15358968703

Practice of the treatment of the splashing in No. 6 BF of the Xi'an iron and Steel Co

Xilin Iron and Steel No. 6 blast furnace, with design effective volume of 1260m ³, There are two tapholes, and the East and West tappings in front of the furnace alternate tapping mode. The No. 6 blast furnace of Xi'an iron and Steel Co. was officially opened on July 25, 2013. After 4 days of opening, the smooth opening and rapid production were achieved through careful opening plan and careful opening operation. With the smooth start-up and production, the problem of iron mouth splashing is becoming more and more serious, resulting in heavy work tasks in front of the furnace and threatening personal safety, increasing the production cost of the blast furnace and sharply deteriorating the on-site environment. In order to solve the problem of iron mouth splashing, relevant personnel have comprehensively analyzed the causes for many times and formulated treatment measures. Based on the practical investigation and analysis of the comprehensive factors such as iron mouth working state, iron mouth equipment, gun mud quality and so on, it is considered that the quality problem of hearth carbon brick masonry, there are a large number of cracks in the masonry body and ramming materials, and a large number of cracks in the grouting materials during the solid-liquid conversion process, resulting in the gas channeling into the iron mouth channels, As a result, a large number of gas fires are ejected during iron tapping, resulting in the problem of iron mouth splashing. In this regard, the No. 6 blast furnace was treated by formulating a treatment plan. On october20,2013, the problem of iron mouth splashing was thoroughly treated, ensuring the normalization of production.

1. Iron mouth splashing and hazards

1.1 nozzle splashing

No. 6 blast furnace, design effective volume 1260m ³, There are 2 tapholes, and the two tappings in front of the furnace, East and West, alternate tapping mode. At the initial stage of production, both tapholes have splashing problems. When the taphole is just opened, the taphole will be splashed violently, and the slag iron flow is irregular. However, with the increase of tapping time, the phenomenon after slagging will weaken. Sometimes, the taphole splashing will run through the whole tapping process, resulting in too long tapping time.

1.2 nozzle splashing hazard

(1) As a result, there are a large number of tasks and dry slag in front of the furnace. Xigang No. 6 1260m ³ The blast furnace uses the iron storage type main ditch, the depth of the iron mouth is controlled at about 2.8m, and one of its advantages is that the amount of slag iron at the ditch side is small and the workload is small. However, due to the serious splashing at the iron mouth, a large amount of slag iron is sprayed outside the main ditch every time the iron is cast, resulting in a large amount of slag iron gathering at the ditch side. Before and after each iron tapping, the main ditch must be cleaned with equipment such as sledge hammer, steel drill, crown block, forklift and hook machine, It increases the labor intensity of furnace workers and equipment use cost.

(2) The safety and health environment in the work area is getting worse. During each tapping, a large amount of slag iron splashes. The splashed slag iron fills the site. After tapping, the slag iron must be cleaned, resulting in a large amount of dust. At the same time, when the iron mouth is just opened, the iron mouth splashes seriously, which may cause scalding of the iron workers near the furnace, affect the normal spot inspection of the equipment, and seriously affect the working state of the equipment.

(3) It interferes with the normal tapping in front of the furnace and affects the smooth operation of the furnace. The ejected slag iron causes residual iron hanging on the edge of the mud jacket, which is inaccessible to personnel during the tapping process, so it is very difficult to deal with. Therefore, after seeing the wind, the gun head protective pad can only be forced to block the iron port, which often causes the burning out or mud running phenomenon of the gun head protective pad, resulting in the iron port on one side, and the depth of the iron port can not be guaranteed. The tapping time is very uneven, and the iron content difference increases.

(4) Affect the quality of cast iron. Due to poor tapping quality caused by iron mouth splashing, it is difficult to guarantee the iron times, resulting in too long iron times interval. At the same time, the iron tapping time is different, and the iron tapping is uneven. The iron tapping amount is less than about 120t, and more than 360t, which seriously affects the iron tapping punctuality and iron content difference.

2. Cause and treatment process of iron mouth splashing

2.1 splash causes

Blast furnace taphole splashing is a common problem in the production process of blast furnace, especially in newly-built blast furnaces. There are few analysis data on taphole splashing in this industry, but the more recognized view is that the taphole channel forms a negative pressure. When the taphole channel forms a channel with the gas in the furnace, the gas flows into the taphole channel, and the gas locally explodes in the mud sleeve, causing taphole splashing. Therefore, to control the iron mouth splashing, the channel between the iron mouth channel and the gas must be blocked first. Path generation is analyzed as follows:

(1) Gap between cooling staves. The gap between cooling staves of blast furnace is filled with silicon carbide ramming material, with narrow gap, wide inside and narrow outside. The outer side gap is generally 20 ~ 30mm, and the inner side gap can be up to 80mm at most, so the tamping construction is very difficult. In the past, it was difficult to ensure the compactness by manual tamping. After the furnace was opened, the silicon carbide tamping material was heated and contracted, resulting in large gaps and forming a gas channel.

(2) Gap between each set of tuyere and tuyere composite brick. As the tuyere sleeve is made of copper, the thermal expansion coefficient is large. After the blast furnace is put into production, the tuyere sleeve and combined brick will expand due to the influence of temperature. In order to protect the equipment and eliminate the thermal stress, the buffer slurry needs to be filled between the tuyere sleeve and the combined brick, which also creates conditions for the formation of the channel.

(3) Gaps between fire-resistant masonry. The refractory bricks shall be filled and sealed with bond. If the mortar is not full enough, the brick joint will exceed the standard. In addition, the refractory used for the iron mouth channel is complex. The combination of carbon brick and corundum brick also brings great difficulties to the sealing of the iron mouth channel due to the difference of material properties.

(4) Gap between furnace shell and cooling stave. After the completion of blast furnace masonry, pressure grouting shall be adopted during furnace drying to increase the compactness. Some of the grouting materials will volatilize when heated, which will cause more cracks between the cooling stave and the furnace shell, and gradually form a gas path.

(5) The quality of blasting mud is poor. During the coking process, the strength of the gun mud was not enough, and radioactive cracks occurred with the center of the iron mouth as the center of the circle, which greatly accelerated the formation of the gas channel.

(6) Equipment defects. Insufficient dredging pressure will cause irregular iron port channels and unstable iron flow. During the operation of the personnel in front of the furnace, the improper use of impact and rotation, uneven diameter of the iron port channel, and the iron port that is not dried and damp will cause the iron port splashing. Therefore, the No. 6 blast furnace adopts the method of "from the outside to the inside, from simplicity to complexity" to solve the problem of iron mouth splashing. First, try the method with the lowest cost to eliminate the causes one by one.

2.2 governance process

The following is a summary of the governance process (in chronological order):

(1) Improve the operation level in front of the furnace and prevent iron tapping at the wet iron port. Each time, the iron port can stabilize the mud pressure and mud amount, but the iron port is still splashed seriously.

(2) The method of improving the quality of gunshot mud, increasing the mud pressure, increasing the mud quantity and protecting the mud bag was tried to control the iron mouth splash, but the effect was not ideal.

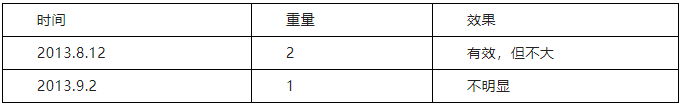

(3) For hearth grouting, it was found that the splashing inhibition effect was achieved by grouting for the East and West taps for many times by taking advantage of the opportunity of multiple wind breaks. The following is the statistics and analysis of hearth grouting data. Because the operation of cold face grouting is simpler than that of hot face grouting, short-term wind rest grouting can be used. It is analyzed that the filling of hot face ramming material in the masonry process is more controllable and has better sealing performance than that of cold face grouting. Therefore, cold face grouting treatment is first adopted for No. 6 blast furnace. Although it is effective, it is not obvious, as shown in table 1:

Table 1 materials and effects are as follows: /t

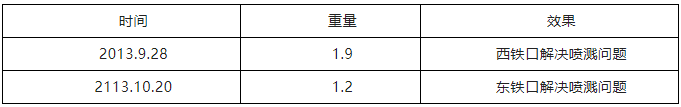

After the gap between the cooling stave and the furnace skin was treated, the hot surface between the cooling stave and the carbon brick was grouted, and it was planned to be treated after maintenance. This time, the carbon colloidal mud was used for grouting, sharing 25 barrels of materials, which basically solved the problem of splashing at the iron mouth of the west railway yard, but there was still a problem of splashing at the east iron mouth. On October 20, the blast furnace was shut down for grouting at the east iron mouth, sharing 16 barrels of materials. After the air was restored, The problem of splashing at the east iron port has been solved. So far, the problem of splashing at the blast furnace iron port has been basically solved, as shown in table 2:

Table 2 hot face grouting table is as follows: /t

Through the above measures, No. 6 blast furnace accurately and effectively found the problem, and solved the problem of blast furnace taphole splashing without affecting the production. In the subsequent production work, the taphole was prevented from splashing, the amount of dry slag was greatly reduced, the equipment and facilities in front of the furnace were effectively protected, the production cost was reduced, the tapping quality was improved, and the sanitary environment of the blast furnace was improved, It effectively ensures the physical and mental health of employees, and provides an effective guarantee for the smooth running of blast furnace and intensified smelting.

3. Summary

Iron mouth splashing is a common phenomenon in the production of blast furnace, and it is also one of the common phenomena reflecting the working state of hearth. If it is not effectively treated for a long time, it will seriously affect the working environment, production cost, tapping quality, etc. This time, the main influencing factors were found out for the nozzle splashing problem of No. 6 blast furnace of Xi'an iron and Steel Co., Ltd. and the problem was solved in a planned and organized way. Without affecting the production plan, the nozzle splashing problem was completely solved. The frequency and quality of tapping were stabilized, the output of blast furnace was increased, the production index of blast furnace was optimized, and the site sanitary environment was improved.