15358968703

Development of water-based large area mending material for converter

Hot repair materials are mainly used at the charging side, tapping side and bottom of the converter. They are necessary materials to prolong the converter life. There are generally two construction methods: ① investment and compensation. It uses manpower to carry out construction in the way of investment; ② Large area repair. That is, the charging hopper set on the converter console is used to pour it into the furnace, and then the furnace body is tilted to spread the furnace lining to be repaired with a certain fluidity after heating. After a certain period of sintering, it hardens to produce a certain strength and forms a solid bond with the masonry at the repair part. Therefore, the large surface repair material shall have good fluidity, sufficient construction time, rapid sintering and high bonding strength.

At present, the large surface repair materials for converter are mainly carbon bonded magnesia repair materials, which use tar and asphalt as binders. A large amount of black smoke is produced during the repair process, causing great harm to the construction environment and workers' health; At the same time, the sintering time of the make-up charge is long, which seriously affects the production rhythm of the steel plant and reduces the steelmaking efficiency. Therefore, it is of positive significance to develop water-based large area repair materials for converter. This paper describes a newly developed environmental friendly large surface repairing material for rapid sintering converter, and its industrial application.

test

1.1 raw materials and test plan

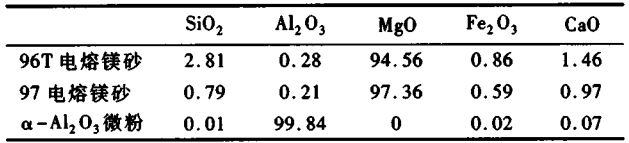

The main raw materials and chemical composition used in this test are listed in Table 1.

Table 1 chemical composition of main raw materials

The main raw materials used in the test are 96T fused magnesia with particle sizes of 5~3mm, 3~1mm and 1~0mm; 97 fused magnesia with particle size w0.088mm; A-al‹o ₃ micropowder and titanium dioxide; The binder is Elkem 95 silicon powder; The burning aids are boric acid and sodium silicate respectively; The retarder is citric acid; Superplasticizer Z, hexametakaolin and additive k-1 fine powder are used as water reducing agent.

1.2 test process and performance inspection

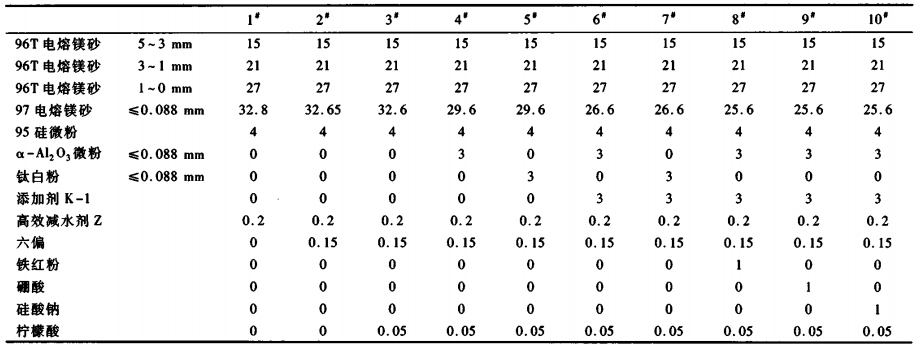

10kg of formula ingredients designed according to table 2 shall be mixed evenly, and then water shall be added to mix for 5min. The normal temperature flow value and high temperature flow value shall be measured, and then the remaining mud shall be cast into 40mmx40mmx160mm sample blocks, and the bonding strength and other physical properties shall be tested.

Table 2 sample ratio

Normal temperature fluidity: place the truncated cone-shaped circular mold with an upper inner diameter of 70mm, a height of 60mm and a lower inner diameter of 100mm vertically on a smooth iron plate with a diameter of 300mm, load the mixed repair material into it, and then pull up the truncated cone-shaped circular mold vertically. After the repair material stops flowing, measure its normal temperature fluidity with the average value of two mutually perpendicular diameters.

High temperature fluidity: put the mixed repair material into a long handle round spoon with a lower inner diameter of 70mm, a height of 60mm and an upper inner diameter of 100mm, quickly pour the repair material into a 270mmx270mm iron bath preheated at 1100 ℃ in the electric furnace, take it out for cooling after holding at 1100 ℃ for 5min, and then measure its high temperature fluidity by the average value of two mutually perpendicular diameters.

Bonding strength: (1) select the magnesia carbon residue brick with slag, cut it into 40mmx40mmx80mm sample block, put it into one end of the 40mmx40mmx160mm triple mold, pour the mixed repair material into the other end, and measure the flexural strength of the joint between the repair material and the magnesia carbon residue brick after drying. (2) Cut 95 magnesia brick into 40mmx40mmx65mm sample blocks, put them into the two ends of the triple mold, pour the mixed repair material in the middle, and measure the flexural strength at the junction of the dry repair material and 95 magnesia brick. The flexural strength at the junction above is defined as the bonding strength at room temperature; The flexural strength of the joint measured after high temperature treatment is defined as high temperature bonding strength.

Physical properties: the mixed mud is vibrated into a 40mmx40mmx160mm mold, demoulded after curing for 24h, then dried in 110t for 24h, and heat treated at 1100 ℃ and 1500 ℃ for 3h. The bulk density, normal temperature bending strength, normal temperature compressive strength and high temperature bending strength are measured according to yb/t5200-2008, gb/t3001-2007, gb/ t5027-2008 and gb/t3002-2004.

Results and analysis

2.1 influence of the addition of water reducing agent and retarder on the fluidity of repair materials

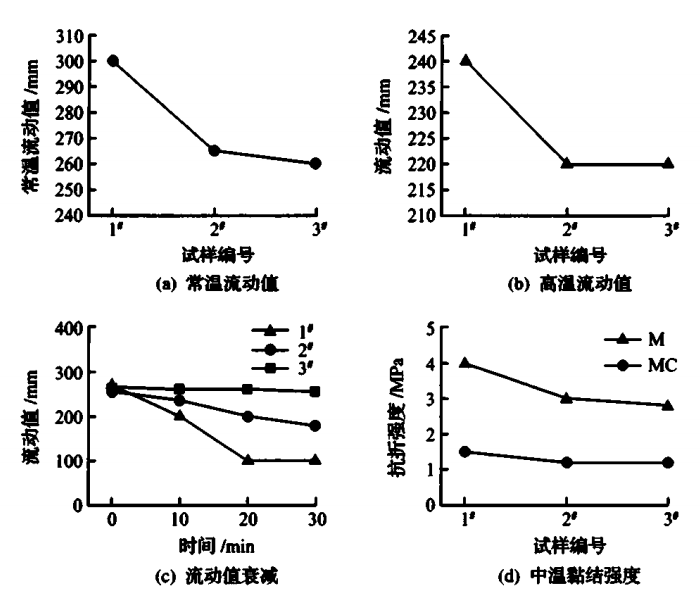

The influence of the addition of water reducing agent and retarder on the normal temperature fluidity, flow value attenuation, high temperature fluidity and medium temperature bonding strength of the repair material is shown in Figure 1.

Fig. 1 Effect of the addition of water reducing agent and retarder on the normal temperature fluidity, high temperature fluidity, flow value attenuation and medium temperature consolidation strength of the repair material

It can be seen from Figure 1 that the normal temperature fluidity of the high-efficiency water reducing agent Z patching material is too superior, but the mud is prone to bleeding, which will lead to the rapid decline of the mud fluidity and affect the field construction of the patching material. When high efficiency water reducing agent Z and hexametameric compound are used, the bleeding phenomenon disappears with the decrease of fluidity. Although the fluidity attenuation is slightly improved, it still can not meet the site construction. It can be seen from Figure 1 (a) and (b) that the law of normal temperature fluidity is the same as that of high temperature fluidity. It can be seen from Figure 1 (c) that with the introduction of retarder citric acid, the fluidity of the patching material decreases slightly, the fluidity attenuation is greatly improved, and there is almost no downward trend within 30min, which can meet the site construction. It can be seen from Figure 1 (d) that the repair material has a certain bonding strength, so there is no need to worry about falling off due to failure to bond with the large surface of the converter during construction. As citric acid is a waterproof additive, MgO particles contact with mixed water to form mgoh* ion group and then quickly adsorb citrate ions to form a low solubility magnesium citrate protective layer. The formed film prevents the hydration of magnesium oxide, thus playing a role in retarding the setting and improving the rheology and workability of castables.

2.2 effect of the addition of a-al‹o ₃ powder, titanium dioxide and k-1 on the fluidity and high temperature flexural strength of the repair material

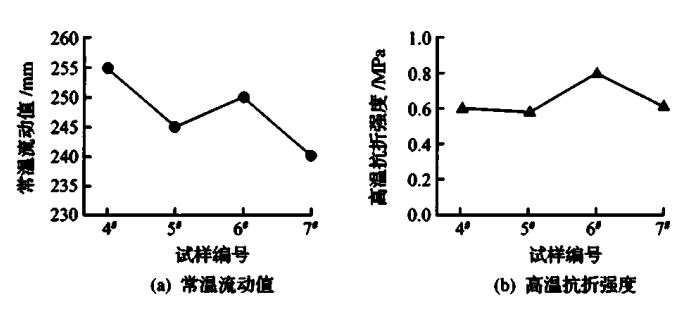

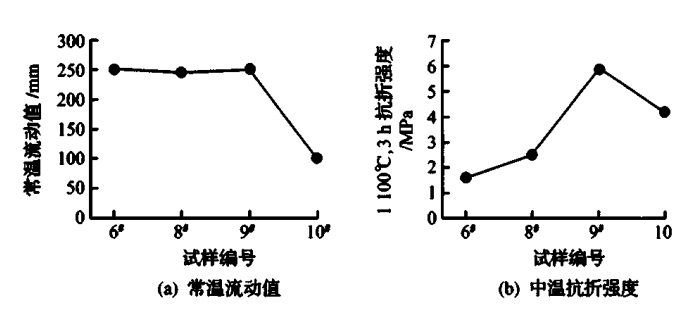

The effects of the addition of a-al‹o ₃ micro powder, titanium dioxide and k-1 on the fluidity and high temperature flexural strength of the repair material are shown in Figure 2.

Fig. 2 Effect of the addition of a-al‹o ₃ powder, titanium dioxide and k-1 on the fluidity and high temperature bending strength of the repair material

It can be seen from Figure 2 that the fluidity of the micro powder repair material did not decrease significantly and the high-temperature flexural strength did not meet the required value when a-al‹o ₃ was added; The fluidity of the repair material added with titanium dioxide showed a downward trend, and the high-temperature bending strength did not improve; When a-al‹o ₃ micropowder is used in combination with k-1, its flow value can meet the construction requirements, and its high-temperature flexural strength reaches the highest; When titanium dioxide and k-1 are used together, the flow value is the lowest and the high temperature bending strength is not significantly improved. Due to the fine particles, large surface free energy, many lattice defects and high activity of silica powder, it is easy to have Mullitization reaction with alumina in high alumina refractories at medium and high temperatures, so as to improve the post burning strength of the repair materials at medium and high temperatures; On the other hand, the addition of a-al‹o ₃ micro powder can play a filling role, reduce the apparent porosity of the castable, reduce the structural defects in the castable and improve its corrosion resistance; The added a-al‹o ₃ fine powder can also react with MgO fine powder in the repair material to form Ma, accompanied by certain volume expansion, making the structure of the castable more compact. After adding k-1, the high temperature bending strength of the repair material was improved.

2.3 effect of adding sintering aids on fluidity and medium temperature bending strength of repair materials

The influence of the addition of sintering aids on the fluidity and medium temperature bending strength of the repair material is shown in Figure 3.

Fig. 3 Effect of adding sintering aids on fluidity and medium temperature bending strength of repair materials

It can be seen from Figure 3 that the addition of iron oxide red powder has no negative effect on the fluidity and sintering of the repair material, but the improvement on the sintering is low; The addition of boric acid has no negative effect on the fluidity of the repair material, but the sintering property is greatly improved; The addition of sodium silicate can improve the sintering property of the repair material, but the fluidity of the repair material is greatly reduced, which can not meet the site construction. Boric acid has the trend of phase transformation at relatively low temperature, which may produce boron rich liquid phase, so as to improve the sintering reaction of repair materials. Amorphous boron oxide has no fixed melting point. It begins to soften at 325 ℃ and becomes liquid at 500 ℃. Moreover, the existence of this liquid phase in the composition of the repair material can help the material transport (diffusion) faster and induce other components in the system to interact more easily, so as to improve the sintering.

Industrial applications

Considering all performances, the 6\n\e scheme was selected. The industrial test was carried out on a 100t converter in a steel plant to repair the obvious pits on the front large surface. 2T repair materials were used for each furnace repair. The sintering time was <30min, and the average service life reached more than 45 heats.

conclusion

(1) Adding citric acid can obviously improve the flow attenuation of the repair material, improve the rheology of the mud, delay the setting and reduce the construction time.

(2) After adding k-1 into the patching material, the high-temperature flexural strength was significantly improved.

(3) The introduction of sintering aids can improve the medium temperature flexural strength of the repair material without affecting its workability.