15358968703

Discussion on optimization direction of super large cylindrical bearing

With the popularization of cold rolling six high mill and the improvement of AGC, the mill has been developing towards high load and high speed. The general linear speed can reach 800-1000m/min. When the mill is running, the backup roll bears all the radial load during rolling. The bearing is required to provide the maximum radial load and rigid support in the effective radial and axial space, which requires that the bearing must meet the requirements of high load, high rigidity and high precision in design, At present, fcdp four row cylindrical roller bearing is the preferred structure because its structure and characteristics meet the requirements of the main bearing of the supporting roll system of the rolling mill.

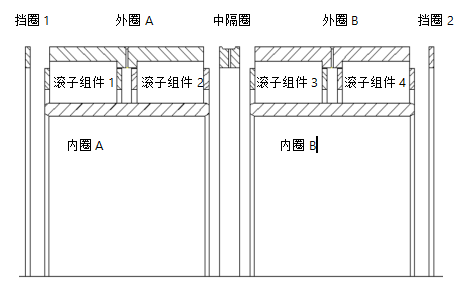

Bearing structure

As a typical rolling mill roll bearing, fcdp cylindrical roller bearing can provide maximum radial bearing capacity and low friction coefficient compared with other types of bearings in a given installation space. The bearing is composed of two movable retaining rings, one movable intermediate spacer ring, two outer rings, four row roller assemblies and two inner rings. Performance characteristics: high precision and high structural separation degree. The retaining ring and spacer are movable separable rings. The outer ring is close to the regular ring part, and the inner ring is a standard ring workpiece. Its overall parts are regular geometry, which is more convenient for the precision control of the workpiece during machining. The rolling element with strong bearing capacity is designed as a hollow structure. The cage pillar passes through the center of the rolling element, which saves the circumferential arrangement space of the rolling element of the whole bearing. Compared with the bearings of the same size series, the bearing can accommodate more rolling elements, greatly improving the bearing capacity of the bearing. The outer ring assembly and the inner ring of the partially interchangeable bearing can be separated. After installation, the outer assembly is installed in the bearing box, and the inner ring interference is installed on the roll journal. During use, the inner ring and the outer ring assembly can be interchangeable and universal. It is convenient to check that the inner ring interference is installed on the roll journal following the roll neck after disassembly, and the outer ring assembly is integrated with the bearing housing, which can visually detect the service conditions of key parts such as the bearing inner ring, rolling element and outer ring load area. It is easy to clean the bearing. The inner ring, outer ring, spacer and roller assembly can be separated. During machine cleaning or manual cleaning, the grease and foreign matters adsorbed on the surface of parts can be cleaned efficiently and quickly. According to the summary of market research, the following types of damage and differences exist in oversized cylindrical bearings:

1. After a certain period of service, the outer ring has a large deformation, and the average ellipse value is 0.15mm, which makes it difficult to install the outer ring for the second or third time, and it is directly impossible to install the outer ring if it is serious;

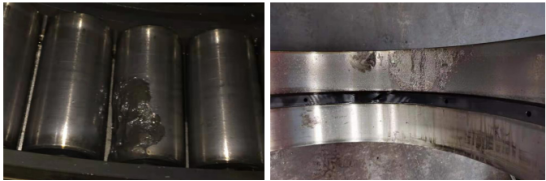

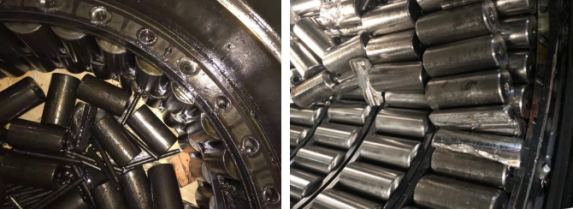

2. The design length, quantity and diameter of rolling elements differ greatly. The average diameter difference of rolling elements of the same type of bearing reaches 3mm, the average length difference reaches 8mm, and the average number difference reaches 10; 3. The rolling element and the retaining edge are grinded, and the rough edges of the rolling element and the retaining edge are grinded in the middle of use;

4. There are serious installation or disassembly scratches and gouges on the surface of the rolling element and inner ring;

5. Early fatigue damage of individual rolling elements or spalling of bearing area of single row raceway of outer ring;

6. The cage is damaged and desoldered, and the strut is broken;

Optimization direction 1. According to the fact that the outer ring is easy to deform and the radial load is large, it is necessary to adjust the wall thickness of the outer ring, properly adjust the section ratio of the rolling element to the outer ring, and thicken the outer ring. First, ensure that the bearing has enough rigidity to ensure that the elastic deformation of the bearing is infinitely reduced during operation, which can ensure the uniform distribution of load and improve the overall operating life of the bearing;

2. By adjusting the spacing between rolling elements, the spacing L between adjacent rolling elements can be compressed, and the space saved can be used to increase the number of rolling elements;

3. According to the objective existence of sliding friction between the retaining edge and the end face of the rolling element, strictly control the parallel difference between the retaining edge and the end face, strictly control the warpage deformation of the retaining ring, and strictly control the roughness value of the retaining edge contact end face;

4. The cage is a pure passive motion, which runs through the rolling element at the same time. It is necessary to accurately configure the clearance h between the cage strut and the rolling element hole, which should have the characteristics of easy lubrication and impact resistance. At the same time, it is necessary to strictly control the deformation of the cage components after connection (thread and welding) to keep the minimum, so as to prevent the rolling element from running track deflection;

5. According to the problem that the bearing needs periodic disassembly, the disassembly tools can be optimized or modified according to the structure of the bearing box and the field conditions of disassembly and assembly, so as to eliminate the collision damage to the bearing during disassembly to the greatest extent