15358968703

Preparation technology and properties of steel slag permeable brick

Abstract: steel slag is the main solid waste of iron and steel enterprises. With the development of China's modern metallurgical industry, the total amount of steel slag has also increased sharply. If it is not comprehensively utilized, it will cause serious pollution to the surrounding environment. Rational utilization of steel slag is of great significance to the development of iron and steel enterprises. In this paper, the modified qualified hot pressed steel slag is used as the main raw material, with a certain amount of cement and stone, the steel slag permeable brick is prepared by the non firing brick making process, and its performance is analyzed and tested, which can provide some data reference for the subsequent research and development of steel slag permeable brick.

Key words: steel slag; Permeable brick; performance

1. Foreword

Steel slag is the industrial waste produced in steel-making industry. With the rapid development of China's iron and steel industry, the total amount of steel slag has also increased sharply. However, due to the complex composition of steel slag and the large amount of free calcium oxide and free magnesium oxide contained in it, both of them will produce volume expansion after absorbing water. Among them, the volume expansion of Ca (OH) 2 generated by f-CaO is 98%, and the volume expansion of Mg (OH) 2 generated by f-mgo is 148%, resulting in poor stability of steel slag products and seriously affecting the product quality of steel slag products [1]. Therefore, the application of steel slag is limited, and steel slag is easy to be weathered into alkaline dust in the natural stacking process of slag yard, which not only occupies a lot of land, but also causes serious pollution to the surrounding environment [2]. Therefore, how to deal with steel slag to the maximum extent has become a major problem in the development of metallurgical industry. Research on the application of steel slag as pavement material at home and abroad shows that steel slag has high strength, good wear resistance, has the characteristics of concrete aggregate, and its mechanical properties are better than natural gravel. Moreover, due to the increase of particle irregularity, it has better stability and anti sliding ability [3]. As the main aggregate, the wear-resistant permeable brick made of natural sand, cement and other materials not only has certain strength, but also has certain water permeability. It can make natural precipitation rapidly penetrate the surface, keep the road well permeable and permeable, but also restore it to underground water, so that the underground water resources can be supplemented in time, the surface humidity can be adjusted, and the "heat island effect" can be suppressed [4].

In recent years, many problems have emerged in the process of rapid urbanization in China. The problem of urban waterlogging, which occurs frequently every year, is becoming more and more prominent. Most urban pavements in China are basically paved with stone, concrete or cement bricks. Although the hardened pavement is neat and durable, its biggest drawback is impermeability [5]. Therefore, the construction of "sponge city" can not only effectively alleviate the phenomenon of urban rain and waterlogging, but also reduce the urban heat island effect, improve the urban ecological environment and improve the quality of life of residents [6-7]. As the basic material for the construction of the "sponge city" project, the production technology of permeable brick has received great attention [8-10]. At the same time, a large number of large-scale industrial solid wastes such as steel slag and fly ash are discharged and accumulated, causing serious pollution to the environment, which is in urgent need of large-scale and resource-based comprehensive utilization [11-13]. Using steel slag as aggregate to prepare unburned permeable brick can not only consume industrial solid waste on a large scale, but also realize the low-cost preparation of permeable brick. It has the characteristics of energy conservation, environmental protection and resource recycling.

In this paper, the steel slag permeable brick was prepared by using the modified qualified hot pressed steel slag as the main raw material, together with some industrial raw materials such as cement and stone. The performance of the steel slag permeable brick was analyzed and tested.

2. Experimental scheme

2.1. raw material

2.1.1 steel slag

The steel slag used in this experiment is the steel slag after pool type heat sealing treatment after converter smelting in Caopu new area of Anning company affiliated to WISCO Kunming Iron and Steel Co., Ltd. after heat treatment and cooling, it is formed through primary processing such as crushing, magnetic separation and screening.

2.1.2 cement

The cement produced by Kunming Steel Jiahua Cement Co., Ltd. is low alkali cement with high early strength, stable late strength and low hydration heat

2.1.3 crushed stone

The gravel used in the experiment was purchased from Xishan District, Anning, Fumin, Luquan, etc.

2.2 process flow

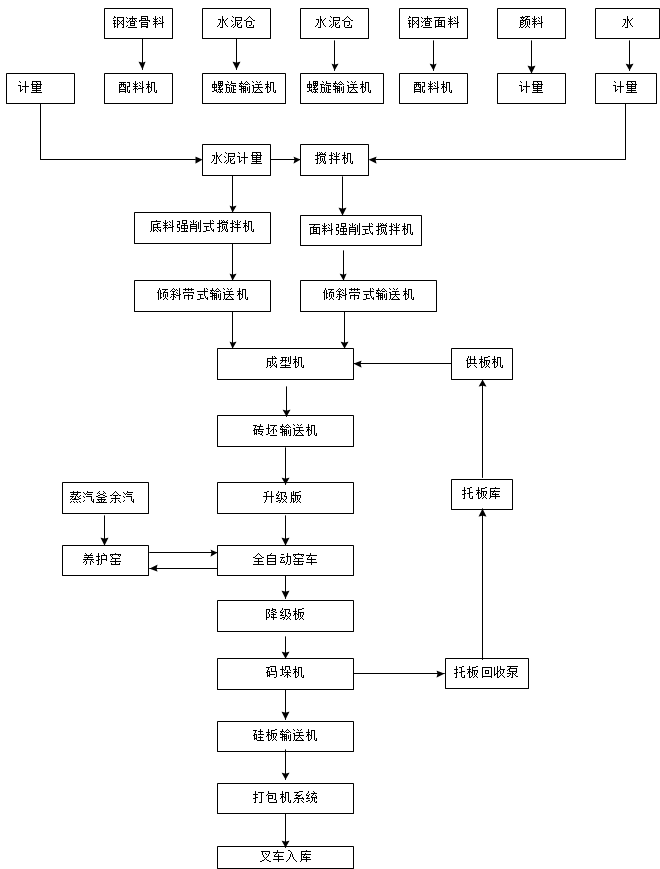

In this experiment, the full-automatic concrete unfired brick vibration forming production line is adopted. According to the mature and reliable grading formula, the steel slag permeable brick is produced by the production process of mixing raw materials, adding water, mixing and vibration forming. The production process is as follows.

Fig. 1 production process flow of steel slag permeable brick

3. Results and discussion

3.1 physicochemical properties of steel slag

According to the screening test, the particle size of steel slag in the new area of Kunming Iron and Steel Co., Ltd. after hot closed magnetic separation is between -9.5mm and +0.42, and the particle size range is suitable for making steel slag blocks. The chemical composition of steel slag is analyzed, and the results are shown in Table 2. It can be seen from table 2 that the main components of steel slag are Cao, SiO2, FeO, Fe2O3, f-CaO, etc., containing 5%-10% of metallic iron, and its water content is usually 3-8%. From the appearance, the steel slag is generally gray black, hard and dense, and light white when the alkali content is high. At the same time, steel slag macadam has the characteristics of high density, high strength, rough surface, good stability, good wear resistance and durability. Therefore, using steel slag as aggregate to produce permeable bricks has the characteristics of high strength and good water permeability.

The specific activity of radium-226, thorium-232 and potassium 40 of steel slag of Kunming Iron and Steel Co., Ltd. was tested by Yunnan epidemic prevention station. The IRA and iy of the steel slag were lower than the national standard, and the steel slag itself did not have radioactivity.

3.2 performance analysis of steel slag permeable brick

3.2.1 radioactivity analysis of steel slag permeable brick

Through the specific activity test of radium-226, thorium-232 and potassium 40 for steel slag permeable brick by Yunnan engineering quality monitoring station, the IRA and iy are lower than the national standard, and the steel slag permeable brick is safe.

3.2.2 analysis on compressive strength, flexural strength and permeability coefficient of steel slag permeable brick

According to recycled aggregate floor tiles and permeable tiles (cj/t 400-2012) and permeable pavement tiles and permeable pavement slabs (gb/t 25993-2010), 250 × two hundred and fifty × 60mm、300 × one hundred and fifty × 60mm and 600 × three hundred × The compressive strength, flexural strength and permeability coefficient of 150mm steel slag permeable bricks with three different specifications were tested. The test results are shown in Table 3. The results show that the compressive strength, flexural strength and permeability coefficient of permeable brick meet the grade requirements of the standard. The compressive strength and flexural strength are above 40MPa and 5MPa respectively, which are higher than the indicators of ordinary marble pavement. In addition, the steel slag particles have a certain porosity. After the permeable brick is formed, the stacking skeleton between the particles can form a gap. The porosity of the steel slag itself can also help the water permeability, so it can also ensure a certain water permeability [14], with a water permeability of 11%. In conclusion, the water permeability of steel slag permeable brick can meet the standard requirements, and its strength is also higher than that of ordinary permeable brick, which not only meets the load-bearing requirements of the pavement, but also achieves the effect of water permeability.

3.2.3 analysis on sewage purification effect of steel slag permeable brick

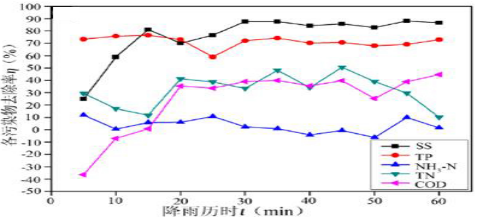

The water quality filtration test was carried out on 1m3 steel slag permeable brick (16.67m2 permeable brick is used according to 60mm thickness per square meter). The test results are shown in Figure 2. The removal rates of SS, COD, TP, NH3-N and TN by steel slag ecological permeable pavement brick were 76.2%, 24.1%, 71.2%, 3.25% and 31.9% respectively. The results show that, compared with the ordinary natural stone permeable brick, the steel slag permeable brick can intercept and remove the pollutants in the rainwater through physical filtration, absorb the remaining small suspended solids and part of COD in the water through porous adsorption, and remove the nitrogen and phosphorus in the rainwater through ion exchange precipitation. In addition, it can better regulate the acidity and alkalinity of the rainwater in the acidic areas in the process of rainwater infiltration.

Figure 2 sewage purification effect of steel slag permeable brick

4. Conclusion

Using steel slag as the main raw material, cement, crushed stone and other materials, the steel slag permeable brick prepared by the full-automatic concrete unfired brick vibration molding production line through mixing adding water mixing vibration molding has the characteristics of high strength, good water permeability and low production cost. Its pressure resistance and flexural strength are above 40MPa and 5MPa respectively, with a porosity of 30%. It has a high microporous water permeability effect, with a water permeability of 1.1 × 10-2cm/s, the annual rainwater interception of the pavement reaches 45%. In addition, the steel slag permeable brick has a variety of environmental protection characteristics, can purify the water quality, and has a good removal effect on SS, COD, TP, NH3-N and TN in the sewage. In general, the use of steel slag as the main raw material of green building materials plays an important role in improving the recycling rate of steel slag and synergistically eliminating the large amount of solid wastes of such steel slag. It can not only reduce the environmental pollution of soil caused by harmful substances in steel slag, but also save the exploitation of natural sand and gravel, opening up a new way for industrial waste slag to "turn waste into treasure".