and the operation effect has been recognized and praised by the owner.

In May, 2019, Shougang Jingtang Iron & Steel Co., Ltd. officially put into operation a steel slag treatment production line with a design capacity of 600000 tons / year. The operation of the system equipment is stable and reliable, and the steel slag treatment effect is good. The project implements the wet electrostatic precipitator wet dust removal technology for the flue gas treatment in the steel slag production process, and the flue gas emission concentration in the steel slag treatment process is stable to <10mg/nm ³ Ultra low emission effect. The project is the first time that the technology and equipment have been successfully applied to domestic first-class iron and steel enterprises, effectively promoting the development of domestic steel slag .

Figure 4 site of Jingtang 600000 T / a steel slag treatment production line of Shougang

The design capacity of the steel slag treatment production line of United Steel (Malaysia) group is 500000 T / A. The production line was officially put into operation in June 2018 and has been put into operation for more than 2 years. The operation of the system equipment is stable and reliable, and the steel slag treatment effect is good. The project implements the wet electrostatic precipitator wet dust removal technology for the flue gas treatment in the steel slag production process, and the flue gas emission concentration in the steel slag treatment process is stable to <10mg/nm ³ Ultra low emission effect. The project is the successful export of this technology and equipment to Malaysia along the "the Belt and Road", which has established a typical demonstration for the international market application of steel slag treatment technology.

6. Conclusion

In recent years, with the rapid development of China's industry, environmental problems have become increasingly serious, and the resource utilization of steel slag has become increasingly urgent. The steel slag pretreatment technology represented by the steel slag rolling crushing - residual heat pressurized hot pressing technology has a higher level of equipment and automation, which can realize the efficient and continuous production of steel slag treatment. The steel slag treatment effect is good, the system equipment occupies less land, and the supporting civil engineering and public auxiliary investment is low. The new technology has more significant technical advantages and competitive price advantages in steel slag treatment. In addition, the application process of this technology is more environmentally friendly, which can meet China's increasing environmental emission standards and meet the needs of equipment automation. It is a reliable choice for the application of steel slag treatment technology in the future. At present, more than 50% of domestic steel slag treatment still adopts the backward hot pouring production process. Under the current situation, iron and steel enterprises should improve the technical level and equipment level of steel slag treatment to meet the increasingly stringent environmental protection requirements. Speed up the elimination of backward treatment methods such as steel slag hot splashing, vigorously promote the technology of steel slag roller crushing waste heat pressurized hot sealing, and realize the clean, efficient and equipment treatment of steel slag as soon as possible.