15358968703

Numerical calculation and process optimization of solidification heat transfer in slab continuous casting process

Abstract: the solidification heat transfer law of slab in continuous casting process is closely related to slab quality and continuous casting process. The numerical calculation study on the solidification heat transfer process of continuous casting slab in a plant shows that there is an obvious warming trend at the beginning of secondary cooling zone 6 ~ 8 and air cooling zone, and the billet shell temperature is higher, and the temperature at the center of the wide surface of the slab at the end of zone 8 reaches about 1032 ℃. In addition, the solidification end point calculated by the heat tracking model of the soft reduction system is relatively forward, and the reduction interval needs to be optimized. In view of the above problems, the amount of secondary cooling water is increased from 0.42 l/kg to 0.56 l/kg, and the center solid rate of slab in dynamic soft reduction section fs=0.3~0.7 is optimized to fs=0.5~1.0. After the process optimization, the cracks in the slab are improved, and the central carbon segregation index is reduced from 1.23 to 1.09.

Keywords continuous casting; Slab; Solidification heat transfer; Gently press down; Internal crack; Central segregation

1. Introduction

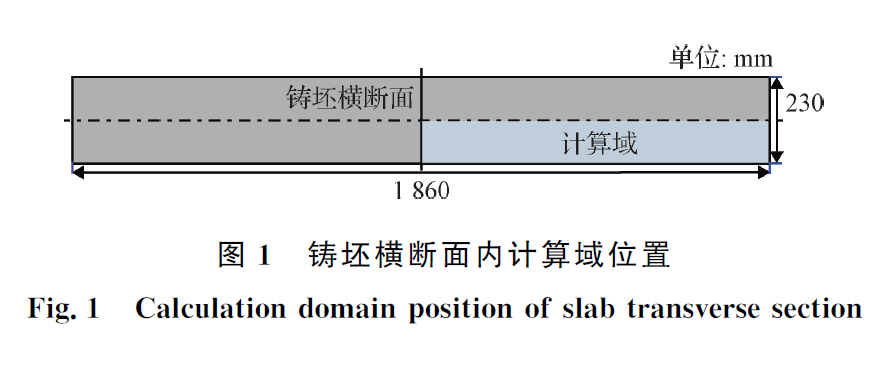

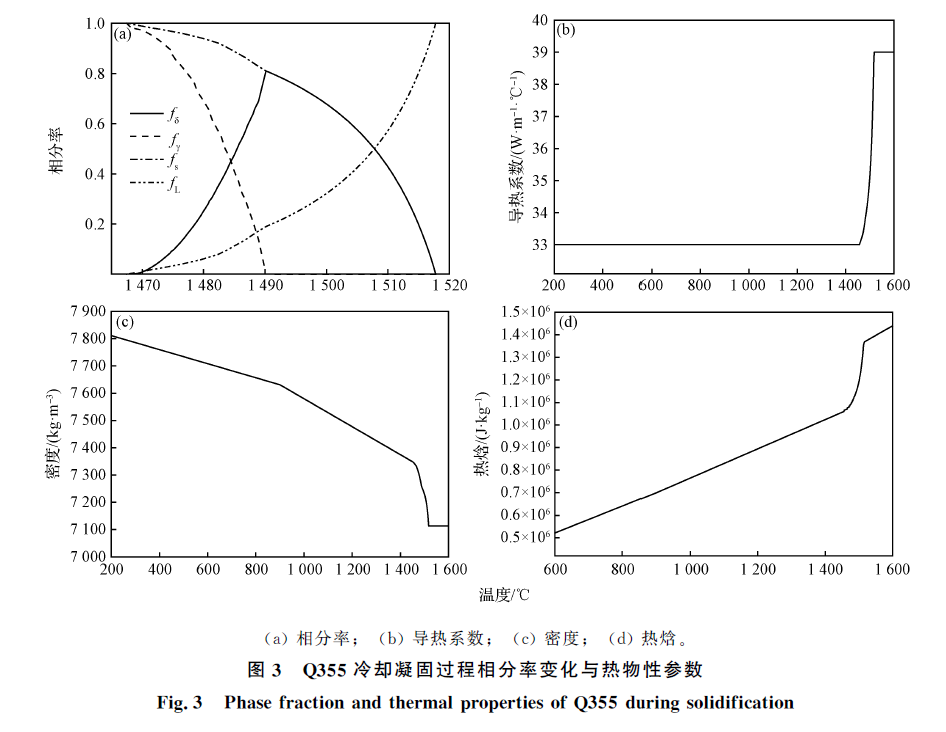

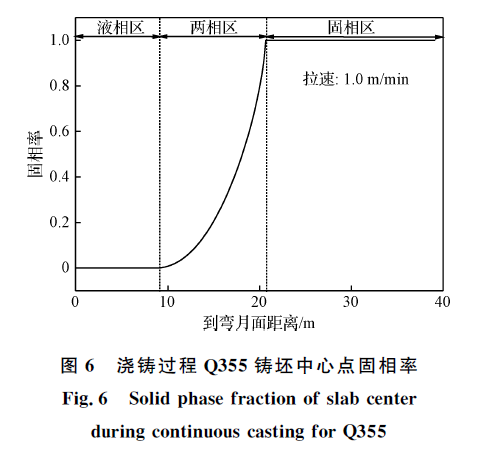

Continuous casting is an important process in the current steel production process, which has the advantages of high metal yield and high efficiency. At present, more than 96% of crude steel production adopts continuous casting. In the process of continuous casting, the heat released by the slab after mold cooling, secondary cooling and air cooling before the end of the caster reaches more than 40% of the total heat, which directly affects the surface quality (surface crack), internal quality (internal crack, central segregation) and the smooth operation of the continuous casting process. In addition, the solidification heat transfer law of continuous casting slab is closely related to soft reduction and other processes, which is the key basis for formulating soft reduction interval and reduction amount. In order to formulate reasonable cooling and other related process parameters, some researchers have carried out research on the solidification heat transfer law of slab during continuous casting. Xie Zhonghao et al. Used ANSYS software to establish the calculation model of solidification heat transfer and stress of large cross-section round billet continuous casting, combined with the results of in-situ analysis and scanning electron microscope, revealed the causes of the central crack of large cross-section round billet continuous casting, and put forward control measures. Wu C H et al. Calculated the solidification heat transfer process of slab continuous casting under non-uniform cooling conditions, and calculated the theoretical reduction amount, thermal shrinkage deformation and shell bulge deformation of light reduction on this basis, which provided a theoretical basis for setting the light reduction process, caster foundation roll gap and reasonable cooling process. Pan Wenfeng et al. Calculated the solidification heat transfer law in the slab continuous casting process by using a three-dimensional model, and compared and analyzed the wide temperature distribution characteristics of the slab under different secondary cooling nozzle installation methods. Based on this, the nozzle installation method was optimized, and the wide cooling solidification uniformity of the slab was significantly improved. Based on the numerical calculation results of corner temperature of microalloyed steel billets under different cooling processes, Cai Zhaozhen and others successfully developed and applied the ultra-fine grain controlled cooling process of billet corners, which effectively solved the problem of transverse corner cracks of microalloyed steel billets. Wang Shaowei et al. Established the solidification heat transfer model of medium carbon steel slab continuous casting process, quantitatively revealed the relationship between element segregation, molten steel viscosity and central solid rate of slab, and formulated the optimal soft reduction interval. Gao Xiangzhou et al. Carried out numerical simulation on the solidification heat transfer law of wide and thick slab continuous casting process, and compared and analyzed the laws of characteristic point temperature and two-phase zone length under different casting conditions, which provided data support for the formulation of soft reduction process. In this paper, a two-dimensional solidification heat transfer model is established for the cross-section of a continuous casting slab in a plant. The slab characteristic point temperature, core solid rate and shell thickness in the continuous casting process are calculated and analyzed, and compared with the calculation results of the on-line heat tracking model of the soft reduction system. On this basis, the secondary cooling water distribution and soft reduction interval are optimized, and the industrial tests are carried out with the optimized process, The cracks and central segregation in the slab are effectively improved.

2. Selected charts

3. Conclusion

(1) The simulation calculation was carried out for the secondary cooling solidification heat transfer process of the slab under the original process conditions. It was found that the core temperature of the slab decreased slowly before the solidification end point and decreased rapidly after the solidification end point; When the casting speed is 1.0 m/min, the length of the two-phase zone is about 11.67 m, and the thickness of the shell at the outlet of the crystallizer is about 14.4 mm. With the increase of casting speed by 0.1 m/min, the length of the two-phase zone increases by about 0.92 m, and the thickness of the shell at the outlet of the crystallizer decreases by about 0.25 mm; At the beginning of secondary cooling zone 6 ~ 8 and air cooling zone, there is a large warming trend, and the overall temperature of the billet shell is high. The temperature of the wide surface center of the slab at the end of zone 8 is about 1032 ℃. (2) When the casting speed is 1.0 m/min, compared with the developed two-dimensional solidification heat transfer model, the solidification end point calculated by the online heat tracking model of the soft reduction system is about 1.4 m ahead. (3) Based on the calculation results of solidification heat transfer, the secondary cooling water distribution and dynamic soft reduction interval are optimized. The specific water volume of secondary cooling is increased from 0.42 l/kg to 0.56 l/kg, and the dynamic soft reduction interval is optimized from fs=0.3~0.7 to fs=0.5~1.0. After the process optimization, the cracks in the slab were significantly improved, and the central carbon segregation was reduced from 1.23 to 1.09.