650 steel rolling production line process description

一. Production scale and product plan

The proposed small and medium-sized hot rolled section steel production line has an annual production capacity of 50×104t.

2、Product scheme

(1) The main types of steel produced are: carbon structural steel, structural steel for Bridges, structural steel for hulls, low alloy structural steel, mining steel, weathering steel, etc.

(2) Product specifications: groove steel: 10 ~ 28#, I-beam steel: 10 ~ 28#, Angle steel: 12.5#- ~ 20#.

二:Production technology

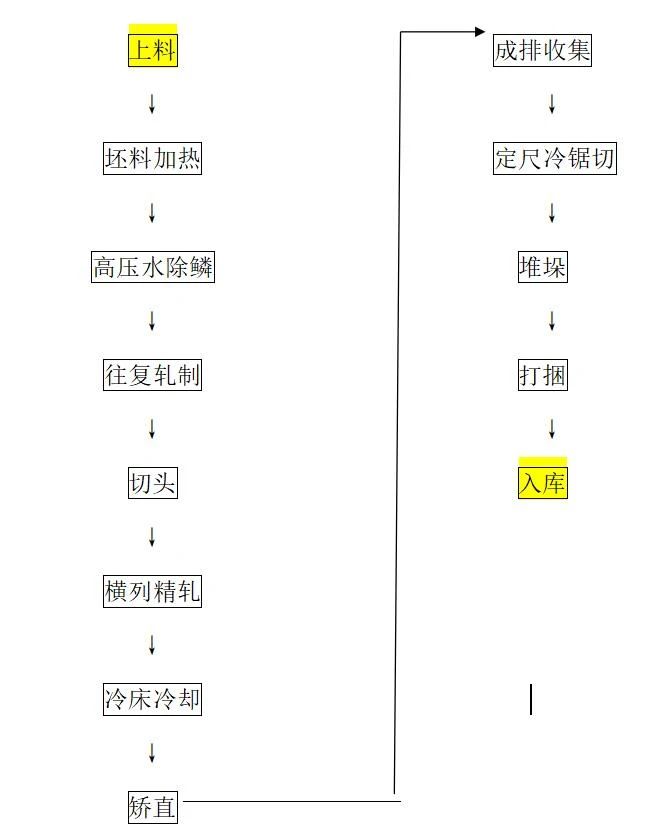

The main process consists of feeding, billet heating, (high pressure water descaling), rough rolling, finishing rolling, cold bed cooling, straightening, collection in rows, cold sawing at fixed size, bundling, marking, storage and so on.

2、Brief description of production process:

Qualified billets are sent directly to the input roller table of the heating furnace. After being sent to the heating furnace by the roller table, the billet is positioned by the fixed baffle plate and pushed into the furnace by the pusher machine. The unqualified billets are manually removed on the hearth roller table.

The heating of the billet is carried out by pushing wire type heating furnace with single row heating. The billet is heated in the furnace, and when the billet is heated to the specified temperature (about 1250 ° C), only one billet is sent to the outside of the furnace to the oven roller at a time according to the requirements.

Before rolling, the high pressure water descaling device uses high pressure water to clean the oxide sheet on the billet surface to avoid the pressing of the oxide sheet during the rolling process, so as to ensure the quality of the final product. The descaling box is a steel plate structure, including a chain curtain at the exit, a side guide plate and a replaceable nozzle ring. High pressure water can be controlled automatically. When the billet passes through the descaling box, the nozzle automatically ejects high pressure water with working pressure of about 17MPa to remove the iron sheet on the surface of the billet.

The nozzle is a box structure, and different sizes of nozzle rings can be selected according to a variety of different specifications of billets. The nozzle ring is connected to the water supply line by a quick coupling.

The billets removed from the oxidized iron sheet are sent to the 650 roughing mill through the input roller table for reciprocating rolling. The roughing mill is driven by a 3200kW AC motor. According to different product varieties and specifications, the rolled pieces are rolled 3 to 7 times on the roughing mill.

The roughing mill is semi-automatic and manual in the rolling process.

The finishing mill consists of 2.5 650 mills, of which 2 650 three-high mills and 1 650 two-high mills are rolled in transverse arrangement. The rolled pieces are sent through the roller table to the 650 two-high finishing mill for final forming rolling.

The sheets were rolled into a cold bed. In order to save costs, the cold bed is a combination of anchor chain and pinto cold bed, and the high temperature section of the rolled part (850-600 ℃) is cooled on the cold bed. The cold bed area is about 12 ~ 20×65 meters. In order to improve the cooling speed and quality of the shape steel, a forced cooling system is provided on the bed surface, and the rolled piece can be strongly cooled as needed during the moving process: the rolled piece is cooled on the cold bed, and the temperature of the cooling bed is below 70℃. The lower cooling bed mechanism is a parallel support hand, which transfers the rolled piece from the cooling bed to the output roller table in one piece.

The lower cooling bed rolled parts are sent from the roller table to the on-line straightening machine for straightening. The straightening temperature is not higher than 80℃. The levelling machine is a cantilever roller in order to make the rolled parts enter the levelling machine smoothly, the levelling machine is provided with a horizontal guide roller with adjustable roll surface height and a vertical guide roller with adjustable opening.

The straightening roller is of combined type. With quick roll change function.

Straightener sheets are placed on collection racks in rows. The platform is a flat chain fast slow combination cold bed, the stage frame is parallel to the hand, the platform area is about 5 ~ 10×65 meters. In the process of moving, the number of rolled pieces can be controlled according to the need. The unloading mechanism is the lifting support hand, which transfers the rolled piece from the cold bed to the output roller table.

There are a number of fixed length cold saws, one of which is moved, set the ruler baffle after the fixed saw, sawing the steel length of 6 ~ 12 meters, the first group of rolled pieces because the head is cut off on the upper cold bed, only fixed length sawing on the cold saw, the tail of the rolled pieces must be cut off on the fixed saw when the fixed length sawing is completed.

According to the requirements of the product, the sawing is automatically set by the computer, and the sawing operation is automatically completed, that is, the single or row sawing is cut into a fixed size, and transported to the stacking table.

The diameter of the cold saw blade is 1500 mm, and it has the function of quick replacement of the saw blade, and the replacement time is less than 15 minutes.

Finished product inspection and labeling

After the sawn rolled parts are sent to the finished product inspection by the roller table, the width of the 1# and 2# finished product inspection table is about 14 meters, and the rolled parts below 12 meters can pass directly on the inspection table.

The shape and surface quality of the product is checked manually, and the inspector clearly marks the defective product so that the defective product can be sent to the waste collection desk. Qualified products are stacked.

The qualified steel is transported from the roller to the piler input roller and transferred to each stack for stacking. Each group of stackers includes a lifting inlet transport chain, a conveyor chain, a lifting device, a lifting platform for a separation baffle, a stacker, etc.

According to the product specifications, the stacking device can be stacked according to the number of roots and layers of each layer. The piler is operated manually or semi-automatically.

The bundles of finished products piled on the stacker are clamped and bundled manually. The bundles are made of wire or narrow strip steel with a diameter of 6.5 mm. For 6-12 meters of fixed length materials, four bundles can be bundled with two bundles per strip. After binding, it is transported directly to the finished product storage table through the roller table.

The metal plate is manually hung on the steel bundle, and then stored in the warehouse by the bridge truck. The stacking and delivery of finished steel products are managed according to production plans and orders.