15358968703

MCC CCID equipment won the bid for the standby project of Baowu Kunming section steel short stress line universal mill

Good news of winning the bid

On June 16, CCID equipment received a formal notice from the European metallurgical platform and successfully won the bid for the supply of spare machines for the short stress line universal mill of the new section steel production line of Kunming Iron and Steel Co., Ltd. of China Baowu group.

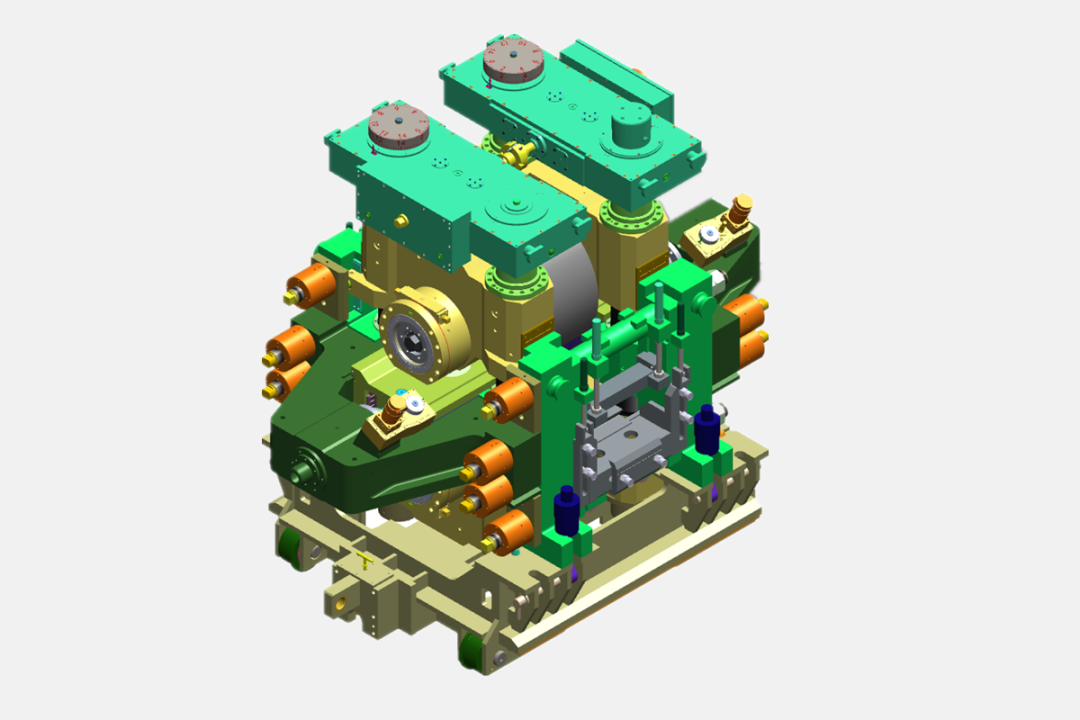

Fig. 1 MCC CCID short stress line universal mill

The section steel production line of Kunming Iron and Steel Co., Ltd. was completed and put into operation in 2012, with an annual output of 800000 tons. It mainly produces H-section steel, I-beam, channel steel, angle steel and other products. The maximum specification of H-section steel is 400 × 200mm, adopting the semi continuous rolling process of 1 bloom +10 continuous rolling, it is the main production line of small and medium-sized H-beam in Southwest China.

According to the specific production and use of the rolling mill of the production line, CCID equipment upgrades the short stress line universal rolling mill based on the design concept of high rigidity, high precision and high stability, so as to realize the iterative upgrading of the rolling mill. The successful bid winning of this project is the first application of MCC CCID's nhum series short stress line universal mill. It marks that MCC CCID has achieved comprehensive independent control over the core equipment in the field of universal section steel, such as bloom rolling mill, arch universal mill, short stress line universal mill and section steel straightener. It is of great significance to further enhance the competitiveness of the company in the key process equipment technology of universal section steel.