15358968703

Exploration and practice of distribution matrix for No. 1 BF of Han steel

Abstract: the distribution matrix is an important means to adjust the burden system of blast furnace. Through continuous exploration and study of blast furnace distribution matrix, combining theory with practice, Han Steel No. 1 blast furnace has formulated a charging system suitable for the current peripheral conditions, ensuring the smooth operation of blast furnace conditions, and thus achieving the improvement of technical and economic indicators.

Keywords: cloth matrix; Material flow path; Gas utilization rate; Economic index of blast furnace

1. Introduction

Charging system is one of the four basic operating systems of blast furnace. The purpose of charging system is to realize the maximum utilization of gas heat and chemical energy by adjusting the distribution state of furnace charge in furnace throat and the rising gas flow according to the characteristics of furnace top equipment and the physical properties of raw fuel (Table 1). Through the adjustment of charging system, the reasonable operation furnace shape can be maintained, and the blast furnace can obtain high production, high quality, low consumption and long life. The adjustment of blast furnace distribution matrix is an important means to adjust the charging system. Through the study of distribution matrix, the distribution law can be scientifically analyzed, and the distribution equation can be used to calculate the material flow trajectory to achieve the most reasonable charging system [1].

2. Top equipment parameters of No. 1 blast furnace at Han steel

The effective volume of Han Steel No. 1 blast furnace is designed to be 1080m3. The series tank type bell less furnace top system is adopted. All valves of the charging system are driven by full hydraulic pressure. Two operation modes, automatic and on-site manual, are set to control the material flow valve by time and material level of the charging tank.

3. Distribution matrix correlation calculation

3.1 theoretical calculation of distribution track

In order to study the distribution scientifically, the distribution track is calculated according to the theory, and then combined with practice to explore the most reasonable distribution matrix. The throat area is divided equally. According to the principle of equal area concentric circle, the furnace throat section 11 is divided equally.

Total throat area s:

S=π(D/2)2=28.274m2 (1)

Where: throat diameter of D-1 blast furnace, 6m.

Area of each bisection ring s1:

S1=S/11-2.57m2 (2)

Thus, the radius of each ring and the distance to the center (Table 2) can be calculated, and the position of the center of each ring can be obtained.

3.2 distribution equation

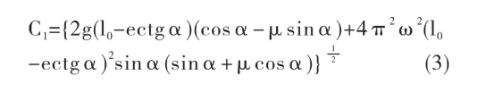

Speed of material at the end of chute

Projection of furnace charge leaving the end of chute on furnace throat section:

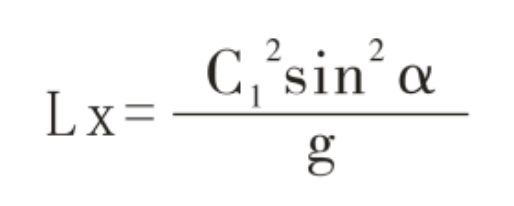

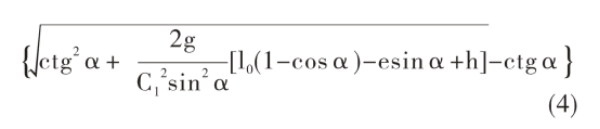

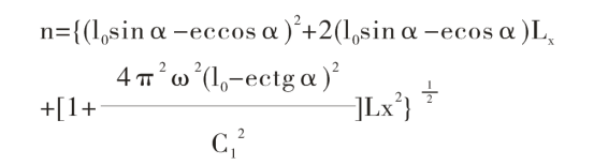

The actual distance from the center of the blast furnace after the furnace burden falls on the throat section, that is, the specific position of the furnace burden in the throat:

Where: a- distribution chute angle; Lo- chute length, taken as 2.5m; w

-Chute speed, 0.125r/s; E-chute tilting distance, taken as 0.5m; h

-Height from the material line to the vertical bottom of the chute, h=h1+h2; H1- height of operating material line, taken as 1.3m; H2- the distance from the vertical bottom of the chute to the zero point of the material line, taken as 1m; M-friction coefficient, coke friction coefficient is 0.3, ore friction coefficient is 0.53; G-gravitational acceleration, taken as 0.98m/s2.

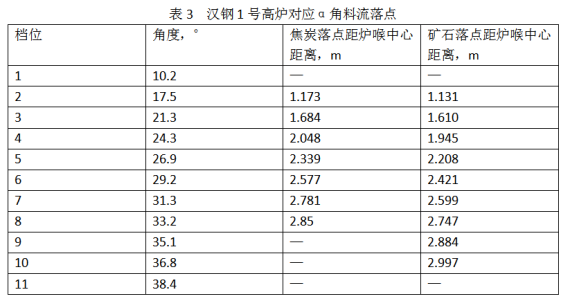

According to Liu Yuncai's distribution equation [2], the material flow trajectory of No. 1 blast furnace can be calculated, and then the actual a corner material flow point can be checked according to table 2, so as to facilitate adjustment and Optimization in combination with practice (Table 3).

4. Optimization Practice of distribution matrix

In the previous operation, No. 1 blast furnace emphasized the development of central air flow, and there was no excessive mining area in the center. Although a strong central air flow is formed, it is unstable and the gas is not well utilized, resulting in an increase in fuel ratio. The distribution matrix of No. 1 blast furnace has been continuously adjusted since early December in accordance with the air supply system (Table 4).

4.1 phase I

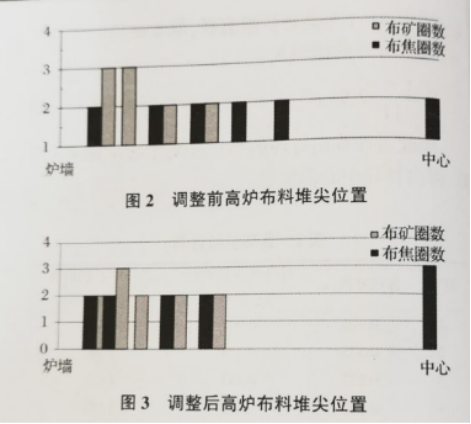

Because the designed bosh angle of No. 1 blast furnace is too large, the edge gas flow is easy to develop. It can be seen from table 3 and table 4 that before the adjustment, the outermost stack angle of the blast furnace during ore distribution is 25.3cm away from the throat steel brick. The distance is too large, which has poor inhibition on the edge air flow, and the air flow in one direction of the edge is often too strong in production. Through continuous exploration and practice, No. 1 blast furnace plans to push the ore coke gear outward at the same time (the distance from the furnace throat steel brick is reduced to 11.6cm), so as to form a platform with a certain width on the edge charge.

By properly weighting the edge, it can not only reduce the destructive effect of the edge gas on the furnace wall, which is conducive to the longevity of the blast furnace, but also improve the gas distribution and improve the gas utilization [3].

At the beginning of December, the adjustment was started to push the ore coke to the outer edge to dredge the central air flow and restrain the development of the edge air flow. At this stage, the furnace condition does not fluctuate greatly, but the air volume is less than before, and the utilization of gas is slightly improved.

4.2 phase II

On December 12, the coke secondary center ring was cancelled. It was originally planned to gradually reduce the proportion of central coke, but due to the deterioration of raw fuel conditions at this stage, the furnace condition was poor. It mainly shows: pressure holding, unstable air volume and material collapse. In order to ensure the smooth operation of the blast furnace, the proportion of central coke is increased. In practice, unexpected situations often occur (such as fluctuation of raw fuel composition, influence of peripheral equipment, etc.). In this case, first of all, ensure the smooth operation of the furnace.

4.3 phase III

From December 15 to 22, the central coke was gradually reduced.

Through the adjustment in the second stage, a strong central gas flow was formed, and the raw fuel conditions were improved, so the central coke was gradually reduced to 3 rings.

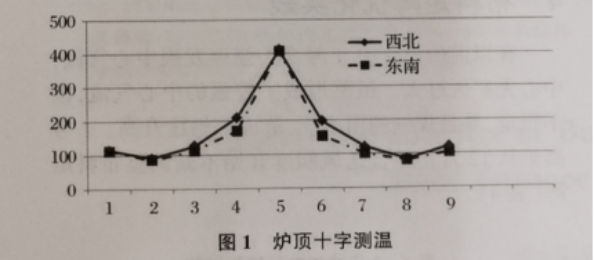

At this stage, the furnace is in good condition. According to the cross temperature measurement curve (Fig. 1), the central air flow is stable at 400 ℃. At this stage, the furnace temperaturerises automatically and the comprehensive load increases for many times.

4.4 phase IV

After December 25, the distribution matrix was fine tuned by observing the change of gas flow every day, and various economic indicators of the blast furnace continued to rise (Fig. 2 and Fig. 3).

5. Effect analysis of adjusting cloth matrix

The primary coke plus secondary coke has been used for a long time in No. 1 blast furnace of Han steel. Because the coke quality is poor and the composition fluctuates greatly, the utilization rate of gas has been low.

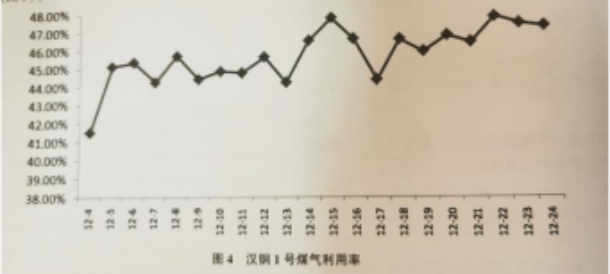

Through the continuous optimization of blast furnace distribution matrix, the gas distribution of No. 1 blast furnace has become more reasonable, and the gas utilization rate has been steadily improved (Fig. 4). The infrared monitoring of the furnace throat shows that the high temperature area in the center is obviously reduced, forming a stable and strong central air flow. From the cross temperature measurement, the edge air flow is reasonably restrained and the central air flow is stable; From the temperature curve of the furnace body, the temperature fluctuation of the furnace body is small, and the operation furnace type is becoming more and more reasonable.

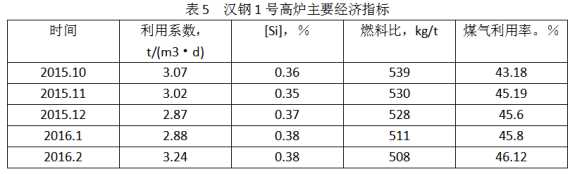

Under the existing raw material and fuel conditions, the economic indicators of No. 1 blast furnace are continuously improving through the research and practice of blast furnace distribution matrix (Table 5).

6. Conclusion

(1) To optimize the distribution matrix and adjust the loading system, we must combine theory with practice, and carry out practical operation through calculation and practice summary and in combination with our own characteristics.

(2) The adjustment of distribution matrix has certain limitations on the improvement of blast furnace index, which is greatly affected by raw materials and fuels. Because of the long-term use of secondary coke in No. 1 blast furnace of Han steel, from the results of practice, the effect of improving the gas utilization rate is limited, and other work needs to be done in the future.

(3) In case of changes in raw material composition and peripheral conditions, the distribution matrix and loading system shall be adjusted according to the situation, and the indicators shall not be blindly pursued. During the adjustment of No. 1 blast furnace of Han steel, due to the change of raw materials and fuels, the coping strategy was changed in time, and the furnace condition was not affected.

(4) The optimization of the distribution matrix must adhere to the guiding ideology of developing the center and giving consideration to the edges, so as to promote the smooth running and stability of the blast furnace.

(5) Han Steel No. 1 blast furnace has made some achievements in the exploration and practice of distribution matrix. In the next step, it should continue to optimize the operation and improve various indicators in combination with its own raw fuel characteristics.