Finishing area process technology operating rules, rod line technology

1. Cold bed

1.1. effect

After rolling, the double ruler is accelerated, braked, and sent to the cold bed for cooling and grouping to ensure that the double ruler on the cold bed is straight and one end is aligned.

1.2. Equipment composition and characteristics

The length of the input roller table in the cold bed area is 200 meters, the number of input rollers is 146, the spacing is 1.2 meters, the line speed is 3~23 meters/s, and the motor of the roller table is regulated by frequency conversion. Input roller table area equipment includes front roller table, input roller table, brake plate and its transmission hydraulic cylinder, straightening plate, etc. Cold bed (L X W) 12.5X120 m, including rack and beam assembly, cold bed drive, alignment roll and bar lift; The operation cycle of the cold bed is about 3.55 seconds, and the drive motor is DC speed adjusted. Alignment of roller line speed 0.12~0.97 m/s, roller motor frequency control. The output part of the cold bed includes the chain conveyor and its transmission device, the batch lifting transport car and its transmission device, the output roller table and the lifting baffle, the distance between the chain and the car is 1.6 meters, the output roller table length is 156 meters, the line speed is 1~2.2 meters/second, the roller motor frequency conversion speed regulation; Number of rolls 60, spacing 1.6 meters.

The input roller is directly connected with the motor to drive the roller. The motor is fixed to the roller table support.

The alignment roller table is a motor direct reducer, the output shaft of the reducer is connected to the sprocket, and the alignment roller shaft head is also a sprocket, which is driven by the chain.

The output roller table is a motor directly connected reducer, which is directly connected with the roller to realize the transmission of the roller.

Between the input roller table and the straightening plate, there are 11 hydraulic cylinders to drive the lifting brake plate. The hydraulic cylinders drive the crank, and the crank works jointly through a long shaft. The brake plate with a total length of 156 meters works simultaneously and lifts together.

The movable beam and fixed beam in the cold bed body are a frame structure composed of some beams and longitudinal beams, and the above is a row of vertical rolled center line, the distance is basically equal to the rack, the total length of the rack is about 8.125 meters. The rack on the movable beam moves with the movable beam driven by the cooling bed transmission device. When the movable beam rack moves to the same height as the fixed beam rack top, the groove shapes of the two rack teeth coincide in the direction parallel to the rolling center line.

The transmission device in the cold bed body is the motor drive worm gear reducer, and the output shaft of the reducer drives a long shaft, (the length of the long shaft is about 96 meters), which is formed by the shaft of ~ 4.3 meters through the coupling. A set of eccentric mechanism is used on the transmission shaft of the cold bed to make the moving beam on it move. The motion path of the rack beam is a circle in the vertical plane.

The transmission device of the chain conveyor and the batch lifting trolley is the motor driven bevel gear reducer, and the output shaft of the reducer drives a long shaft, (the length of the long shaft is about 96 meters), which is formed by 5 to 6 meters of the shaft connected through the coupling. The chain transport is a set of sprockets on the shaft, and the chain is moved on the chain beam by the sprocket traction chain, and the transport car is moved by the chain traction. There are 5 sets of transmission devices for the chain of row fabric transport chain and lift transport trolley.

In the transmission of the equipment, the cold bed input roller table brake plate and the lifting transport trolley are driven by hydraulic cylinder. Input the steel puller on the roller table, align the bar lifting device at the roller table, and output the lifting baffle at the exit of the roller table is driven by the cylinder. The motor driven equipment includes input roller table, alignment roller table, output roller table drive, cold bed drive device, distribution transport chain and batch lift trolley transverse drive device. Through the rotary encoder and proximity switch, photoelectric switch to ensure the movement of the equipment in place and safe operation. The hydraulic cylinder is powered by hydraulic piping, and each rotating pair is lubricated by dry oil piping and manual refueling.

1.3. Controls

1. 3.1. Button operation instructions

1) During normal production, each status button is in automatic control state.

2) When parking, make each status button in the "maintenance" state.

1. 3.2. Preparation before driving

1) Check the bed surface to make sure there is no debris.

2) Understand the alarm information and operation of the last shift.

3) Cooperate with the cold bed operator to test the equipment in the cold bed area in the manual state to check whether the operation is good.

4) According to the product specifications, set the length of the double ruler, the number of the double ruler, length, short and other parameters, click "TAKE OVER" on the screen to check whether the parameter setting is reasonable.

5) Select the number of full-head roller groups according to product specifications, and set its speed on the interface; For Φ14 and below specifications should be put into the cold bed lifting device, and set the lifting delay time.

1. 3.3. Start and run

1) Complete furnace steel feeding according to the following requirements.

a. When the material tracking management system is put in, it will be completed automatically, pay attention to the confirmation when changing the number.

b. Manual operation, a furnace number rolled, after the operator of the 3# station notified and confirmed, press the manual button of the moving rack, so that the middle of the two furnace numbers left two slots.

c. According to the above rules when changing the furnace number, more than four tooth slots should be empty between the double feet of the two furnace numbers, so that the grouping chain can be emptied.

d. When changing the furnace number, the steel of the previous furnace number should be moved one long step away from the organizing chain; When the furnace number is changed, all the steel of the previous furnace number is removed, and then the next furnace number is organized.

e. Notify 5# operator.

f. Notify quality inspection personnel to take samples.

2) Ensure the cooling quality of rolled parts, and decide the cooling method of rolled parts according to the technical performance of rolled parts.

3) According to the production situation, control the production rhythm of the finishing area, and adjust the capacity parameters if necessary.

1.4. Abnormal accident handling:

1.4.1. If the rolled parts cannot be accurately placed on the cold bed, reset the "position of the cold bed on the correction rule".

1.4.2. The rolled parts can not be guaranteed to be straight, check whether the skirt surface is the same height, check whether the electric interlock of the moving rack, the assembling chain, the lifting car and other parts is synchronized, and adjust it if necessary.

1.4.3. When the bend at the end of the double scale is serious, the lead coefficient of the double scale shear is reduced.

1.4.4. The double ruler can not arch or arch after the head, and the lifting delay of the lifting device should be adjusted.

2. Cold flying scissors

2.1. Equipment parameters, composition and function:

2.1.1 Process parameters

Incoming material specification: Æ10~ 50mm

Incoming material speed: 1.0~ 1.5m /s

Incoming material temperature: ≤300℃

Shear steel: carbon structural steel, high quality carbon structural steel, cold heading steel, alloy structural steel, low alloy steel.

2.1.2 Device Performance

Cutting machine number: LFJ450-1.5, crank and link type

Maximum shear force: 4500 kN

Rolling speed: 1~ 1.5m /s

Shear maximum diameter: Æ50 mm

Shear temperature: ≤300℃

Minimum measuring length: 6 m

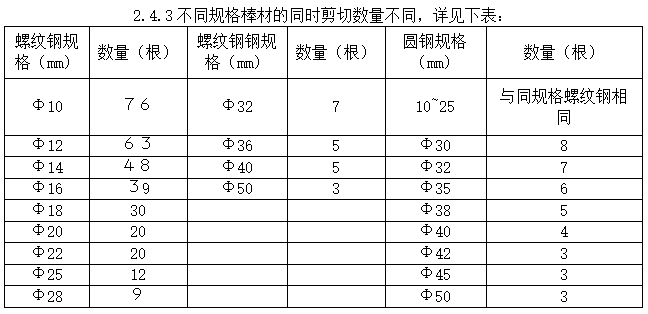

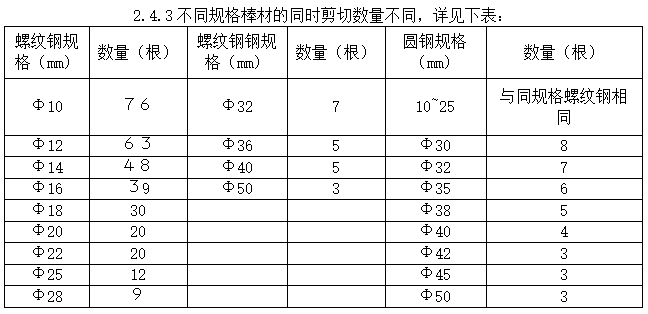

Number of shear rolled pieces: See shear system

Motor model: ZTFS-450-22, 2 sets

Power: N=750 kW, 660V

Speed: 0~750 r/min

Cutting edge turning radius: R=250 mm

Total speed ratio: i=9.597

2.1.3 Components

Cold bed output, output roller, press roller, lifting baffle, cold shear before and after electromagnetic roller, swing roller, cutting head collection device.

2.1.4 Action

The double scale group after the full head is neatly sent to the cold flying shear for cutting, and the fixed scale (or short scale) group is sent to the collection bench.

2.2. predrive

2.2.1. Understand the alarm information and operation of the last shift, check whether the parameter setting is reasonable.

2.2.2. Cooperate with ground personnel for equipment inspection and sensor inspection.

2.2.3. Press the LAMp-test button to check whether the console button light is normal.

2.2.4. Contact with the ground personnel to confirm, point test, confirm that the equipment works well.

2.3. Controls

2.3.1. Cold cut outlet status button is selected in automatic state.

2.3.2. Set measuring length according to production requirements.

2.3.3. According to the bar specifications, set the output roller table of the cold bed, accelerate the speed of the roller table after cold cutting, and adjust the shear length in time according to the cutting situation in the production process to ensure the precision of the measuring.

2.3.4. According to the length of the cut end, the length of the double size should be corrected in time to improve the yield and the size ratio.

2.3.5. When a set of double scale cutting is finished, if there is a steel head around the cutting edge and on the roller table, the cold shear operator should be informed to deal with it before cutting.

2.3.6. When product specifications change, cooperate with the cold shear operator to adjust the height of the cold shear roller table.

2.3.7. When changing the length of the Length, reset the customer.Length, and notify the operator of the 5# station, and start cutting after confirmation, and adjust the corr.Length to ensure the cutting accuracy of the length.

2.3.8. Stop cutting when changing the number and inform the operator of station 5#. If the furnace number is changed, the steel of the next furnace number can be cut only after the 1 # conveyor chain has no steel; If the steel number is changed, it must be cut after there is no steel on the 1 # ~4 # conveyor chain.

2.3.9. When changing the cutting edge, the cold shear inverter and dry oil station are stopped and powered on the screen, the manual speed of cold shear is set to 0, and the electrician is responsible for stopping and powering the cold shear.

2.4 Shear system of cold flying shears

2.4.1 The minimum length of cold flying shears is 6M, which is determined by the start-stop working system of flying shears.

2.4.2 Use a flat cutting edge to cut bars with a diameter of less than 25MM, and use the corresponding pass cutting edge when cutting bars and steel with a diameter of more than 25MM (inclusive). When using the pass cutting edge, it is necessary to replace the press roller and grate that match the pass cutting edge at the same time.

2.5 Adjustment and setting of cold shear

2.5.1 Adjustment of cold flying scissors

The adjustment of the cold flying shear can only be carried out on the basis of correct installation and acceptance of the equipment.

The adjustment of cold flying shear shall be carried out according to the requirements of the drawing.

The side clearance of the cutting edge of the cold flying scissors should be adjusted to 0.3-0.4mm. When adjusting the clearance of the cutting edge, the gear side backlash should be eliminated first, and then the clearance of the cutting edge should be adjusted to 0.3-0.4mm by grinding the gasket.

The maximum cutting edge contact is 5mm. The contact degree of cutting edge is adjusted mainly by grinding cutting edge and adding gasket.

The adjustment of the inlet and outlet guide plates should be carried out on the principle that the rolled parts can be smoothly imported and exported to the flying shears and ensure the minimum deformation of the rolled parts.

Each rotating part should operate flexibly, without blocking phenomenon, and adjust the bearing clearance if necessary.

The position adjustment of the encoder or proximity switch is performed according to the requirements of the electrical control,

Manual turning, so that the cutting edge rotation for several weeks, to confirm that no collision phenomenon occurs.

2.5.2 Starting position of the cutting edge: 90° position after the cutting edge teeth are fastened

Shear speed setting of cold flying shears: set according to the actual speed of the output roller table of the cold bed.

Preliminary setting of lead rate of cold flying shears:

Lead rate =250/ (250-h)

Where: h= section height of the cut rolled piece.

The lead rate can be adjusted according to the specific situation during the test.

Length setting: according to the process requirements, the minimum is not less than 6m

2.6. Abnormal accident handling

2.6.1. The output roller of the cold bed has random steel, which should be manually operated and dealt with by the cold bed operator.

2.6.2. If there is a double size superposition, it must be flattened and then cut, eliminate superposition shear, and prevent the top cutting edge or fixed size elbow.

2.6.3. If the measurement is not correct, check whether the magnetism of the electromagnetic roll and the grating signal are normal, and whether the speed of the acceleration roller after cutting, the height of the swinging roller and the positioning of the press roller are appropriate.

2.6.4. In the shearing process, the double ruler runs to one side, especially the rebar, which is generally caused by the shaft error, notifying the finishing mill adjuster to eliminate the shaft error.

3, the size collection device

3.1. effect

After counting, the measuring material is transferred to the baling device for baling or stacking.

3.2. Controls

3.2.1. Preparation before driving

1) Understand the operation of the equipment in the previous shift.

2) Cooperate with the inspection of whether the detection element is effective, if there is dirt at the detection head, it should be cleaned in time.

3) Cooperate with the conveyor chain operator to click the operation in the manual state to check whether the equipment is running normally.

4) After taking OVER or setting parameters, click "TAKE OVER" on the screen to check whether the parameter setting is reasonable.

3.2.2. When the length is >6m, contact the operator of the conveyor chain to confirm, and close the two-line clutch together, so that the two lines operate at the same time, the operation is as follows:

3.2.3. Reset the rotating arm and set the unloading position.

3.2.4. Set the alignment roller speed and alignment time according to the rolling variety.

3.2.5. Set the speed of each chain segment according to the production specifications and equipment conditions.

3.2.6. Counter and rod layer separation device: set the number of finished bundles, keep the chain and count speed, and set and adjust the speed of 1 # and 2 # chains in proportion at any time to ensure the smooth progress of counting.

3.2.7. Operation using a layer width counting device

Adjust the electromagnetic flip arm to the initial position.

According to the production specifications and technological requirements, the position of stop block and proximity switch is adjusted by worm gear mechanism.

Adjust the position of the baffle plate and the proximity switch of the electromagnetic turning arm according to the width of the layer.

When the length of the finished material is 6 meters and below, the clutch of each equipment is opened, and each area can be divided into two separate actions, and the operation method is the same.

3.3. Rules when changing numbers:

When receiving the notice to change the number of the 4# operator platform, the position of the new and old rod layers should be clear, and the conveyor chain operator should be notified to pay attention to avoid mixing.

When changing the furnace number, it is necessary to wait until there is no steel on the 1 # chain before steel can be fed; When changing the steel number, it is necessary to wait until there is no steel on the 1 # ~ 4 # chain before steel can be sent, and inform the hanger-on the last one (or two) of the specific location.

3.4. Abnormal accident handling:

If there is random steel in this area, press the Q-STOP button immediately and notify CP4 to STOP sending steel to this area.

The counter should be stopped immediately when stacking steel, find out the cause and eliminate before continuing production.

When using a stacker, if the steel slides to the end of the 4 # chain, the rollover arm will be stuck when turning, at this time, it should stop immediately and start after the steel is removed.

4. Fixed length bundling device

4.1. Controls

4.1.1. Preparation before driving

1) Understand the operation and operation of the last shift equipment.

2) Cooperate with the conveyor chain operator to manually check whether the equipment is running normally, whether the rotating arm and the bundling arm are synchronized, and report to the monitor in time if there is any problem.

3) Check the lubrication of the equipment according to the requirements of the equipment inspection rules, and deal with any problems in time.

4) Before driving, the equipment will be powered off, set the process parameters according to the variety, and notify the conveyor chain operator.

5) Work with the conveyor chain operator to adjust the width of the vertical roller table according to the size of the finished bundle.

4.1.2. job

1) When the length is 6m or below, open the clutch device and select two lines on the panel to handle two rows of 6m bars at the same time or a single line to handle a row of 6m bars; When the size is greater than 6m, the two lines must be synchronized.

2) Pay close attention to the operation during operation, and revise the process parameters if necessary to ensure smooth production.

3) When determining the packaging, it is necessary to confirm the number of collected layers, and keep in close contact with the operator on the measuring scale collection device platform to ensure the accuracy of the number of finished bundles.

4) When changing the number, contact the operator of the 4# platform and the operator of the conveyor chain, collect the steel of the first one, then collect the steel of the next one, and inform the hangman of the exact location of the last one (or two) bundles of the first one.

4.2. Abnormal accident handling

4.2.1. During the operation, if the bar deviates, it should be stopped immediately, and cooperate with the conveyor chain operator to deal with the accident.

4.2.2. If there is a steel jam, steel accident, should follow the command of the chain personnel to operate, to prevent equipment accidents.

4.2.3. When an emergency occurs or a device fault occurs, press the e-STOP emergency STOP button and handle the fault quickly. Perform operations only after the fault is rectified.

5. Bundle

5.1, manual baler packing belt packing requirements:

1. 9m packing belts are evenly distributed, and the middle two packing belts are evenly distributed (the distance from each near end is approximately equal), and the head is played twice, the distance from the end is 300 ~ 500m. The diagram is as follows:

2, 12m fixed length packing belt play 7, the packaging diagram is as follows: the middle of the approximate middle position, the other middle two distance from the end of about 3000mm, the end of each play two, distance from the end of 300 ~ 500mm.

5.2, automatic baler packing rod packing requirements:

1. 9m packing rod is evenly distributed, the middle two packing rods are evenly distributed (the distance from each near end is approximately equal), and the head is each played with one rod, the distance from the end is 600-900m. The diagram is as follows:

2, 12m fixed size packing rod to play 5, the packaging diagram is as follows: the middle of the approximate middle position, the other middle two from the end of about 3000mm, the end of each play two, from the end of 600 ~ 900mm.

5.3. Specific packaging requirements:

The binding should be firm, ensure that one end is flat, the length difference of the other end is not more than 20mm, the steel shall not be cross-pressed, and there shall be no mechanical bending. The steel bundles after wrapping must be in good condition during the normal lifting, delivery and loading process, and a large number of broken belts and bales such as bulk bales are not allowed to occur.

When packing the automatic baler, if there is a large number of broken belts due to material problems and other reasons, it is necessary to add one package at the end. In addition, in the case of a small number of additional branches, it is necessary to completely unpack and re-pack after adding branches, and the repackaged steel bundles are not allowed to include packaging materials and packaging belts.

6, finishing area outside the operation table operating procedures

6.1. Cold bed operation

6.1.1. Responsibilities: Work with the 4# operator to ensure the smooth operation of the equipment in the cold bed area.

6.1.2. Preparation before production

1) Understand the production and equipment operation of the last shift.

2) According to the provisions and requirements in the Equipment Use and Maintenance Regulations, check the 3 # scission roll table, 3 # scission acceleration roll table, upper cooling bed roller table, cold bed, head roller table, lifting device, forming chain, lower cooling bed roller table, and lifting apron after cold bed.

3) After the completion of the above work and safety confirmation, notify the 4# operator to test the equipment, at the same time, find problems in time to deal with, and then notify the 4# operator to drive.

4) Check whether various detection components are reliable, and remove impurities such as oxide sheet that affect the detection signal in time.

5) Prepare and check the tools used.

6.1.3. Controls

1) During production, pay attention to observe the operation of skirt plate, rack, head roller table, assembling chain, lifting trolley, output roller table and other equipment, and contact the 4# platform operation table if any problem is found, and deal with it in time to ensure the smooth progress of production.

2) Pay attention to observe the quality of the bar surface, and notify the hot inspection worker of the rolling mill in time when the problem is found.

3) When rolling round steel and rebar of Φ28 and above specifications, responsible for installing comb.

4) Due to various reasons caused by bending steel, random steel, the shift must be dealt with, so that the site clean shift.

6.1.4. Abnormal accident handling

1) Observe the situation of the double scale into the cold bed, if the double scale cannot be correctly cooled on the ground, notify 4# station to stop the steel, return the wrong channel steel to the team, can not be saved to cut or cut out the cold bed, to ensure that the double scale layer into the cold shear flat, no stack steel.

2) When the ruler is thrown into the cold bed, the bending phenomenon is serious, and the operator of the 4# platform should be notified in time to stop, find out the reason, and the skirt plate is levelled before driving.

6.2. Cold shear operation

6.2.1. Responsibilities: Cooperate with the 4# platform operator to ensure the smooth operation of cold shear.

6.2.2. Check and prepare before production

1) Understand the production and equipment operation of the last shift.

2) Carry out spot inspection and maintenance of the equipment according to the "Equipment Use and Maintenance Regulations".

3) Check and prepare the tools used.

4) Check the tightening, wear and breakage of the cutting edge, and if there is a problem, tighten or replace it in time.

5) Check whether the photocell is reliable before and after cold cutting, and remove the surrounding debris in time.

6) After the completion of the above work and safety confirmation, notify the 4# station operator to manually test the equipment, at the same time, find the problem to deal with in time, and then notify the 4# station operator to drive.

6.2.3. Controls

1) During production, pay attention to the operation of cold shear and auxiliary equipment. If any abnormality is found, the operator of 4# station should be notified, and the person in charge of the operation area should be contacted to deal with it in time to ensure that the equipment is in good operation.

2) Pay attention to observe the bending condition of the double ruler group during shearing, judge the wear degree of the cutting edge, and decide whether to replace the cutting edge.

3) Timely clean the cutting head and tail that do not fall into the chute before and after the cold shear to prevent the cold shear from getting stuck.

4) Clean the bar head, tail and short scale on the cold-cut roller table in time to prevent the photocell from sending out wrong signals.

5) Assist the cold bed operator to deal with random steel in the cold bed area.

6) When changing the cutting edge of the pass, replace the guide roller with groove at the same time.

7) When changing the product specifications, adjust the height of the cold shear roller and the positioning of the press roll, the adjustment steps are as follows:

① Manually move the bar layer to the cold shear position, but do not put the head on the swinging roller after the shear, and press down the swinging roller before the shear.

② Manually move the cutting edge so that the upper and lower cutting edge distance is 20 ~ 3mm below the bar layer.

③ Adjust the height of the swinging roller before cutting so that the bar layer is equidistant from the upper and lower cutting edges.

④ Manually reverse the cold shear blade, and manually slowly move the bar layer forward, so that its head exceeds the post-shear swing roller, and press down the post-shear press roller.

⑤ With the second step, adjust the height of the swinging roller after cutting, so that the bar layer is equidistant from the upper and lower cutting edges.

8) Clean up the debris around the cold scissors before work, so that the site is clean.

6.2.4. Abnormal accident handling

1) When the chute is stuck, the operator of the 4# platform should be notified to suspend the cutting, and after confirming the stop, use a long hook to hook and poke, so that the steel head slides smoothly into the cutting head basket.

2) When cold cutting the crank steel, the operator of the 4# platform should be informed to power off the cold shear, and after confirming the stop, use the straight head cut to cut the sweep and clear the steel head between the crank and the inertia wheel.

6.3. Short scale collection and sampling operation

6.3.1. Responsibilities: Complete the assembling, collection, packaging, weighing and storage of random ruler; And sample as required.

6.3.2. Production preparation:

1) Understand the equipment operation and sampling of the previous shift, and implement the shift handover system.

2) Carry out spot inspection and maintenance of the equipment according to the "Equipment Use and Maintenance Regulations".

3) Contact the operator of unit 5# to conduct the test run of the equipment and confirm that the operation is good.

6.3.3. Driving and operation:

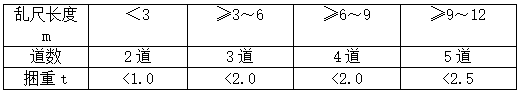

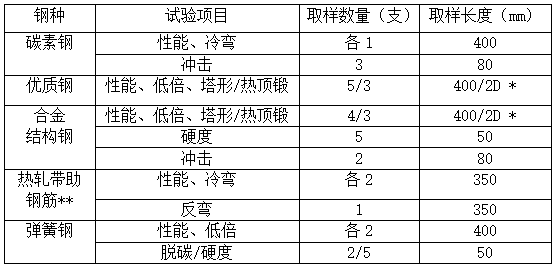

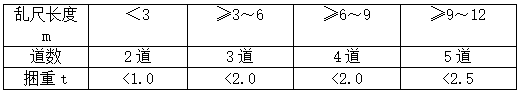

1) According to the bundling requirements in the following table, use the binding wire to bind manually, and make it all together.

2) When binding, stop the short ruler chain to prevent the short ruler behind from falling down.

3) Write the steel number, specification, frequency, etc., on the sign, and hang it at both ends of the bundle (1 at each end).

4) Check the furnace number and steel number of the steel feed card before sampling, and then sample.

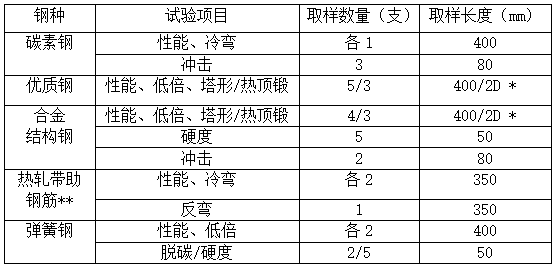

5) According to the requirements of the table below, sample on the short scale of each furnace, one short scale can only take one sample.

Note: *D indicates the diameter of the product; * * The full name is "Hot rolled strip reinforcement for reinforced concrete".

6) Print/write the steel number, furnace number, specifications and other contents on the sampling plate.

7) Bind the sample in two strips with fine iron wire, hang the label, and put it in the sampling bucket.

8) When changing the steel number, contact the operator of the 4# platform, collect and bundle all the short feet of the previous steel number, and then collect the short feet of the next steel number.

9) When large size short size is stored according to the random size material, the product and packaging standards should be strictly implemented, and the storage procedure should be handled according to the fixed size bundle, and the random size material should be stacked separately (tic-tac-toe).

10) When the short scale chain appears random steel or uneven, it should be straightened and pulled together in time to ensure that the short scale bundle is neat.

6.4. Conveyor chain operation

6.4.1. Responsibilities: Work with the 5# table operator to ensure the smooth operation of rolled pieces from the conveyor chain to the finished product collection chain.

6.4.2. Production preparation:

1) Check whether the rotating arm, electromagnetic turnover arm, 1 ~ 4 # chain and roller table are running normally, carefully check the chain tensioning condition and whether the operation is stable, whether there is fracture phenomenon, and check to confirm that the detection components are working normally.

2) When the product needs to be counted, check the counter and all lifting devices together with the 5# operator, if there is a problem, it should be adjusted in time to ensure its normal operation.

3) Carefully check the parts of the binding machine that are easy to wear, such as: threading plate, knot head, chute, etc., to be replaced in time. Purge the iron oxide in the chute, and clear the chute such as the wire head in time.

4) Check whether the commonly used tools are complete and easy to use.

6.4.3. Start and run

1) During normal production, pay attention to check the cutting accuracy of the length, and notify the 4# operator in time if there is a problem.

2) Pave and straighten the overlapping steel and random steel to be counted in time to ensure the accuracy of the steel count, and notify the operator of the 5# table to adjust the parameters.

3) Ensure the smooth transportation of steel in production, and pick out in time when there are short feet or unqualified products mixed.

4) Pay close attention to the change of the furnace number and steel number, and confirm the exact position of the last bundle or two on the first one with the operator of the 5th # platform and the hangman to prevent mixing.

5) Adjust the width of the vertical roller table according to the size of the bundle.

6.4.4. Abnormal accident handling

1) When the conveyor link is skewed by the bar, it should be straightened in time to prevent the bar from jamming the chain.

2) When there is random steel, notify the 5# operator to stop, after confirmation, together to clear the random steel.

3) The top chain of the finished product: the failure of the detection component causes the action to be out of control, check the detection component, if it can not be handled, notify the electrical repair personnel to repair.

6.5. Listing operation

6.5.1. Responsibilities: Check the consistency of the label with the steel delivery card, and list and store.

6.5.2. Main equipment: Label printer: 1 set/area.

6.5.3. Production preparation:

1) Understand the operation of the equipment in the previous shift.

2) Understand the production information of the previous shift, such as furnace number, steel number, product specifications, etc.

3) Carry out spot inspection and maintenance of the equipment according to the "Equipment Use and Maintenance Regulations".

4) Prepare aluminum signs and thin iron wire.

6.5.4. Controls

1) Check the furnace number, steel number and specifications of the material tracking system.

2) After confirming that the printed label is correct, hang it on both ends of the finished bundle as required.

3) When changing the steel number, the crane must be directed to put all the bundles of the upper steel number into the warehouse, and then lift the materials of the lower steel number.

4) When there is a waiting for inspection, the two signs are hung on the same end of the bundle, notifying the lathe worker to put it in the waiting position of the class, and make a record on the "class output Material Record".

5) Materials to be inspected shall be processed into the warehouse, and records shall be made in the "class output Material Record" of the shift.

6) Ground station operation:

Set the selector switch to the LOCAL bit.

Press the START button for "Unbundle";

Select the working line of the bundle collection bench, and control the advance/retreat of the first and second sections through buttons, as well as the first chain rise/fall.

6.5.5. Abnormal accident handling

1) When the label is printed incorrectly, the weight of the bundle is entered into the weighing computer to print the label again.

2) When the ends of the finished bundles are uneven, they should be hit with a sledgehammer, or lifted out for inspection first, and then put into the warehouse after processing.