15358968703

Comprehensive characteristic analysis of blast furnace fuel injection

2022-06-28

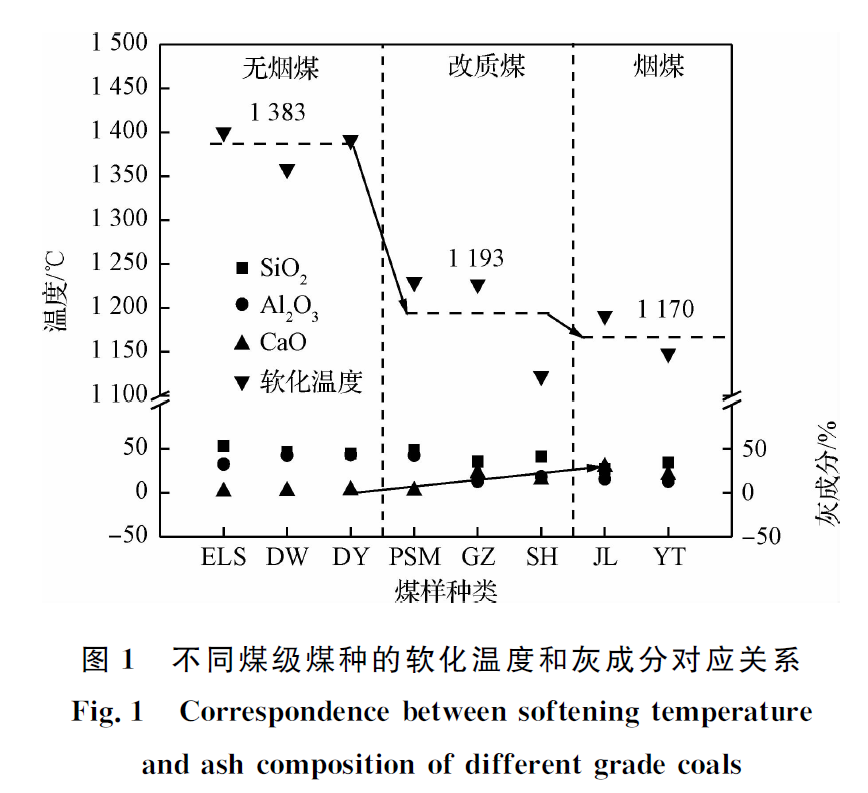

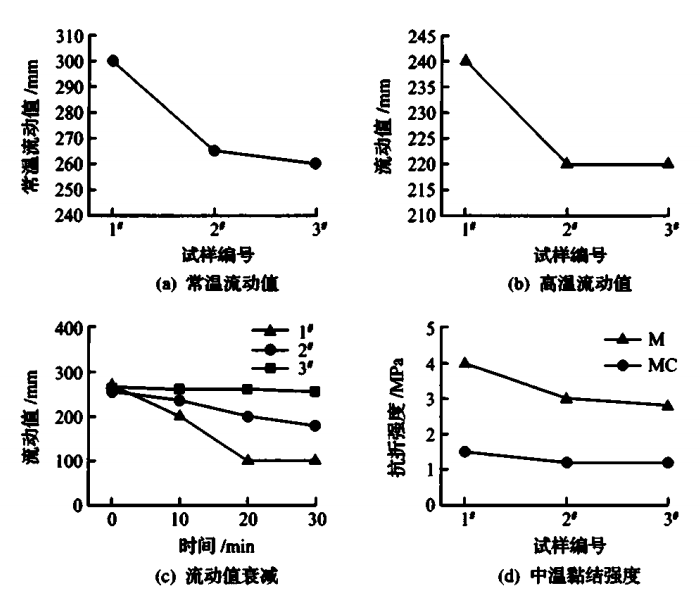

After decades of development, the technology of pulverized coal injection into blast furnace has become a common technical means used by major iron and steel enterprises at home and abroad. Coal injection into blast furnace p...

Operating procedures for guide fitter

2022-06-27

1、 Standards and parameters: 1. the guide box, guide pair, guide roller, wear plate, nose cone and other guide components of each Sorty shall be selected in strict accordance with the guide layout table. 2. the as...

Summary of teaching materials for rolling adjustment training

2022-06-27

Adjustment of roll gap Whether the roll gap adjustment is correct or not directly affects the stability of the rolling process, and also determines the size of the rolled piece outlet. The judgment basis of roll gap adj...

Development of water-based large area mending material for converter

2022-06-27

Hot repair materials are mainly used at the charging side, tapping side and bottom of the converter. They are necessary materials to prolong the converter life. There are generally two construction methods: ① investment and c...

Production practice of increasing tundish life at high casting speed

2022-06-27

Correctly view the influence mechanism of raw fuel quality on the smelting process of blast furnace, rationally analyze the operation trend of furnace condition, strengthen the screening management under the trough, do a good...

Analysis of end point control technology for converter steelmaking

2022-06-25

With the continuous development of science and technology in China, the quality of people's daily life is becoming higher and higher. At the same time, all kinds of energy resources are being produced frequently, and the ...