15358968703

Data governance in industrial digital transformation

With the explosive growth of data resources, enterprises are facing problems such as inconsistent data standards, scattered data information, uneven data quality, and difficult development and maintenance. It is difficult to meet the high requirements of real-time analysis and decision-making. Therefore, data governance is crucial to the development of industrial Internet.

Development status of data governance

1、 Related concepts of data governance

Data governance is the management behavior of data use and management in an organization. Its essence is to guide, evaluate and supervise the management and utilization of data, improve the quality of data by formulating a data standard system, and provide organizations with innovative data services to improve the value density of data. Data governance mainly includes modules such as metadata management, master data management, data standard management, data quality management, data lifecycle management, data organization, data security and data services. Different modules have clear functions and cooperate with each other to jointly create an information sharing service system with unified scheduling, accurate services and safe availability.

2、 History of data governance

The history of data governance can be divided into three stages. The first stage is the early exploration stage. The comprehensive data quality management plan launched by MIT in 1988 has formed the rudiment of data governance. In the same year, the International Association of data management organizations (DAMA) was established. In 2002, the concept of data governance emerged in the academic circles. Two American scholars proposed the research direction of data governance based on the practical results of the two companies, thus opening the curtain of data governance in enterprise management. The second stage is the theoretical research stage. In 2003, the International Data Governance Institute was established to study the theoretical framework of data governance and define data governance in cooperation with the international organization for standardization. In 2009, Dama issued a guide to data management knowledge system, basically determining the theoretical framework of data governance. The third stage is the stage of wide acceptance and application. With the construction of data warehouse, China has gradually begun to accept the concept of data governance, and put forward the Research Report on international standards of the white paper on data governance in 2015.

Since 2020, data governance has been widely used in public management, scientific research, industry and commerce. The "Internet +" system with data as the core has increasingly highlighted the value of data governance. In order to further promote the development of data governance, the United States and the European Union have promulgated public policies around data use and protection. China has also successively issued relevant policies such as made in China 2025 and the guiding opinions on deepening the development of industrial Internet through "Internet + Advanced Manufacturing" to promote the development of industrial Internet, which further reflects the necessity of industrial data governance.

3、 Exploration of industrial data governance

Industrial manufacturing mainly includes business scenarios such as equipment fault early warning, abnormal real-time alarm, abnormal backtracking, product stability and production efficiency optimization. With the in-depth promotion of strategic policies such as intelligent manufacturing and industrial Internet, industrial enterprises have accumulated a large amount of data to provide high-quality data interfaces for data analysis under different business scenarios, making industrial data governance a core issue. This paper will take industrial data as the core, data governance as the method, and business application as the purpose to build a data governance system for industrial production and manufacturing, and verify the effectiveness of data governance through case practice.

Industrial data governance system

1、 Industrial data situation

① Industrial data sources

Industrial data can be divided into operational technical data (OT) and information technology data (it). OT data is the main part of industrial data, which comes from industrial production machinery and equipment, automatic acquisition system, etc., including time-series data and non time-series data. Time series data include temperature, pressure, flow and other data. Non time series data include log data of industrial system and empirical data of production regulation. It data mainly includes business data such as enterprise resource planning (ERP) and manufacturing execution system (MES). The ERP system mainly includes financial, customer relations, supply chain management and other data. The MES system is located between the upper ERP layer and the lower control layer, and mainly includes production scheduling, quality management, personnel management and other data.

② Industrial data characteristics

"Isolation". Industrial data comes from multiple equipment of multiple processes. The equipment works independently and the data between processes is not circulated, forming "data islands".

Multimode. Industrial data sources are diverse and the structure is complex. In addition to the time series data of temperature, pressure and flow collected in industrial production, it also includes infrared thermal imaging video data for detecting flame temperature.

Strong association. The correlation in industrial data mainly includes: the correlation between production indicators, such as the correlation between raw material and fuel flow, temperature and pressure; The association of production processes, such as the association of process parameters between production operations; The relationship between product design and manufacturing, such as the relationship between simulation process and actual working conditions of the product.

"High throughput". The time series data collected by the sensor has the characteristics of many devices, many measuring points, high frequency, large throughput and continuous. Taking an industrial production equipment as an example, the data sampling frequency is 10Hz, and a single equipment generates 16kb of sensor data per second. According to the full collection calculation of 20 equipment, about 12.87gb of data will be generated every day, and 4.58tb of data will be generated every year, showing the characteristics of "high throughput". Data brings huge storage costs. There are also quality problems such as inconsistent connection, inconsistent standards, misaligned data, and "dirty" data, which can not provide an effective interface for data analysis. How to improve the data value density and data mining efficiency is an urgent problem to be solved at this stage.

2、 Research on industrial data governance system

① Top floor frame design

Data governance is the key to the road of industrial digital transformation. The implementation of data governance will help to improve the data value density, improve the efficiency of data mining, better serve flexible business scenarios, and provide an effective interface for data analysis. At present, the research on data governance system is quite mature and can be adapted to different application scenarios.

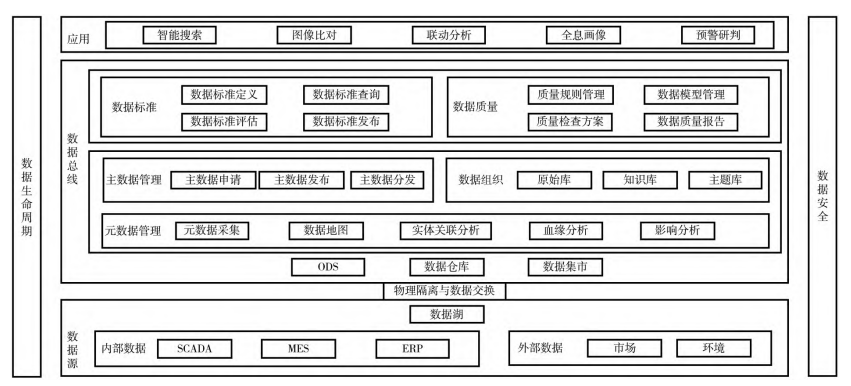

Figure 1 data governance system framework

In order to ensure no loss of data assets, the source data and analysis data are physically isolated. The source data is retained and stored in the local server according to the original format. The analysis data is stored after data governance, and the unnecessary data is archived or destroyed. The data governance system framework includes metadata management, master data management, data standard management, data quality management, data life cycle management, data organization, data security and data service links. The links cooperate and depend on each other to form a comprehensive, multi-level and multi angle data governance framework.

② Metadata management

Metadata is defined as "data about data". Metadata reflects transactions, events, objects and relationships of data. Through metadata management, data map can be drawn, data caliber can be unified, data orientation can be marked, data relationship can be analyzed, and impact analysis accurate to field level can be carried out to facilitate data tracking and backtracking.

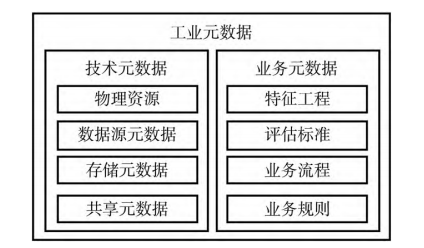

Figure 2 industrial metadata management

In the industrial field, metadata mainly includes technical metadata and business metadata. The technical metadata includes: physical resource metadata (server, operating system, etc.), data source metadata (gateway address, etc.), storage metadata (indicator description, data structure, storage attribute, management attribute, etc.), shared metadata (interface mode, format, etc.); Business metadata includes model metadata (Feature Engineering, evaluation standards, etc.) and analysis metadata (business processes, business rules, etc.). Based on industrial metadata management, a meta model can be built for metadata automatic collection to realize the functions of enterprise information asset sorting, data map, data kinship analysis, etc.

③ Master data management

Master data refers to the system shared data that meets the needs of cross department and cross business collaboration. It is reused in various business departments, such as customer, supplier, asset, product, bill of materials, account and other data. The industrial master data management process consists of business governance, standard governance and quality governance.

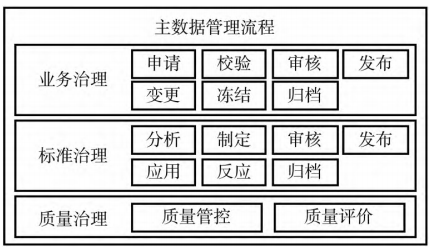

Figure 3 industrial master data management

In the field of industrial manufacturing, master data combined with IOT data can meet the needs of different business scenarios. For example, to understand or predict the inventory status of materials to improve production scheduling efficiency, you can associate the sensor data of raw material consumption with the master data of the bill of materials to sense the inventory status of materials. Therefore, by associating high-value, high sharing and relatively stable master data with IOT data, and combining machine learning, deep learning and other algorithms, the production and operation of enterprises can be evaluated in real time to make targeted adjustments.

④ Data standard management

The goal of data standard management is to design a set of standard system, including data quality standard, data operation standard and data application standard, so as to form a circulating and sharable information platform. Data standards are mainly composed of three parts: business definitions, technical definitions and management information. Business definitions include definitions of business, name and interface, technical definitions include definitions of data type and data structure, and management information includes definitions of owner and management personnel.

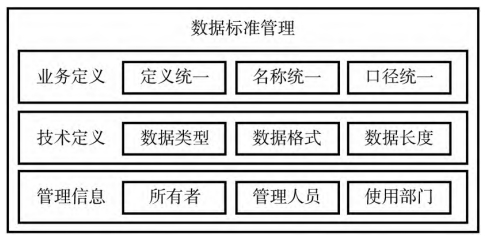

Figure 4 industrial data standard management

In the field of industrial manufacturing, big data standards are generally based on industry standards, such as metadata management standards (iso-11179, CWM, DCMI), data quality standards (iso-8000, iso-25012) and data security standards (iso-27001). They standardize data in combination with the characteristics of industrial data, generally including data format, data quality, data semantics, coding rules, dictionary values, etc., to reduce data islands, poor flow The occurrence of problems such as cumbersome application.

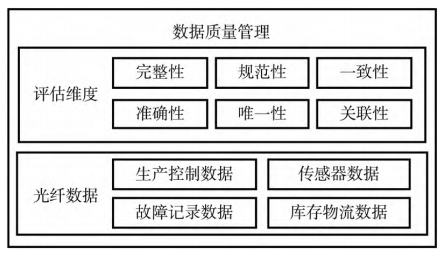

⑤ Data quality management

Data quality management is the key to industrial data governance and the premise of data application. It provides more accurate and high-quality data for enterprise risk control, analysis and decision-making, production and operation, and improves the efficiency of industrial data analysis.

Figure 5 industrial data quality management

The traditional quality evaluation system is too complicated. In combination with industrial data and business scenarios, a reasonable data quality evaluation system is built based on integrity, accuracy, standardization, uniqueness, consistency, relevance and traceability, and the quality evaluation system is refined according to the actual industrial production conditions:

Production control data: if the production control indicators are incomplete or inconsistent, or abnormal regulation is not timely, etc. Therefore, the data quality management of production control indicators should be prioritized to ensure the normal operation of the production process.

Sensor data: the sensor data monitors the operation in the production process, and can sense the abnormal production in real time, and optimize and adjust in time. Therefore, it is necessary to improve the timeliness and consistency of sensor data access.

Fault record data: in order to ensure the stable operation of production equipment, it is necessary to analyze and diagnose equipment fault records, so it is necessary to ensure the reliability and traceability of equipment fault record data.

Inventory logistics data: inventory logistics management is the basis of production, planning and control. By ensuring the timeliness and integrity of inventory logistics data, the production cycle can be optimized to ensure a virtuous cycle of production.

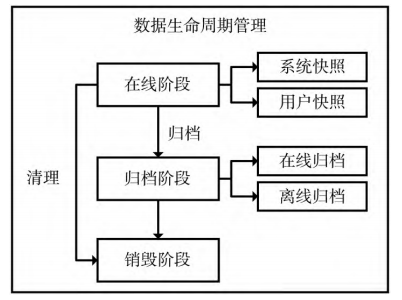

⑥ Data lifecycle management

Adopting scientific data lifecycle management can improve system operation efficiency, greatly reduce data storage costs and better serve customer needs. The data life cycle includes three stages: online stage, archiving stage and destruction stage.

Figure 6 industrial data lifecycle management

⑦ Data organization

The purpose of data organization is to build a data resource base based on the data application requirements and the scheme classification with unified standards and standardized processes, so as to further strengthen the internal association of big data. Data organization mainly includes original database, knowledge database, subject database, etc.

Original library: the original library saves the original business scenario data. The original industrial data mainly includes equipment monitoring data, production process records, product inspection data, abnormal production data and production operation data.

Knowledge base: the knowledge base refers to the collection of business experience data and rule methods in the industrial field, including data access, processing, services and knowledge data and rule methods involved in the general industrial model. Industrial knowledge base mainly includes raw material characteristics, equipment parameters, product design, production principles, industry trends, etc.

Topic Library: the topic library divides the original data and resource data according to the purpose of analysis and service to form a data set of different topics. Industrial data subject library mainly includes personnel subject library, equipment subject library, raw material subject library, production method library, production environment library, etc.

⑧ Data security

Most important and sensitive data in industrial production are concentrated in application systems, such as raw material formula, control strategy and other process parameter data, as well as production and operation data such as customer information, production plan and asset information. The impact of sensitive data leakage on enterprises is irreversible, highlighting the importance of data security in the process of data governance. Data security includes the following three points:

Data storage security: including physical security, system security and data storage security. Data storage security is mainly ensured through the purchase of security hardware.

Data transmission security: including data encryption and data network security control, with technical support provided by professional data security manufacturers.

Data use security: Based on the business system level, establish a perfect data security management system and review mechanism. Strictly manage all kinds of sensitive data used in production, R & D and testing.

⑨ Data services

Data governance is to make better use of data and is the basis of data application. Based on the business requirements of the industrial field, it is roughly divided into three directions: application support, tool application and business application. Application support services include knowledge map construction, data service bus and service management; Tool application services include production query and retrieval services, model analysis services and data management services; Business application services include service types such as product traceability, exception warning and large visual screen. Through the concentration, integration, mining and sharing of massive data, combined with the omni-directional and multi-level data service system, the real-time and forward-looking nature of exception handling is enhanced, and the transformation of industry to information and intelligence is promoted.

conclusion

As the supporting point of industrial digital transformation, industrial data governance system can greatly simplify data management process, reduce manual workload, improve data value density, improve data mining efficiency, provide high-quality data interfaces for different business analysis scenarios, and effectively promote the development of enterprises towards digitalization and intelligence.