15358968703

[case] summary of bearing failure of bar roughing mill

Recently, the rolling element and outer ring of the bearing of the roughing mill of the bar line have often been damaged and cracked in a short time, and three on-line burning failures have occurred within 30 days, which has seriously affected the monthly production capacity target. Therefore, the bearing manufacturer and on-site technicians are specially invited to find out the causes of this failure.

The causes were found mainly for the bearing assembly site, roll diameter, bearing housing and sealing. After a series of troubleshooting, the following problems were found:

Problems and phenomena

1. All the damaged bearings are cracked on the outer ring near the roll body side, which can be judged as a damage law.

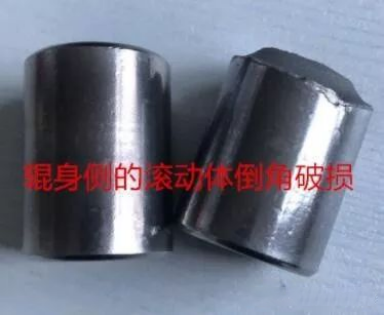

2. The damaged bearings are also damaged at the chamfer or worn at the end face of a row of rolling elements near the roll body side.

3. The bearing outer diameter is under abnormal stress, especially the bearing flange is under abnormal load.

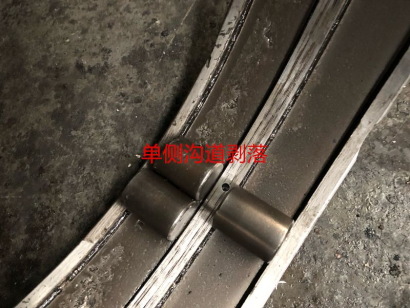

4. After disassembling the bearing that is not damaged but the rolling element (near the roller body) is abnormally damaged, it is found that the bearing is stressed on one side and the groove on one side is peeled off.

5. The bearing box, especially the inner hole of the lower roll bearing box, has a sinking phenomenon in the stress area. After measurement, large irregular ellipse and taper out of tolerance appear.

6. The limit step of the frame base that restricts the left and right movement of the bearing housing is seriously worn, resulting in an abnormal increase in the clearance between the frame and the bearing seat, and abnormal matching of the clearance of the new base.