15358968703

Installation and adjustment of guide

Adjustment of round steel and threaded guide:

1) Single line part

1. During the adjustment of all imported rolling guides, the guide roller of the guide must be consistent with the rolling center line of the guide (Guide center line), and the deviation of the guide roller is prohibited, which will lead to inaccurate import, easy damage of the guide roller and easy dumping of rolled pieces. For example, when the 12h inlet rolling guide is adjusted, the gap between the guide roller and the actual material type is about ± 10 wires; In other words, when adjusting the gap between the two guide wheels of the guide, use the actual material type to adjust, and it is best to show that the guide wheel can easily rotate with the sample bar. However, when the guide wheels on the left and right sides are consistent with the center line of the guide, and the clearance is appropriate, it is the best.

2. For example, when installing the 12h outlet sliding guide, it is best to have a clearance of 1-1.5mm between the scoop nozzle and the roll groove, that is, it is better to install without friction with the roll.

That is to say, the center line height of the inlet and outlet guide of the single line must be consistent with the center height of the rolling line, the left and right deviations must be consistent, and the installation must be three points and one line.

3. During assembly, the guide must be installed correctly and all fasteners of the guide must be fastened to prevent the guide from loosening and affecting the rolling process.

2) Double line part:

1. Adjustment of 16h outlet slitting guide. The adjustment of the slitting wheel shall be flush, and the adjustment gap between the two slitting wheels shall be about ± 10 wires (that is, it is OK to rotate the upper slitting wheel to drive the lower slitting wheel to rotate easily). The slitting blade shall be on the same central line with the slitting wheel and the imported splint, which is called "three points one line". Note: when the imported splint (shovel mouth) of the slitting guide is assembled with the roll, the clearance between the splint and the roll must be < 1mm.

2. 17h outlet torsion guide < 01-02 > adjustment. In the rolling process, the torsion angle of the torsion guide is adjusted according to the actual rolling speed and the actual rolling variety; The faster the rolling speed, the greater the gap between the two torsion wheels. It should be the best to measure the torsion angle of the torsion guide with the actual material type. When the rolling speed is faster, the actual sample bar shall be adjusted as follows α The angle is getting smaller and smaller. Generally, the angle is about 15 °. (during rolling, the following round bars can be used to adjust the gap between two rolls. For example: φ 22*2 shall be adjusted with round steel 22mm.) Use the sample bar to adjust respectively. During the adjustment, two torsion wheels can rotate with each other. It is easy to rotate and not too tight.

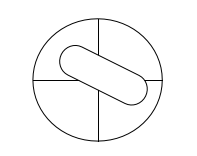

Angle diagram of outlet torsion guide:

3. During rolling (15 – 16), the guide wheels of the rolling guide (0930b/c) must be aligned with the left and right guide wheels respectively, and the guide wheels on each side must be consistent with the center line of the guide. Adjust the guide wheel clearance, adjust the guide wheel with the actual material type, and the four guide wheels rotate with each other, not too tight. Use the actual sample bar to adjust the guide roller. If the guide roller is easily rotating with each other, It is the best if the actual feeding bar moves slightly to the left and right of the guide (when there is no sample bar, the adjustment gap is about 0.5mm larger than the actual incoming material)

3) Bisection rolling:

1. In rolling( φ twenty-two × 2) For the rolling process, the precondition must be to ensure that the roll gaps between the left and right rolls of the mill are consistent, the wrong roll is prohibited, and the guide is properly installed. To ensure that the guide and roll are well adjusted is to ensure that the basic size of the material type is consistent. The key to the two-part rolling is the change of the material type. The material type must comply with the basic size to ensure the smooth rolling and the qualified products.

2. Guide installation and adjustment of dichotomy (dcr-2-00)

① Ensure that the two slitting wheels are installed correctly and that the two slitting toughness of the slitting wheel are flush;

② The adjustment clearance of the slitting wheel is ± 10 wires;

③ Ensure that the blade of the dividing box is basically flush with the tough mouth of the cutting wheel to avoid deflection and steel sticking;

④ The center of the two slitting inlet clamping plate (inlet shovel mouth) must be on the same line with the center line of the slitting wheel and the two slitting blade. Note: the gap between the inlet shovel mouth and the roll surface groove should be 1mm.

⑤ During rolling secondary slitting, the guide blade and slitting roll must be well cooled to avoid steel sticking due to too high temperature between the two slitting blades and natural annealing due to too high temperature in the center of the guide roll, which will affect the service life and rolling.

⑥ The second slitting guide must be installed correctly with the rolling mill, and the correctness of the material type can ensure the further solution of the problem; It is necessary to ensure that the adjustment of import and export guides is good, and the whole rolling system is good, so as to reach the production capacity smoothly.

3. The following problems often occur during rolling bisection:

(1) the two rolled finished products are not the same size. ① if one side is larger than the other, it is possible to adjust whether the 15h inlet is pre cut off. If the adjustment of the tangential inlet guide roll is too large, then check whether the roll gap at both ends is consistent; ② The phenomenon of high on the right and low on the left and high on the left occurs between 16h and 17h, and low on the right and high on the left from 17h to 18h. First, check whether the roll gap at both ends of the 17h roll is always, and then check the roll gap of the 18h roll.

(2) in case of steel sticking on the dichotomy guide, check whether the cooling is good. For example, if the cooling is good, check whether the rolling groove of the rolling line is too old. 15h and 16h, resulting in the enlargement of the slitting belt and the sticking of steel on both sides of the blade, which can not guarantee the smooth rolling of the rolling line. Therefore, we can consider whether the slitting wheel of the guide is broken.

(3) during the rolling process, the adjustment can be made according to the finished product. The rolling mill is basically adjusted in 3-4 hours, and the adjustment amount can be about 20-30 wires at a time, so as to ensure the basic normal of the material type, and the smooth rolling can be achieved.

Rolling conditions of slitting Guide

Ensure that 12h incoming materials meet the process requirements, and use 12V incoming materials to measure the material type of each pass of finish rolling, which shall meet the process requirements on the rolling table.

Ensure that the gap between the two ends of 13h roll is consistent.

The clearance of 14V inlet guide is consistent with the incoming materials. Ensure that the 14V material type meets the process requirements.

15h the gap adjustment of the imported rolling guide roller shall be consistent with the material type, and the guide shall be installed in the rolling groove to ensure that the material type meets the requirements.

16h is the same as 15h guide adjustment.

The roll clearance shall be determined according to the process requirements and the actual roll bounce.

For the cutting of 16h outlet guide, the cutting blade shall be aligned with the cutting wheel to ensure good lubrication and installation.

Ensure that the inlet and outlet guides of 17h are aligned with the rolling groove, and then make the roll gap meet the process requirements, and the roll gaps at both ends are consistent.

Ensure the correct installation and fastening of the import and export guides of the finished sorties.

4) Three line part:

1. Adjustment of 16h outlet slitting guide. The slitting wheel shall be adjusted flush, and the adjustment gap between the two slitting wheels shall be about ± 10 wires. The slitting blade shall be on the same central line with the slitting wheel and the imported splint, which is called "three points one line". The clearances of the three cutting blades are: φ fourteen χ 3, about 24mm. Note: when the imported splint (shovel mouth) of the slitting guide is assembled with the roll, the clearance between the splint and the roll must be < 1mm.

2. 17h outlet torsion guide (NA-1, 01-02) adjustment. In the rolling process, the torsion angle of the torsion guide is adjusted according to the actual rolling speed and the actual rolling variety; The faster the rolling speed, the greater the gap between the two torsion wheels. The clearances of guide rollers are respectively: < φ fourteen χ 3. It should be the best to measure the torsion angle of the torsion guide with the actual material type. When the rolling speed is faster, the actual sample bar shall be adjusted as follows α The angle is getting smaller and smaller. Generally, the angle is about 11.5 °. (during the rolling process, the following round bars can be used to adjust the gap between the two rolls. The 14mm Round steel sample bar can be used to adjust. During the adjustment, two torsion wheels can follow, which is not easy to be too tight.

Angle diagram of outlet torsion guide:

3. During rolling (15-16h), the guide wheels of the guide (0930b/c) must be leveled on the left and right sides, and the guide wheels on each side must be consistent with the center line of the guide. Adjust the guide wheel clearance, adjust the guide wheel with the actual material type, and the four guide wheels rotate with the actual sample bar. Do not be too tight, and adjust the guide roller with the actual sample bar. If the guide roller rotates with ease, It is the best if the actual bar moves slightly to the left and right of the guide (when there is no sample bar, the adjustment gap is about 0.2mm larger than the actual incoming material)

5) Trisection rolling:

1. In rolling( φ fourteen × 3) For the rolling process, the precondition must be to ensure that the roll gaps between the left and right rolls of the mill are consistent, the wrong roll is prohibited, and the guide is properly installed. To ensure that the guide and roll are well adjusted is to ensure that the basic size of the material type is consistent. The key to the three slitting rolling is the change of the material type. The material type must comply with the basic size to ensure the smooth rolling and the qualified products.

2. Installation and adjustment of guide and guard for three cutting (dcr-3-00)

① Ensure that the three slitting wheels are installed correctly and that the two slitting toughness of the slitting wheel are flush;

② The adjustment clearance of the slitting wheel is ± 10 wires;

③ Ensure that the two blades of the dividing box are basically flush with the two tough edges of the slitting wheel to avoid deflection and steel sticking;

④ The center of the three slitting inlet splint (inlet shovel mouth) must be on the same line with the center line of the slitting wheel and the three slitting blade. Note: the gap between the inlet shovel mouth and the roll surface groove should be 1mm.

⑤ During rolling three slitting, the guide blade and slitting roll must be well cooled to avoid steel sticking due to too high temperature between the two slitting blades and natural annealing due to too high temperature in the center of the guide roll, which will affect the service life and rolling.

⑥ The three slitting guide must be installed correctly with the rolling mill, and the correctness of the material type can ensure the further solution of the problem; It is necessary to ensure that the adjustment of import and export guides is good, and the whole rolling system is good, so as to reach the production capacity smoothly.

3. The adjustment of the inlet rolling guide and the outlet sliding guide of the trisection is the same as that of the single line. The torsion angle adjustment of outlet torsion guide < 01-02 > and two split torsion guide < 01-02 > is the same.

4. The following problems often occur during rolling three slitting:

(1) the three rolled finished products are not the same size, ① the middle is small and the two sides are large, so the 12V rolling mill should be pressed down; ② If one side is larger than the other, you can adjust whether the 15h inlet is pre cut off, if the adjustment of the tangential inlet guide roller is too large, and then check whether the roll gaps at both ends are consistent.

(2) in case of steel sticking on the three cutting guide, check whether the cooling is good. For example, if the cooling is good, check whether the rolling groove of the rolling line is too old. 15h and 16h, resulting in the enlargement of the slitting belt and the sticking of steel on both sides of the blade, which can not guarantee the smooth rolling of the rolling line. Therefore, we can consider whether the slitting wheel of the guide is broken.

(3) during the rolling process, the adjustment can be made according to the finished product. The rolling mill is basically adjusted in 3-4 hours, and the basic adjustment amount is about 20-30 wires at a time, so as to ensure the basic normal of the material type, and the smooth rolling can be achieved.

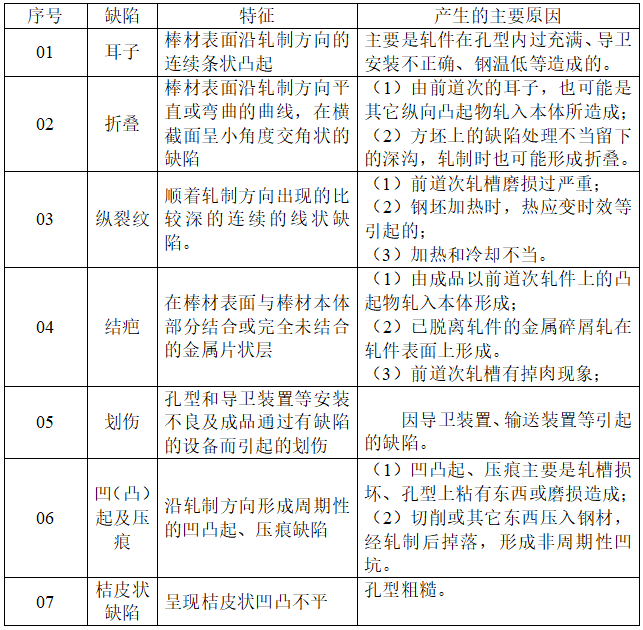

6) Common defects of product varieties and their causes (see the table below)