15358968703

Analysis of blast furnace ironmaking process and equipment maintenance

Blast furnace ironmaking is an important part of iron and steel production. The iron making technology currently used is: at high temperature, when carbon rises in the furnace, it reacts with oxygen in the air. This process can remove oxygen (and generate carbon monoxide) from iron ore. iron ore is obtained after reduction. The produced gas is exported from the furnace top, and the refined molten iron is discharged from the iron mouth. This kind of furnace has good technical and economic indicators, and has the advantages of low energy consumption and large production.

1. Analysis of blast furnace ironmaking process

1.1 process equipment

1.1.1 blast furnace

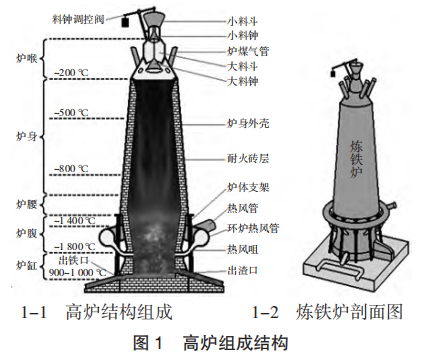

The cross section of the blast furnace is round, and the furnace body is relatively complex, which is divided into five parts from top to bottom: throat, shaft, waist, bosh and hearth. The specific composition is shown in Figure 1.

The blast furnace shell is lined with refractory bricks. During use, iron ore, limestone and coke are loaded from the top of the furnace. The blast furnace dust collector mainly absorbs the dust contained in the gas, and the gravity dust collector can absorb coarse dust (>60~90 μ m) The gas washer mainly absorbs fine dust. Secondly, the blast furnace blower can directly provide the oxygen required in the smelting process. It is the most important power equipment, which can ensure the combustion of a certain amount of carbon. The unit furnace capacity is generally 2.1~2.5m ³/ min。

1.1.2 blast furnace hot blast stove

This device is a regenerative heat exchanger, and the maximum air temperature can reach 1450~1550 ℃. Technicians can improve the air temperature by optimizing the structure of the hot blast stove and air supply duct, and can also prolong the service life of the hot blast stove by improving the operation method of the hot blast stove.

1.1.3 blast furnace cooling device

The device can prolong the service life of the brick lining. The internal temperature of the blast furnace lining is up to 1550 ℃. In order to ensure the heat transfer in the lining, the blast furnace cooling device can be used to cool the slag into a protective slag skin.

1.2 operation system

During the operation in front of the furnace, technicians should use special equipment and various tools (clay cannon, slag blocking machine, etc.) to open the slag and iron ports respectively at the specified time, discharge the slag and iron, and flow into the slag and iron tank respectively through the slag and iron ditch, so as to complete the maintenance of the special equipment in front of the furnace. In the production process, blast furnace ironmaking is based on refined materials, and the sinter drum strength is required to be ≥ 71%~78%. If it is a large blast furnace, the coke drum strength M40 is ≥ 78%~86%. According to the code for design of blast furnace ironmaking process, the basicity of sinter is maintained at 1.8~2.0. The space of coke in the hearth is 40%, and the air supply, charging, slagging and heating systems should be stable; In the process of reduction, melting and slagging, the gas distribution in the blast furnace should be adjusted; In the process of desulfurization, carburization and slag iron separation, we should always keep the hearth full of heat, and watch the combustion color of gas in time. Through the top camera and observing the top cloth during the wind off, we can judge the operation state of the blast furnace, optimize the selection of smelting intensity, and improve the oxygen enrichment rate and top pressure.

1.3 automation technology

Large blast furnaces led by Baosteel's No. 4 blast furnace are undergoing mass production. Under the realistic background of continuous updating and maturity of automation technology, new emission reduction policies are formulated, reasonable energy-saving and emission reduction measures are designed, basic automatic control system is optimized, and instrument panel data is automatically adjusted, which can realize furnace condition detection, water leakage detection of tuyere and cooling stave, hot air temperature detection, slag iron state detection Coke moisture detection, sequence control of feeding equipment, automatic control of hot blast furnace replacement, etc., directly promote the development of China's iron and steel industry production to TRT automatic control, and finally complete the high-quality smelting process.

2. Maintenance of blast furnace ironmaking equipment

2.1 equipment spot check and maintenance

In order to prevent failures and ironmaking problems in the operation of blast furnace ironmaking equipment, the maintenance staff should improve the production quality, actively carry out equipment spot inspection and maintenance operations, formulate spot inspection operation plans, ensure that the spot inspection activities can be carried out smoothly, prevent the spot inspection path from being too long, reasonably arrange the spot inspection contents, implement regular and regular supervision on key equipment, especially optimize the operation control of the gas recovery system, Make data records of material gate valve, material flow valve and lower sealing valve. In the current maintenance process of blast furnace ironmaking equipment, there are still many front-line personnel who do not pay enough attention to the maintenance and management of the equipment, and even the equipment can not meet the requirements of ironmaking, and some technicians cannot perform spot check, maintenance and other work according to the specified standard process.

Therefore, during the maintenance of blast furnace ironmaking equipment, the daily maintenance of mechanical equipment should be done well. For example, in the maintenance of bell less furnace top equipment, technicians should strictly implement the five set standards of lubrication to ensure that there is no running, emitting, dripping and leakage, check the wear of charging tank lining plate, clean up the sticking ash in time, and it is appropriate to keep the reduction of lower sealing valve rubber ring 2~3mm; For the blast furnace blower equipment, it is necessary to check whether there is oil leakage in the fan and motor, whether the opening of the damper is consistent with the instrument, pay attention to the change of the motor current, analyze whether there is abnormal noise in the internal bearing bush of the motor, find out the cause in time when finding the problem, adjust the motor current according to the air volume, and check whether the lubrication circuit of each bearing bush is normal, so as to ensure the normal use of the blast furnace ironmaking equipment.

2.2 equipment repair and waste utilization

In order to give full play to the role of blast furnace ironmaking equipment, we should keep track of the equipment that has been maintained. The obsolete equipment that cannot be repaired should be updated in time to ensure that all indicators meet the production requirements. Take the repair of iron making blast furnace iron mouth frame burning through as an example. Due to the long-term effect of high temperature and high pressure on the iron mouth frame of blast furnace, high-temperature molten iron will splash out from the burning through part, which is easy to cause the problem of iron mouth burning through at high temperature, which is very dangerous. Therefore, at this time, technicians should make new iron mouth frame and pouring core, remove heat-resistant ceramic iron mouth composite bricks according to the actual iron mouth frame width, and cut the pouring mouth at the upper end of the new iron mouth frame, According to the angle of hot metal channel, weld the new iron mouth frame and furnace skin, re pressure grouting the furnace shell below the iron mouth, block the iron mouth pouring material inlet after completion, and then dry the pouring material. In the process of repairing the cooling stave, if the burning loss is not serious, just carry out simple surfacing to repair it, and then stick and weld the new furnace skin. The weld between the new furnace skin and the iron mouth frame body is required to be full, and finally complete the whole repair process. At the same time, technicians and managers should improve the design of the equipment in the future work, and determine that the distance between the center of the iron mouth and the side plate of the iron mouth frame should be more than 320mm, so as to prevent weld cracking. According to the basic principle of prevention first, pay attention to the ideological education of operators to prevent the recurrence of safety problems, so as to always maintain the normal operation state of feeding equipment, make equipment operation and fault records, and determine the operation scope and workload of each repair, maintenance and update, so as to better optimize and transform the equipment.

2.3 improve the level of technicians

Relevant departments and managers should actively carry out the knowledge training of maintenance personnel on equipment maintenance to improve the maintenance quality of ironmaking equipment. Maintenance personnel should have a certain sense of responsibility, actively absorb advanced experience at home and abroad in the process of installation, maintenance and commissioning, clarify their responsibilities, do a good job in advance management, in-process maintenance and post maintenance, strengthen the control of the production of blast furnace ironmaking equipment, build the production and operation archives of blast furnace ironmaking equipment according to the strict periodic inspection and maintenance cycle, and improve the normal operation life of the equipment through refined management means. In addition, technicians should implement the daily spot inspection and maintenance of equipment, carry out a comprehensive inspection of the production situation, use the new energy-saving and emission reduction technology of blast furnace ironmaking process when necessary, pay attention to the development and utilization of new energy, realize the innovation of blast furnace in ironmaking process, and minimize the waste of energy.

At the same time, it is also necessary to let every employee firmly establish the idea of safety first, carefully design the repair plan, especially for weak links, and take preventive measures in time to finally realize the standardization of operation safety management. In the post event management, we should use the methods of spot check supervision and regular supervision to do a good job of safety disclosure, master modern maintenance technology, combine prevention and management according to the guidance of the latest scientific theory, correct the working mentality of technicians, and achieve full supervision and coverage.

3. Conclusion

The furnace body of blast furnace ironmaking is relatively complex, and the blast furnace equipment is relatively dense in the smelting process. Therefore, front-line workers and technicians should carry out a comprehensive physical examination of the production situation, improve the maintenance quality of ironmaking equipment, make full use of automation technology, promote the development of China's iron and steel industry production to TRT automation control, always maintain the normal operation state of feeding equipment, and make equipment operations and fault records, The equipment shall be overhauled regularly in strict accordance with the regulations, so as to achieve the combination of prevention and treatment, ensure the normal use of blast furnace ironmaking equipment, and finally realize the standardization of operation safety management.