15358968703

Summary of abnormal damage of positioning bearing of 1200 cold rolling mill

The 351080/hcp53 rolling element and cage of the backup roll positioning bearing of the 1200 six high cold rolling mill in a factory are burned and locked periodically, which brings a lot of inconvenience to the use and assembly of the bearing, and often leads to the scrapping of the four row cylindrical bearings of the main machine, resulting in great economic losses.

In view of this problem, the technical personnel of the bearing manufacturer, after inspecting various indicators of the bearing, tracked the bearing assembly site of the factory from time to time on the premise of eliminating the bearing's own causes, and participated in the installation, disassembly and maintenance on site. Through tracking, the following series of related problems were found:

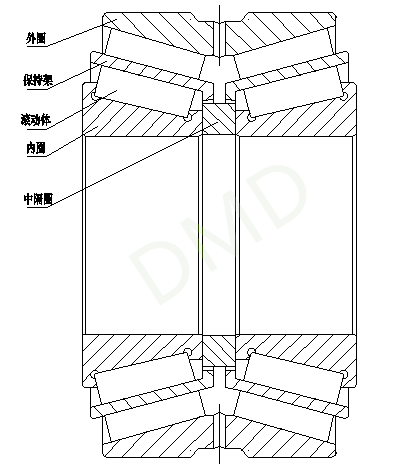

1、 Bearing structure

2、 Damage form of bearing

1. The row near the lock nut on the operating side of the backup roll is damaged, and there is no frequent damage on the corresponding side. In the early stage of damage, the large end face of the rolling element is worn, and the corresponding inner ring is discolored at high temperature.

2. At the later stage of damage, the large end face of the rolling element is bonded to the retaining edge of the corresponding inner ring at high temperature, and the cage is damaged and broken.

3. There is serious sliding wear in the circumferential direction of the end face of the middle spacer and the outer ring, and metal burrs and fine metal impurities are generated at the chamfer of the middle spacer due to wear.

4. Abnormal wear of main bearing flange and rolling element end face.

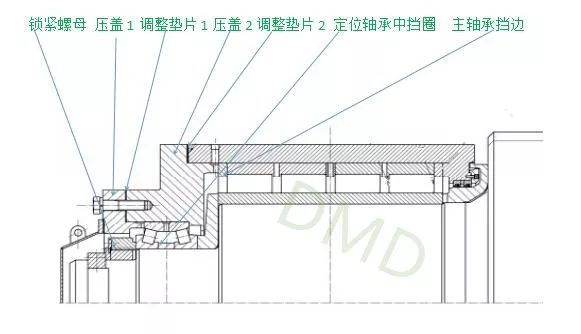

3、 Roll assembly structure

4、 Phenomenon analysis

By checking the above damage phenomenon and the stress analysis of the assembly structure, it is judged that the bearing is made up of the rolling element close to the lock nut side, which bears abnormal axial load, resulting in abnormal load on the end face of the rolling element and the flange end face of the corresponding inner ring, which leads to sliding friction. The friction causes the rolling element to strike horizontally, the cage to be damaged, and finally leads to the burning of the whole bearing.

According to the wear of the retaining ring and the end face of the outer ring in the bearing in the appeal picture, it can be determined that there is a gap in the axial compression of the positioning bearing. Then, the sub opening of the gland 1 and the adjusting pad 1 were measured, and the data are as follows:

1. Remove the gasket and install the gland 1 separately. When the pressure cover port is pressed against the end face of the positioning bearing outer ring, measure the clearance between the gland 1 and the gland 2 with a feeler gauge. The measured value is 3.2mm Then measure the thickness of the used rubber adjusting shim (flattened almost inelastic adjusting shim) to 3.9mm, and then measure the thickness of the unused adjusting shim to 4.2mm and 4.3mm. Through measurement, it is determined that after the assembly of bearing end cap 1, the thickness of gasket cannot be flattened to the ideal thickness (3.15-3.2), resulting in about 0.6mm axial clearance.

2. The axial clearance between the gland 2 and the main bearing was measured in the same way. It was found that there was also an axial clearance of about 0.6mm between the gland 2 and the bearing.

Further analyze the harm of axial clearance to bearing operation:

1. The axial clearance between the gland 2 and the main bearing will inevitably cause the centerline of the gland 2 to cross and tilt relative to the roll and roll box.

2. After the center lines cross, the outer ring of 351080 bearing inclines relative to the rolling element and inner ring. When the axial force acts on a row of rolling elements close to the lock nut (when the axial force acts in the direction of the transmission side), periodic axial overload and runout occur, causing bearing damage.

3. Similarly, after the relative inclination of the inner and outer rings, when the bearing is running at high speed, the cage will jump, the cage and the rolling element will be worn and vibrated, causing the cage to crack and the rolling element to strike horizontally, causing the bearing to burn and lock.

4. As a result, the main bearing retaining edge deviates and moves during operation, resulting in abnormal wear of the rolling element end face and the retaining edge end face.

5、 Rectification and adjustment

Bearing fittings:

1. Replace the existing accompanying rubber gasket with an adjustable rigid gasket.

2. During each assembly, the depth must be measured and adjusted according to the measured data to ensure that the axial pressure of the main bearing and the positioning bearing is reasonable.

3. Regularly adjust the bearing a/b bearing surface of 351080 to ensure synchronous wear on both sides.

Measure the data of the bearing spacer, and notify the bearing manufacturer to replace it if it is seriously worn, so as to ensure that the axial clearance of the bearing is reasonable.