15358968703

Research on technology of reducing consumption and improving efficiency of steel rolling heating furnace

Heating furnace is an important thermal equipment in the production process of iron and steel industry, and plays a very important role in steel rolling production. Its energy consumption accounts for 6% of the total energy consumption of iron and steel industry. The main task of the heating furnace is to heat the billet to the required temperature on the premise of ensuring the heating process requirements, reduce the consumption of gas and electric energy as far as possible, and reduce the environmental pollution caused by emissions. This paper makes an in-depth and comprehensive study on the intelligent control technology of the heating furnace, adjusts the operation state and process parameters of the heating furnace to achieve the best operation state, improves the stability and reliability of the heating furnace operation, and solves the problems of large fluctuation of billet discharge temperature, uneven section temperature, high oxidation burning loss rate, large energy consumption and serious emission pollution.

1. Factors affecting oxidation burning loss and gas consumption

During the heating process of the billet in the heating furnace, the surface of the billet is oxidized due to the presence of oxidizing gases (O2, H2O, SO2) in the furnace. Generally, the oxidation burning rate is as high as 5%-6%, which seriously affects the yield. A large number of literature studies show that furnace temperature, heating time and furnace atmosphere are the main factors affecting the oxidation and burning loss of billets.

1.1 unbalanced furnace temperature control

Because the calorific value and pressure of gas fluctuate greatly, and the system has poor inhibition ability to them, the temperature fluctuation in the furnace is serious. Too high heating temperature will cause overheating, overburning and serious oxidation of billet, affect normal rolling and even produce waste, resulting in waste of raw materials and energy. On the contrary, insufficient heating temperature will affect normal rolling and cause great wear to the rolling mill and rolling spoke. Therefore, we must understand the basic knowledge of billet heating process and formulate the correct heating process system to reduce the production defects caused by the heating process.

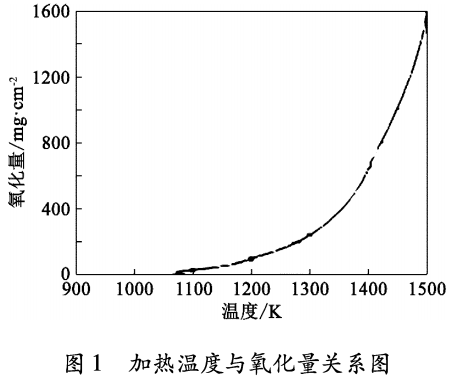

Heating temperature is the main factor of slab surface oxidation. With the increase of temperature in the heating furnace, the slab surface oxidation speed gradually accelerates. The relationship between heating temperature and oxidation amount of plain carbon steel is a parabola, as shown in Figure 1. When the temperature is lower than 1000K, the oxidation and burning loss of plain carbon steel is very small and generally negligible; When the temperature is 1000-1100k, the oxidation burning loss is small; When the temperature is 1100-1300k, the oxidation burning loss increases slowly; When the temperature is 1300-1400k, the diffusion rate of each component gradually accelerates, and the oxidation and burning loss of plain carbon steel rapidly increases; When the temperature exceeds 1400k, the iron oxide scale on the surface of plain carbon steel begins to melt, and the oxidation burning loss increases sharply. At the same time, if the temperature is too high, the consumption of gas will increase accordingly, wasting gas.

1.2 influence of heating time

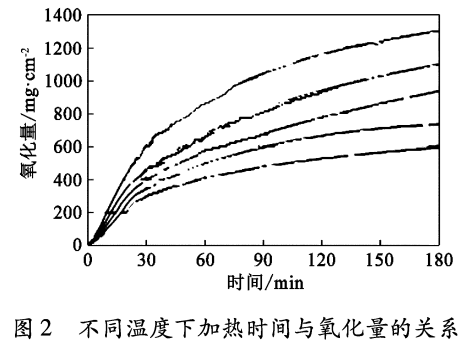

Under the same heating system, with the extension of heating time, the oxidation burning loss of slab surface gradually increases, and its weight gain changes in a parabolic law. Fig. 2 is the relation curve between heating time and oxidation amount of 1390-1470k ordinary carbon steel billet when the oxygen concentration is 3%. It can be seen from the figure that the trend of billet oxidation with time at all temperatures is roughly the same; In 0-30min, the oxidation reaction is intense, and the oxidation burning loss of carbon steel rises sharply; After 30min, the oxidation and burning loss of carbon steel gradually slowed down. At the initial stage of oxidation, the steel substrate is in direct contact with air, and the oxidation weight gain rate is fast. With the heating, the dense iron oxide scale generated covers the surface of the steel substrate, and the external oxidizing medium is not easy to penetrate, which hinders the formation of iron oxide scale. Therefore, the oxidation rate slows down, but the overall oxidation volume increases with the increase of time.

Although the temperature of each sample billet differs by 20K, the increment of oxidation amount is different. In the first 30min of heating, the increment of oxidation amount is small, but as the heating continues, the increment of oxidation amount gradually expands within 30-60min, and after 60min, the increment of oxidation amount tends to be stable. The increase of oxidation amount increases with the increase of temperature, indicating that the higher the temperature is, the greater the oxidation reaction speed is, so it is necessary to shorten the residence time of billet in the high temperature zone.

1.3 influence of atmosphere in furnace

Under normal circumstances, in order to achieve the best combustion of gas and air, the value range of air coefficient is 1.02-1.10. If the air is insufficient and the combustion is insufficient, black smoke will be generated, energy will be wasted, thermal efficiency will be reduced, and the environment will be polluted; If there is too much air, the excess air will take away heat, causing waste of gas, reducing the combustion temperature, increasing the oxidation and decarburization of steel, which will not only waste materials but also bring difficulties to phosphorus removal, seriously affect the surface quality of products, and increase the emission of NOx. Therefore, it is very important to control the reasonable air coefficient. In actual production, under the condition of ensuring a reasonable heating temperature in the soaking section, a lower air coefficient should be adopted to reduce the oxygen concentration near the high-temperature billet, so as to reduce its oxidation burning loss rate.

2. Optimization of heating furnace combustion process

2.1 billet temperature calculation model

The calculation model of billet temperature is the key to realize the optimal setting control system of furnace temperature, and the online calculation of billet temperature is the basis of furnace temperature feedback control. The deviation between the real-time calculated temperature of the billet and the set heating curve of the billet is used as the input of feedback compensation control, and the heating process of the billet is heated strictly according to the ideal heating curve.

2.2 furnace temperature setting and adjustment control based on expert rules

The feedback compensation control is used to dynamically compensate the set value of the optimal furnace temperature in each section. At the same time, the furnace temperature in each section of the heating furnace is adjusted by using expert experience according to the measured temperature of the discharged billet.

2.3 air fuel ratio self optimization algorithm

The optimal ratio of air and gas is an important part of the combustion control of heating furnace. The reasonable allocation of air-fuel ratio is conducive to reducing fuel consumption. The air-fuel ratio is too high, the furnace temperature decreases, and more fuel is needed to heat the billet, resulting in increased fuel consumption. If the air-fuel ratio is too low and the fuel cannot be completely burned, the fuel consumption will inevitably be too high. The characteristic of self seeking optimal control of air-fuel ratio is to automatically search the optimal process of the controlled object with extreme nonlinear characteristics without knowing the mathematical system model, so as to ensure that the calculation function reaches or approaches the optimal value. Moreover, when the process environment changes, on the premise of giving priority to ensuring the extreme nonlinear relationship, the optimal value under the new process environment can be found through the automatic search function. According to the change rate of furnace temperature deviation, the change amount of gas calorific value can be reflected. Therefore, the furnace temperature deviation and the change rate of furnace temperature deviation are fuzzed, and the fuzzy expert rules are used to optimize the air-fuel ratio.

2.4 gas and air flow control

When the combustion load changes violently, the double cross limiting control method of gas and air flow can be used to control the furnace temperature. In order to limit the set value of the air flow and gas flow of the sub loop controller, the double cross limiting combustion control adopts to control the measured value of the air flow and gas flow. Through mutual restriction, it effectively prevents the possible excessive surplus of air and gas due to the rapid change of load. Ensuring that the combustion system always works in the best combustion area can greatly reduce the heat loss caused by peroxide combustion and anoxic combustion, and then minimize fuel waste and environmental pollution, so as to achieve the purpose of energy conservation, consumption reduction and environmental protection.

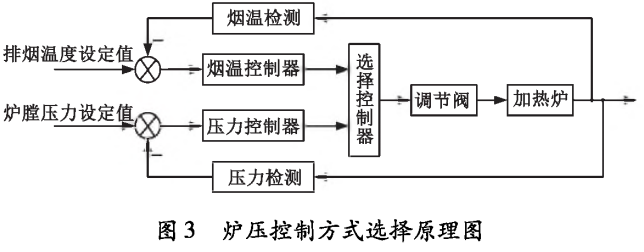

2.5 furnace pressure control

The selective control system of exhaust gas temperature and furnace pressure can be adopted for the furnace pressure control of the heating furnace. Under the normal condition of flue gas temperature, the furnace pressure controller can be selected by selecting the direct pressure control mode, so as to effectively control the furnace pressure and keep it stable; When the flue gas temperature is too high, the flue gas temperature controller can be used to control the flue gas temperature within the required range allowed by the process. The selection principle of furnace pressure control mode is shown in Figure 3.

① When the exhaust gas temperature is in the range of 100-200 ℃, select the controller as the furnace pressure controller to control the opening of the regulating valve, so as to effectively control the furnace pressure stability of the heating furnace.

② When the smoke exhaust temperature exceeds 200 ℃, select the controller as the smoke temperature controller to control the opening of the regulating valve, so that the smoke temperature can return to the allowable range of the process as soon as possible.

③ When the controller does not work, track the output of the working controller to realize the fast undisturbed switching between controllers, so as to meet the control requirements and realize the effective control of the system.

2.6 optimization of heating time

According to the different types of billets, the corresponding temperature rise curve should be reasonably formulated. At the same time, the residence time of billets in each section should be set according to the rolling rhythm of the rolling line. On the premise of ensuring the discharge temperature of billets, the time of billets in the high temperature section should be shortened as far as possible to reduce oxidation burning loss and save gas.

3. Waste heat utilization

The temperature of the exhaust gas discharged from the heating furnace is very high, which takes away a lot of waste heat. In order to improve the thermal efficiency of the heating furnace and save energy, the waste heat of waste gas should be used to the greatest extent. There are mainly two ways: one is to preheat air and gas by using the waste heat of waste gas, and bring part of the heat back to the furnace to improve the thermal efficiency of the furnace. The equipment used is heat exchanger or regenerator; The second is to use the waste heat of exhaust gas to produce steam and improve the utilization rate of heat energy. The equipment used is waste heat boiler.

4. Implementation effect

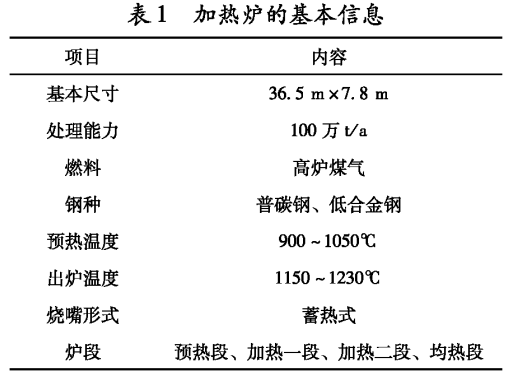

After in-depth analysis of the process flow and object characteristics of the heating furnace in a domestic steel plant, combined with the quantitative feedback theory and fuzzy control theory, the intelligent control system of the heating furnace is designed and implemented. The basic information of the heating furnace is shown in Table 1.

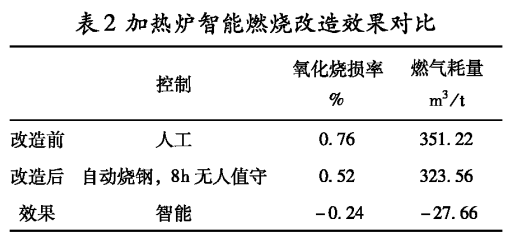

The application of the intelligent control system of the heating furnace effectively suppresses the influence of factors such as the calorific value of gas, pressure fluctuation and the change of parameters in the furnace on the operation of the heating furnace, improves the accuracy of furnace temperature control, realizes the optimal control of the combustion process of the heating furnace, realizes the purpose of saving gas and reducing oxidation burning loss, realizes the intelligent combustion of the heating furnace, and reduces the working intensity of workers. See Table 2 for the comparison of effects before and after the transformation.

According to the billet unit price of 2000 yuan /t and the output of 1million T / A, the amount of burning loss energy saving is calculated:

2000x0.24x100x104+104=4.88 million yuan

According to the gas unit price of 0.09%/m3, the saved unit consumption of 27.66m3/t and the output of 1million T / A, the amount of gas energy conservation is calculated:

0.09x27.66x100x104 ÷ 104=2489400 yuan