15358968703

Selection and principle of cold rolling oil

1. Preface

Whether the rolling oil is selected correctly in cold rolling directly affects the output and quality of the rolling mill Especially for the newly-built rolling mill, the cold rolling oil suitable for the characteristics of the mill must be selected to meet the requirements of rolling specifications and subsequent processes Based on the experience and data of five stand rolling mill, HC Rolling Mill and Baosteel five stand continuous rolling mill in Wuhan Iron and steel company, this paper puts forward the requirements of lubrication characteristics and annealing cleanliness of cold rolling oil suitable for circulation system.

2. Lubricity of cold rolling oil

Whether the original rolling mill or the newly-built imported rolling mill, there is a set of rolling specifications that meet the product large steel, and there is a minimum rolling thickness. In order to ensure that the rolling mill can smoothly produce the thinnest thickness, there must be corresponding cold rolling oil with certain lubricity An important indicator of the lubricity of cold rolling oil is the saponification value of the oil. The higher the saponification value, the better the lubricity of cold rolling oil But generally speaking, the price of synthetic ester series oil is also higher, so we must reasonably choose the lubricity of cold rolling oil.

2.1 elastic core theory

During cold rolling, the friction coefficient in the deformation zone has a certain relationship with the lubricity of cold rolling oil, that is, with the saponification value of oil The higher the saponification value, the smaller the friction coefficient in the deformation zone, and the size of the friction coefficient directly determines the thinnest thickness that the rolling mill can roll.

According to the elastic core theory of cold rolled steel strip [1], when cold rolled steel strip is rolled, the metal can turn into an elastic state without being pressed down in the deformation zone And in the central part of the deformation zone, so it is called elastic core The appearance of elastic core consumes rolling pressure in vain without reduction deformation, which is the fundamental reason for the difficulty of extension.

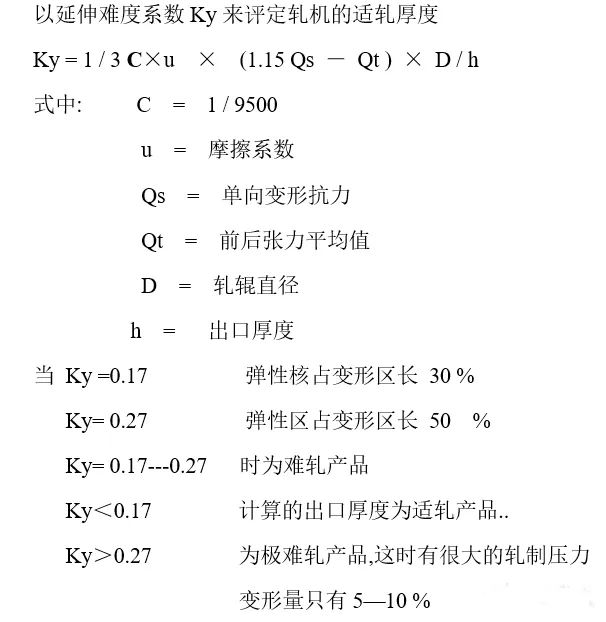

It can be seen from the above formula that the minimum rolling thickness is directly proportional to the friction coefficient u and roll diameter D For a certain rolling mill, the smaller the friction coefficient is, the thinner the rolling thickness is This depends on how lubricious cold rolling oil products are used.

2.2 relationship between friction coefficient and saponification value

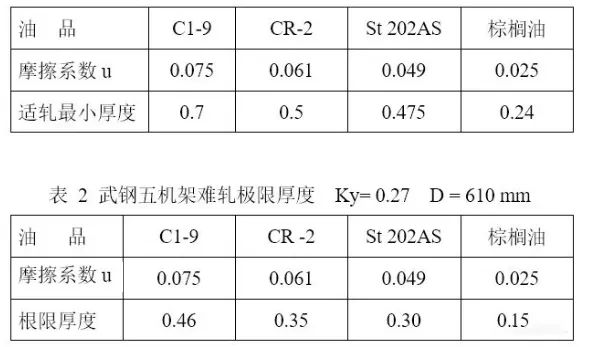

According to the production practice of the five stand tandem cold rolling mill of WISCO, the minimum thickness and suitable thickness of rolling difficulty can be calculated, and there is a certain corresponding relationship between the friction coefficient and the saponification value of cold rolling oil.

From the above figure and table, it can be seen that the friction coefficient decreases by about 0.012---0.014 for every 40 mgkoh/g increase in saponification value

The friction coefficient used in the design rolling procedure of WISCO HC mill is 0.036 According to the above theory, it is 0.033, and the two results are very close Cold rolling oil with saponification value of 130-160 mgkoh/g is now used in Baosteel five stand tandem cold rolling mill The friction coefficient u calculated by its model

1 # ---3 # rack u= 0.05

4 × rack u =0.04

5 # rack u= 0.16 use rough roller

The friction coefficient value (smooth roll) in the above calculation model is very close to the saponification value of 0.049 Therefore, from the relationship between elastic core theory and saponification value, we can estimate the suitable rolling thickness and difficult rolling thickness of certain material strip rolled by a certain mill On the contrary, according to the new rolling mill, a certain rolling specification can correctly select a certain lubricating cold rolling oil However, in production, there is oil leakage from the rolling mill equipment. The miscellaneous oil enters the emulsion corrosion ring system, which makes the saponification value of the original cold rolling oil decrease linearly Therefore, the saponification value of the selected cold rolling oil is 10-20% larger than the theoretical calculation value. In order to avoid the influence of miscellaneous oil on the rolling performance of cold rolling oil.

3. Comprehensive evaluation of cold rolling oil

Although the cold rolling oil has the same Huang chemical value, its lubricity is still different As shown in Figure 3 Compared with lard, palm oil with saponification value of 200mgkoh/g has better lubricity than lard Similarly, the lubricity of pure palm oil or pure lard with 3-5% oily agent is much better than that of pure oil Therefore, the cold rolling oil with the same saponification value must be comprehensively evaluated to select the cold rolling oil that more meets the process conditions

Use the above method to select cold rolling oil It is not applicable to 20 high senjimiho mill Because the lubricity of Pan rolling oil is too good, it is easy to cause the roll system to slip Generally, the saponification value of cold rolling oil used for 20 roll Sendzimir roll is less than 95mgkoh/g

3. Annealing detergent cold rolling oil is required to have good lubricity

However, if the rolled coil is directly rolled and annealed in the bell type annealing furnace without electrolytic degreasing, then there is a higher requirement for the cold rolling oil, that is, it has good annealing cleanliness. This kind of rolling oil is called "rolling oil for mill clean steel plate (MCS)." Especially for the bell type annealing furnace with 3-5% H2 and 95-96% N2 as protective gas Generally speaking, the surface of the annealed steel plate of the full hydrogen furnace should be clean

MCS rolling oil must have low volatilization temperature, good oxidation resistance, thermal degradation performance, and diffuse reflectance of the plate surface after annealing ≥ 70% -- make the dirt on the surface of the steel plate copy on the colorless transparent tape, stick this tape on the white hard paper, and measure the brightness (y value) by reflection method The percentage is expressed by 100% of the dirt free blank tape (the diffuse reflectance of the surface of the electrolytic degreased annealed strip steel is 95%)

The reasons affecting the annealing cleanliness are as follows;

3.1 changes in physical and chemical properties of emulsion

The changes of physical and chemical properties of emulsion are caused by physical and chemical changes in emulsion Fine particle pollution will occur in physical changes, mostly due to the fine iron powder scraping off the roll and strip steel Chemical changes are the deformation heat and friction heat used in the deformation zone, which promote the oxidation of the oil film under the action of iron powder contact enzyme, and decompose the oil of the oil film into carbonyl. Carbonyl and iron powder form iron soap to form oil stain At the same time, the iron soap will also decompose and deteriorate and react with the surface of the steel plate to produce an oxide film, so the oil stain generated by the chemical reaction is caused by the oxide deterioration of the used rolling oil The oxide film on the surface of the steel plate and the oil stain attached to it directly affect the annealing cleanliness of the cold rolled plate

3.2 edge carbon

During bell annealing, the edge carbon is produced due to the oxidation and reduction of the rolling oil contacting the protective body at the edge of the strip steel Or carbon precipitation and discoloration The formation of this kind of edge carbon not only has the most suitable temperature, but also the temperature gradient during heating is an important reason Rolling oil volatilizes into low hydrocarbons, carbon monoxide, carbon dioxide, etc. at high temperature Carbon monoxide reacts with the surface of steel plate;

3Fe +4CO ------- Fe3O4 + 4 C

Carbon is formed The precipitation amount of carbon has a maximum value at 500-600c Especially, the fine iron powder produced during rolling is attached to the surface of the steel plate, which increases the surface area of Fe and promotes the generation of edge carbon.

Generation of black ash

The carbon content is more than 0.02%, especially when the low carbon steel containing Si is heated at 650-700 C for several hours, the carbon precipitates from the surface and grows into well crystallized graphite. The factors affecting the black ash include temperature, time, coil tension, protective atmosphere, carbon content in steel, and surface composition segregation In addition, rolling oil volatilizes into methane, ethane and other low-carbon compounds at high temperature, and carbon can still be separated out after further decomposition Therefore, if the annealing elbow is kept at low temperature for a period of time and the purging time of the protection body is increased, it is conducive to the volatilization of rolling oil and can reduce the generation of black ash. Generally speaking, with the increase of saponification value of cold rolling oil, the annealing clarity will be reduced. With the development of science and technology, the saponification value of rolling oil has been applied to 160mgkoh/g, and it still has the good performance of direct annealing without degreasing of Dendrobium For example, CRD series rolling oil of Wuhan Yangtai company.

4 Conclusion

Cold rolling oil directly affects the output and quality of rolling mill The use of appropriate cold rolling oil must meet the process lubrication of the rolling mill and its subsequent processes. There is a certain relationship between the friction coefficient obtained by using the elastic core theory and the saponification value of the cold rolling oil, so the cold rolling oil can be reasonably selected. If there is no electrolytic degreasing unit after rolling, the "rolling mill clean steel plate" (MCS) rolling oil must be used.

The above method is suitable for selecting the rolling oil of cold rolled plain carbon steel series for rolling, but not for 20 high Sendzimir mill.