15358968703

[technology] application requirements for four row tapered bearings of rolling mill

Four row tapered roller bearings are favored by mechanical equipment manufacturers because they can bear large combined radial and axial loads, and can operate stably with the shaft in clearance, meeting the requirements of rapid disassembly and assembly, and can be used independently (without auxiliary bearings) to directly reduce the width of the bearing box and the roll length. Therefore, this type of bearing is often used as the intermediate roll and work roll of the rolling mill.

The installation requirements of this type of bearing are more complex than other radial bearing. In addition to the necessary tolerance fit and installation sequence, the relevant fitting parts are required to meet the following requirements:

1、 Interference of cage

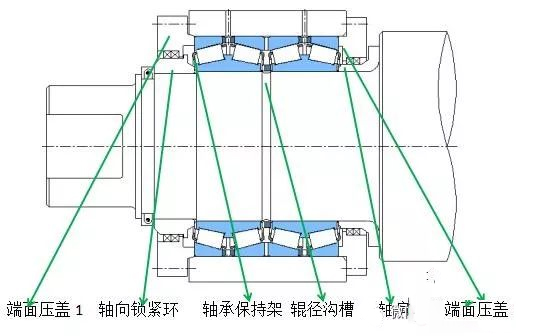

A typical 380000 four row tapered bearing is composed of two double row rolling element components (rolling element, cage and inner ring), a double outer ring, two single outer rings, two side spacers and an inner spacer.

Due to structural limitations, the cage often protrudes 2-7mm high from the inner and outer rings (different structures and size series, different protruding Heights), which often leads to interference between the mating parts and the cage, resulting in cage wear, jamming, deformation and other faults, and in serious cases, online burning and shutdown of the bearing. Therefore, it must be required that the fitting part size and the fitting spacing of the cage are appropriate. In particular, the following locations:

1. End gland 1 extension and cage

The fitting distance between the inner diameter of the end gland extension and the outer diameter of the cage protrusion shall not be less than 3.5mm.

2. Axial locking ring and cage

The fitting distance between the outer diameter of the axial locking ring and the inner diameter of the protruding part of the cage shall not be less than 3.5mm.

3. End face pressing 2 cover extension and cage

The fitting distance between the extension height of the end face gland 2 and the height of the cage protruding from the outer ring shall not be less than 4mm.

2、 Inner ring and axial compression ring

1. Keep an axial distance of 0.25-0.45mm between the end face of the bearing inner ring and the end face of the axial compression ring to reduce the wear of the end face of the inner ring and the end face of the compression ring; Slow down the harmful effects of bending roll inclination and thermal expansion on bearing inner ring and bearing capacity.

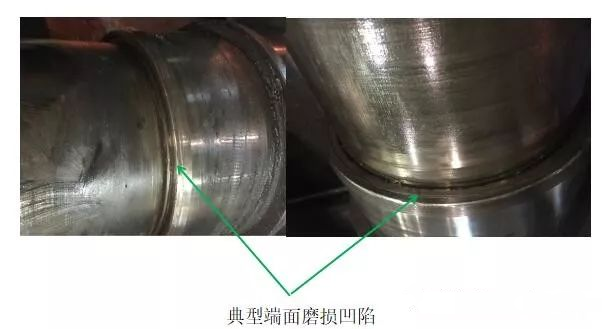

2. The outer diameter of the inner ring end face is equal to or slightly smaller than the outer diameter of the follower end face (≯ 3mm), so as to prevent the wearing depression of the follower end face caused by the wearing of the inner ring.

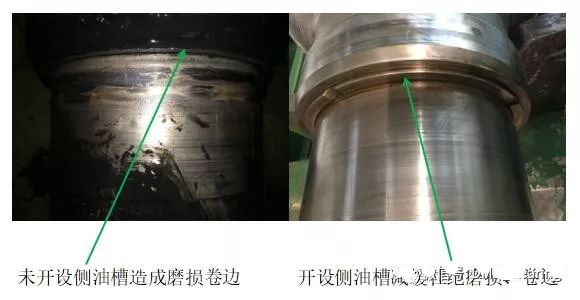

3. A side oil groove (circular groove) is set at the end face of the bearing inner ring or the end face of the hold down ring to increase the lubrication between the two end faces and also reduce the wear and crimping of each end face.

3、 Inner diameter and shaft diameter

1. On the premise that the inner diameter and shaft diameter can be matched to realize quick loading and unloading (quick loading when cooling and quick unloading when dismounting), the minimum matching clearance is maintained to reduce the wear of shaft diameter and bearing aperture; Reduce the sliding friction of the bearing inner race with respect to the shaft.

2. An oil groove (circular groove) is set at the joint of the two inner ring end faces of the shaft corresponding to the bearing to prevent the inner ring chamfer and the friction and roughening surface between the bearing spacer and the shaft diameter surface.

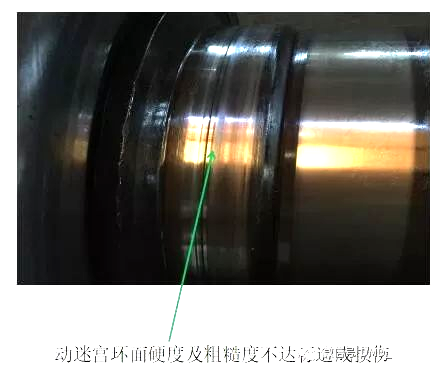

4、 Movable labyrinth ring (shaft shoulder) and inner ring

1. The outer diameter of the movable labyrinth ring (shaft shoulder) is equal to or slightly smaller than the outer diameter of the mating inner ring end face (≯ 3mm), so as to prevent the inner ring from wearing the movable labyrinth ring (shaft shoulder) and causing the end face depression, crimping and other problems of the movable labyrinth ring (shaft shoulder).

2. Side oil grooves (arc grooves) are set at the end face of the movable labyrinth ring (shaft shoulder) or the end face of the bearing inner ring to increase the lubrication between the two ends and slow down the wear of each end face.

3. The outer diameter surface hardness of the movable labyrinth ring (shaft shoulder) shall not be lower than hrc45. The roughness value at the contact with the sealing ring lip is recommended to be 0.25-0.5um to prevent mutual wear and damage with the sealing lip.

5、 Assembly height of bearing outer ring shall match with end face gland

1. Keep the assembly height of the outer ring and the covers at both ends in a tight fitting state to ensure the preset clearance of the bearing, especially in the working conditions with large radial load, such as the backup roll of the rolling mill.

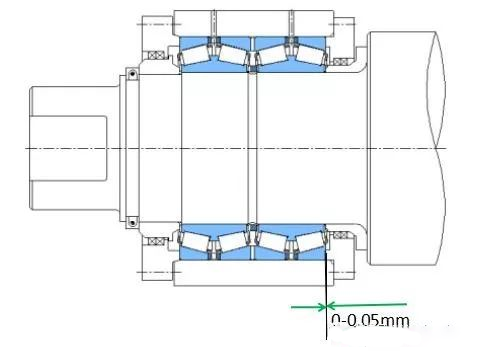

2. After replacing the bearing, it is necessary to readjust the fit between the outer ring assembly height and the end cover, and adjust the (non elastic adjusting plate) error compression or clearance of 0-0.05mm.